Garbage classification and collection system for high-rise building

A collection system and garbage classification technology, applied in garbage collection, trash cans, vertical pipes, etc., can solve the problems of difficult to accurately classify garbage, unsuitable corridors, secondary pollution, etc. the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

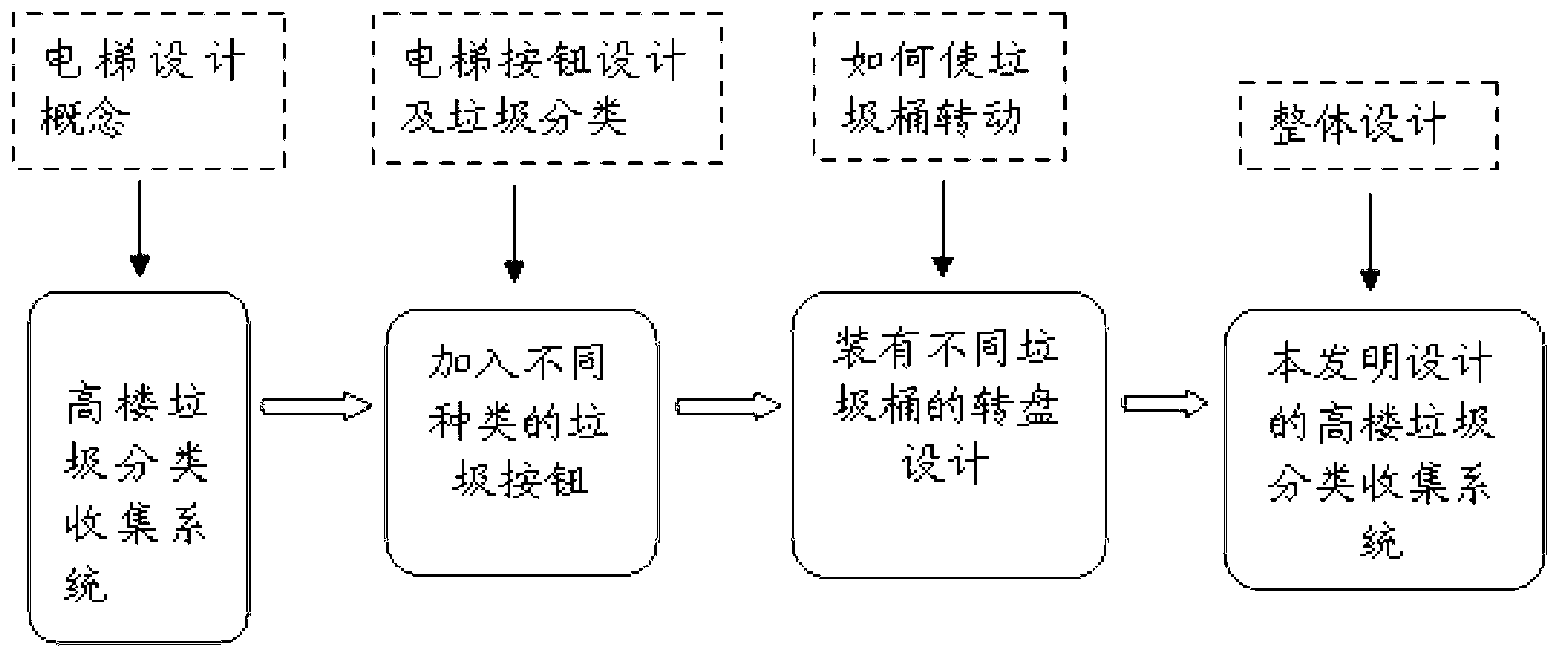

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

