A duck meat flavor essence prepared by extrusion technology

A technology for essence and duck meat, applied in the field of duck meat flavor essence, can solve the problems of inconspicuous roasting flavor, insufficient duck meat flavor, inability to give full play to the flavor and aroma of duck meat flavor essence, etc. The effect of high and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

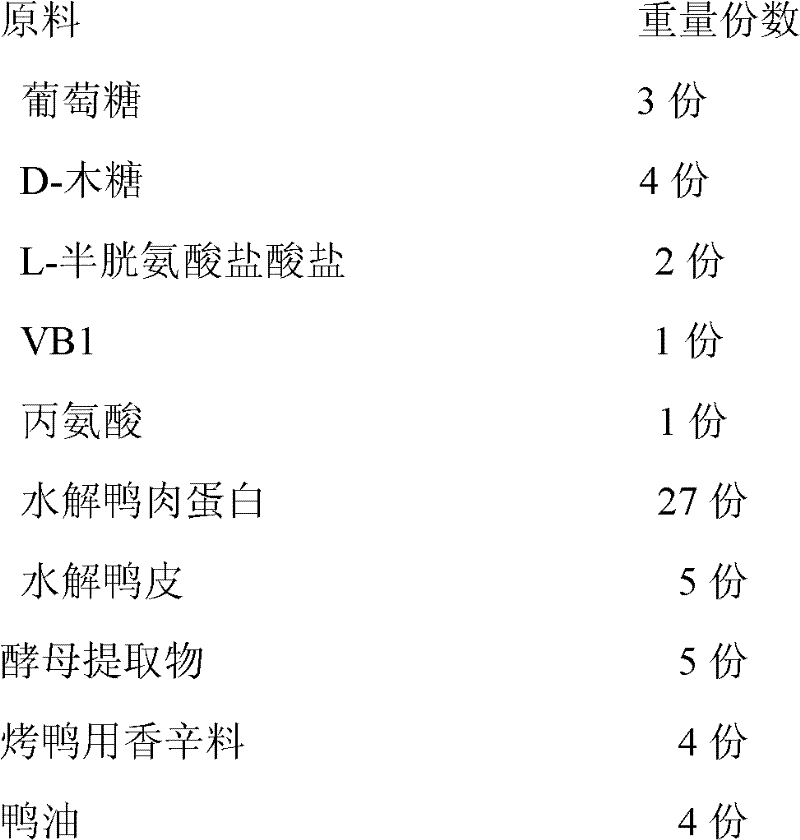

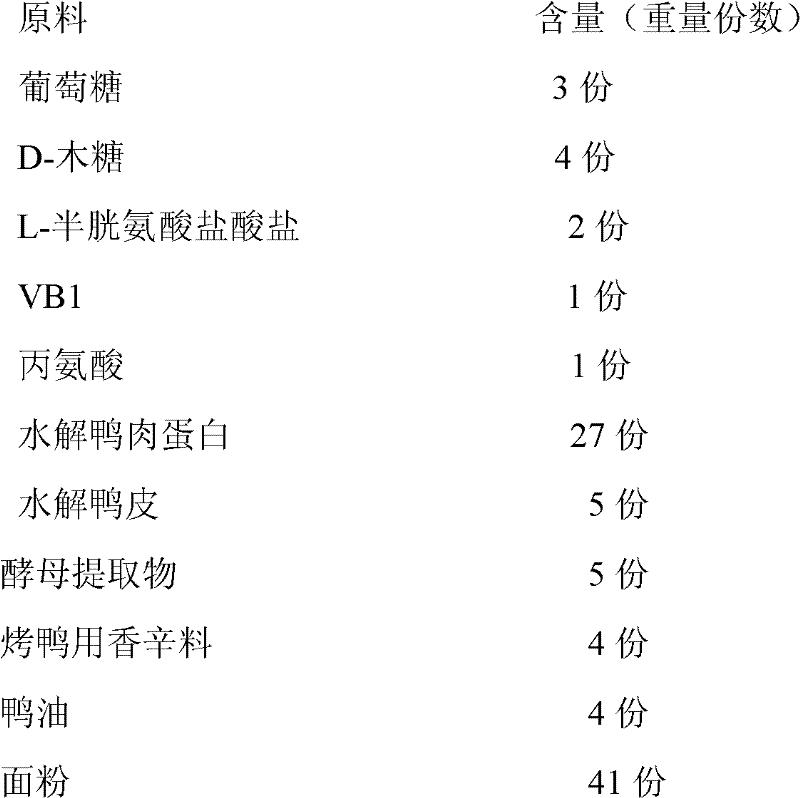

[0037] The formula for producing Beijing roast duck flavor essence by extrusion technology is as follows:

[0038]

[0039]

[0040] The components and mass percentages of the spices for roast duck are 40% of white pepper, 15% of anise, 10% of Angelica dahurica, 15% of green onion powder, 15% of ginger powder and 5% of nutmeg.

[0041] Add the raw materials into the mixer according to the formula and mix them evenly to obtain a raw material mixture. The measured moisture content is 11.7%. Preheat the twin-screw extruder to the specified temperature. The preset mixing zone temperature is 80°C and the shearing zone is 120°C. °C, the melting zone is 160 °C. The raw material mixture is added in the feed hopper of the twin-screw extruder, the extruder is started, and the screw speed is adjusted to be 155 rpm. The raw material mixture is transported from the hopper to the extruder at a speed of 63Kg / hour for extrusion, the extrusion reaction material extruded is cooled to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com