Composite steel bearing and manufacturing method

A technology of composite bearings and bearings, applied in the direction of bearings, bearing components, shafts and bearings, etc., which can solve the problems of unsatisfactory large bearings, deformation or wear or other harmful bearings, and failure to provide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

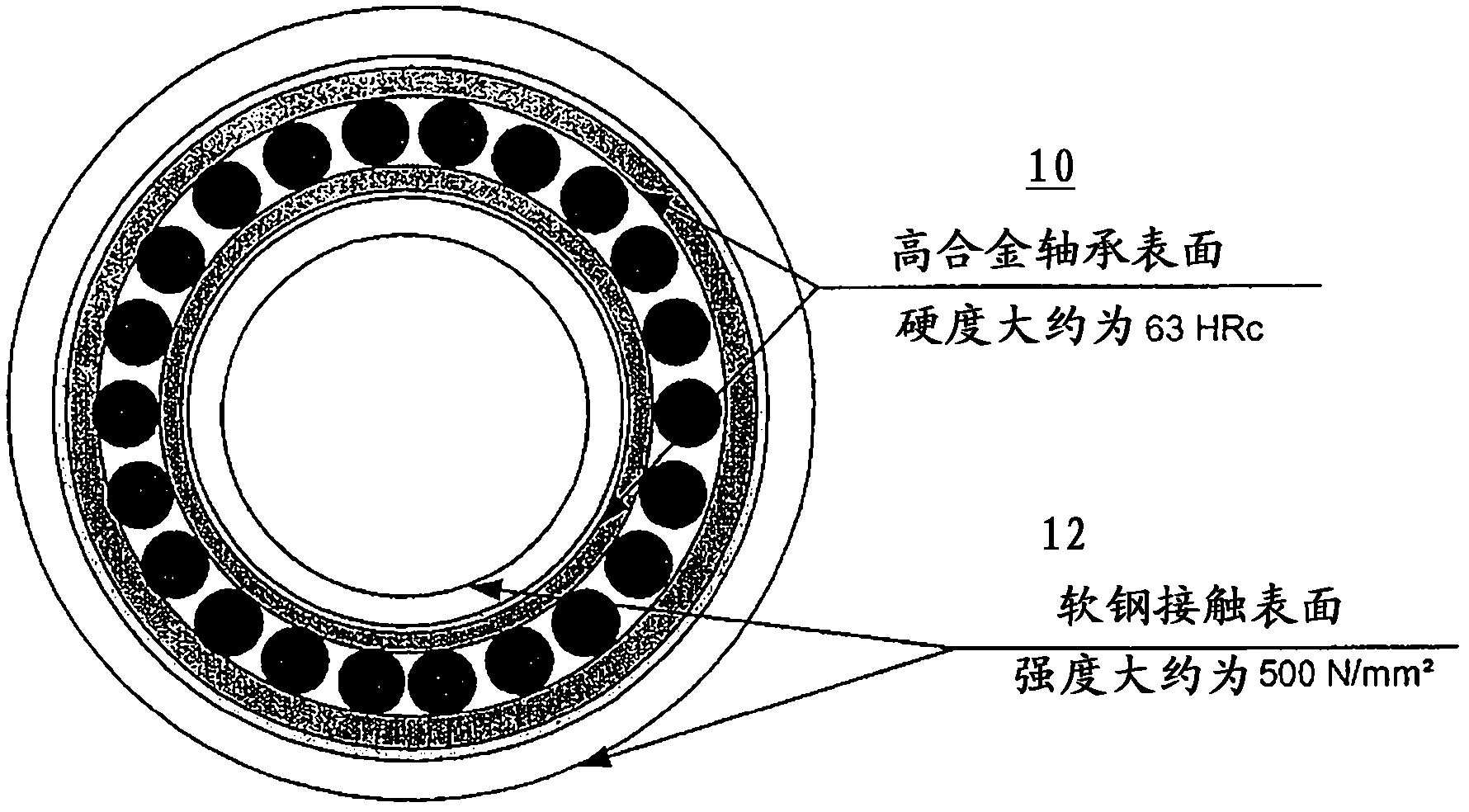

[0031] figure 1 A top plan view of a composite steel roller bearing according to the invention is shown. As described in detail herein, the roller bearing includes a high alloy bearing portion 10 and a mild steel bearing portion 12 .