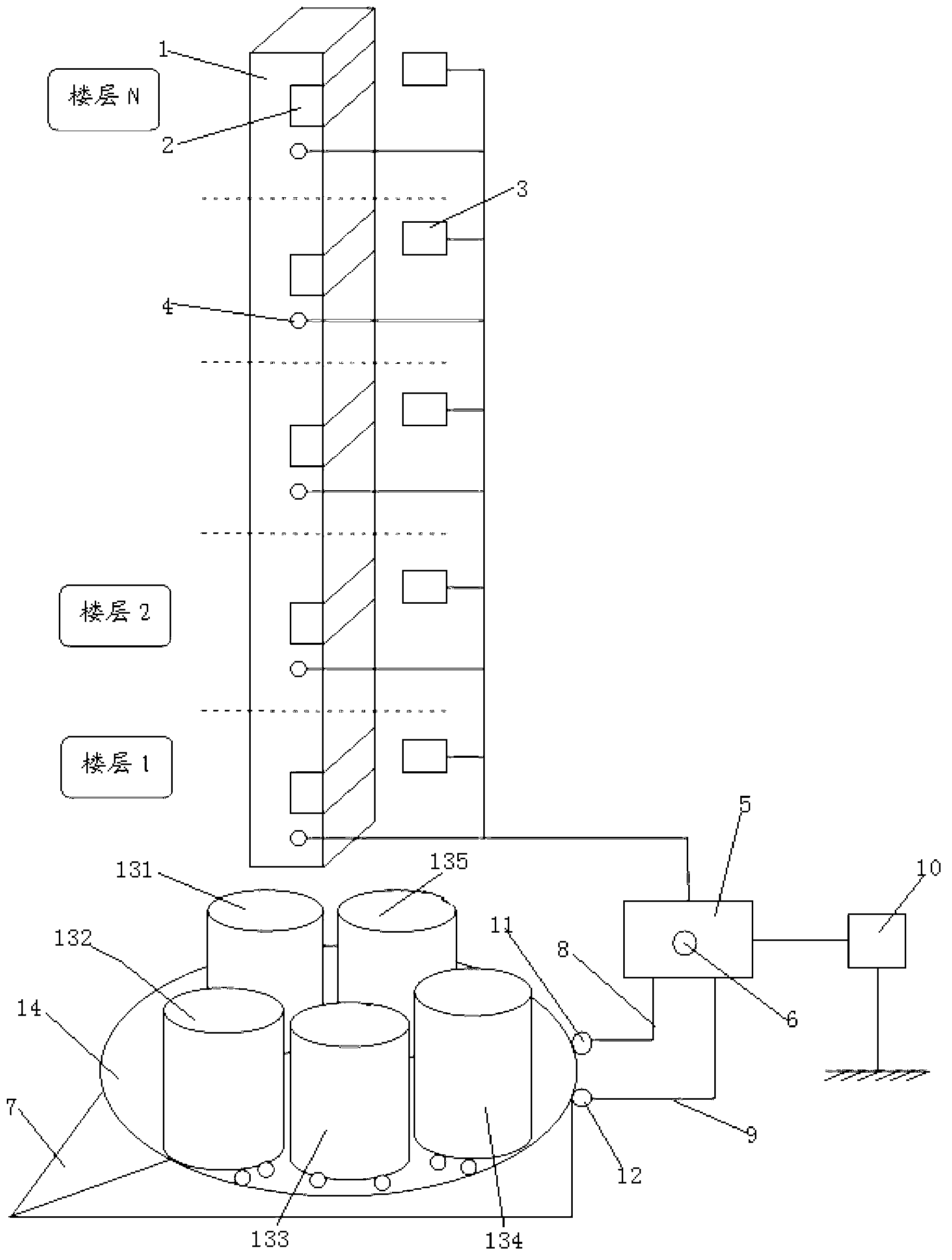

[0042] Such as figure 2 As shown, the present invention includes a vertical slideway 1, a control device, different types of garbage cans, and at least one lifter. exist figure 2 Each floor is distinguished by a dotted line, and at least two doors 2 are arranged on one side of the vertical slideway 1, and the number of doors 2 is consistent with the number of floors and corresponds to each other.

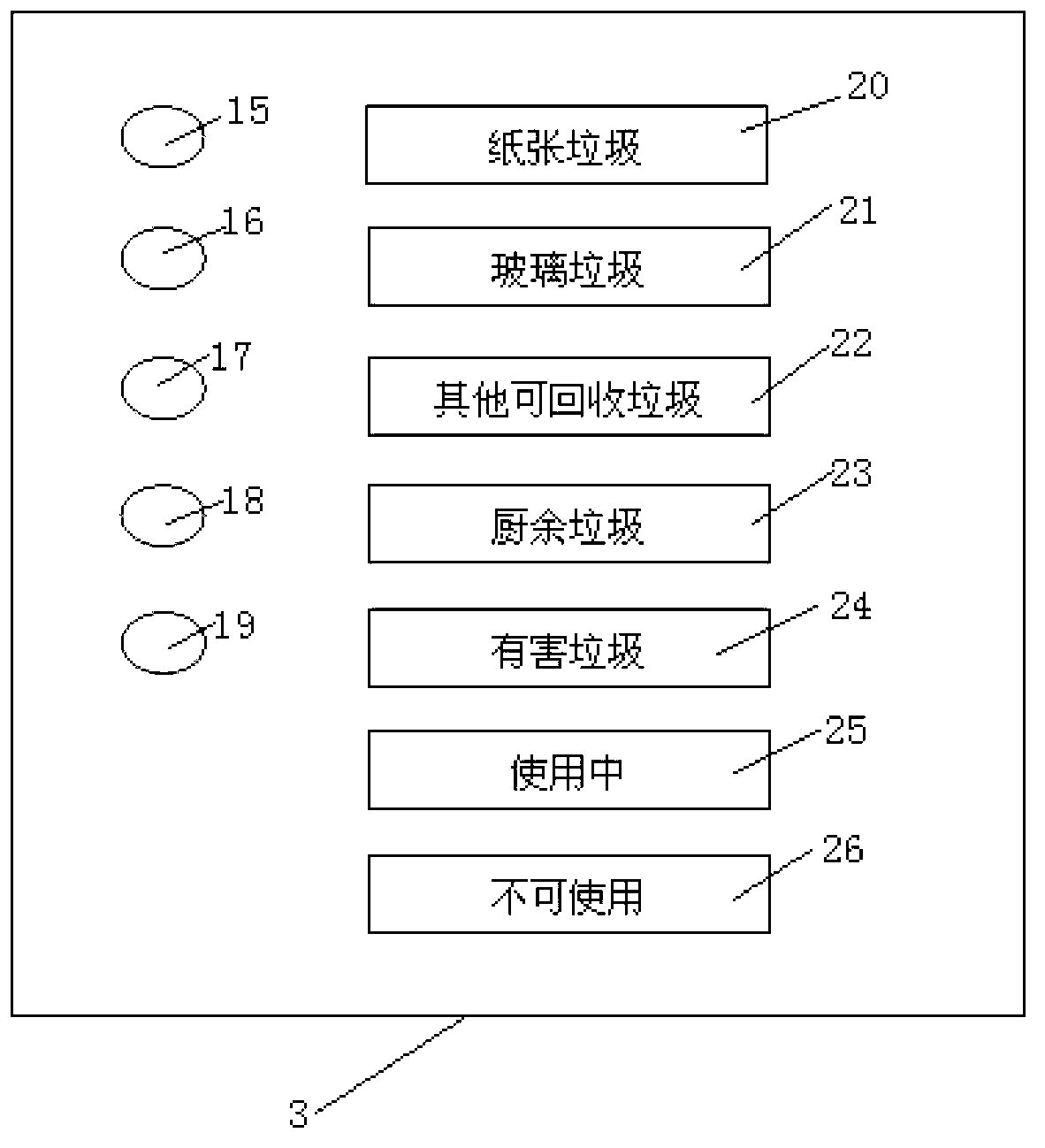

[0043] Such as image 3 As shown, the control device includes a control panel 3 arranged on each floor. The control panel 3 is provided with a sorting garbage button and an indicator lamp connected with the sorting garbage button and correspondingly displayed according to the received button signal. The sorted garbage button indicates buttons for different types of garbage, and each type of garbage can corresponds to a sorted garbage button, including but not limited to paper garbage buttons, glass garbage buttons, other recyclable garbage buttons, kitchen waste buttons and har...

Embodiment 2

[0052] The lifter does not have a turntable, and each type of underground garbage bin corresponds to a lifter, and the lifter is respectively arranged at the bottom of each type of garbage bin. Such as Figure 4 As shown, there are five independent lifters 33, and the five independent lifters 33 are respectively arranged in the kitchen waste trash can 131, paper trash can 132, other recyclable trash cans 133, harmful trash cans 134 and glass trash cans 135. bottom. Five independent lifters 33 are connected with the control panel 3 and the central controller 5 respectively. Each independent elevator 33 can move up and down in the vertical slideway 1, and can stop at each floor. Correspondingly, a single garbage bin is placed on the independent lifter 33 and moves synchronously, and stops on each floor. The lifting flexibility of the garbage can is greatly enhanced, and there is no need to wait for the entire 5 garbage cans to move up and down at the same time, which greatly ...

Embodiment 3

[0055] When collecting rubbish with the garbage sorting collection system of the present invention, when a certain kind of rubbish is too much to produce overflowing garbage, the garbage cans in Embodiments 1 and 2 cannot meet the requirements, and the garbage cans can be replaced by two garbage cans.

[0056] Such as Figure 5 As shown, the trash can includes two trash cans, one is a narrow and high small trash can 27, and the other is a wide and short large trash can 29, and the two trash cans are connected by a slideway 28 that expands. Excessive rubbish is directly imported in the large trash can 29 by slideway 28.

[0057] Such as Figure 5 As shown, the small trash can 27 and the large trash can 29 are suitable for lifting and lowering on the vertical slideway 1 simultaneously to complete the treatment of overflowing garbage.

[0058] Such as Figure 6 As shown, only the narrow and high small garbage can 27 is lifted, but the wide and short large garbage can 29 is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com