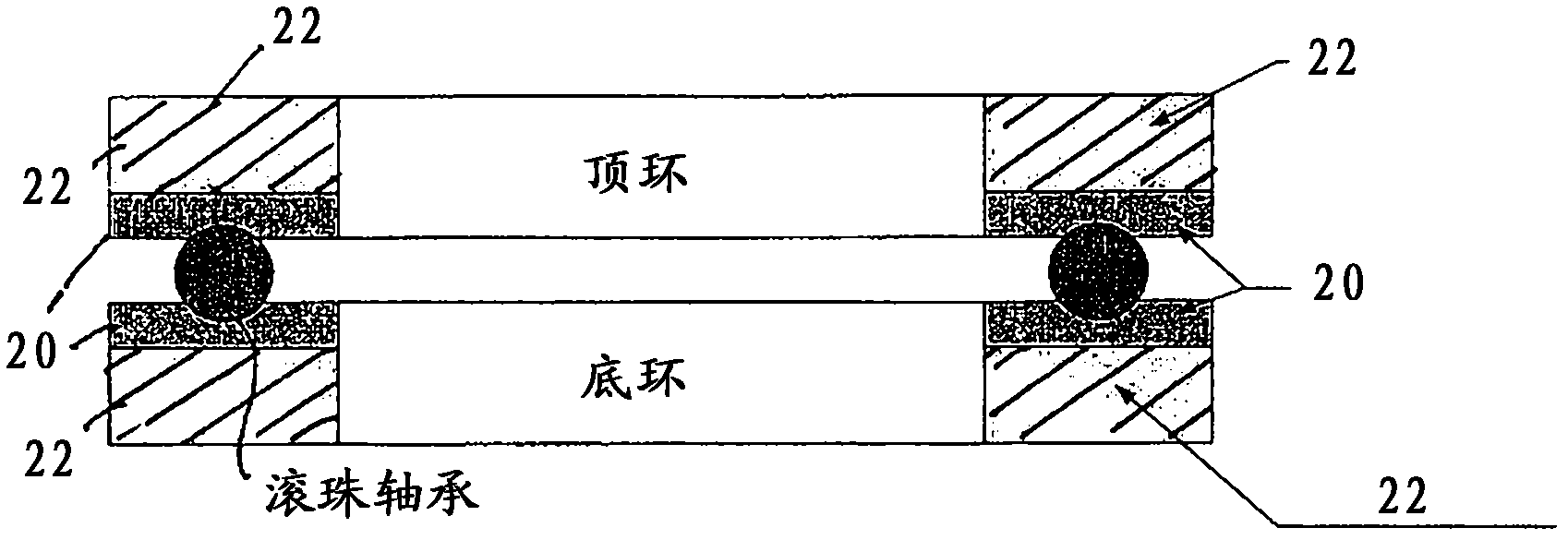

[0032] figure 2 A side view of a cross section taken through a ring bearing according to the invention is depicted. similar to figure 1 In the illustrated embodiment, the bearing includes a high alloy layer 20 and a mild steel layer 22 . Such annular bearings may be particularly suitable for use as azimuth bearings for wind turbines.

[0033] Such annular composite steel bearings are well suited for transmitting high axial forces and large bending moments with small relative movements between cooperating bearing components. Wind power installations may include such bearings between the head of a machine supported by its tower and the head of the tower, such as in Figure 15-Figure 16 in the public.

[0034] Bearings of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com