Double-sided gluing aluminum strip for composite pipe and preparation method of double-sided gluing aluminum strip

A technology of double-sided gluing and composite rolling, applied in chemical instruments and methods, applications, belts, etc., can solve the problems affecting the performance of composite pipes, poor bonding, poor strength, etc., to eliminate microscopic Defects in tissue, improved connectivity and integrity, effects of improved compression and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

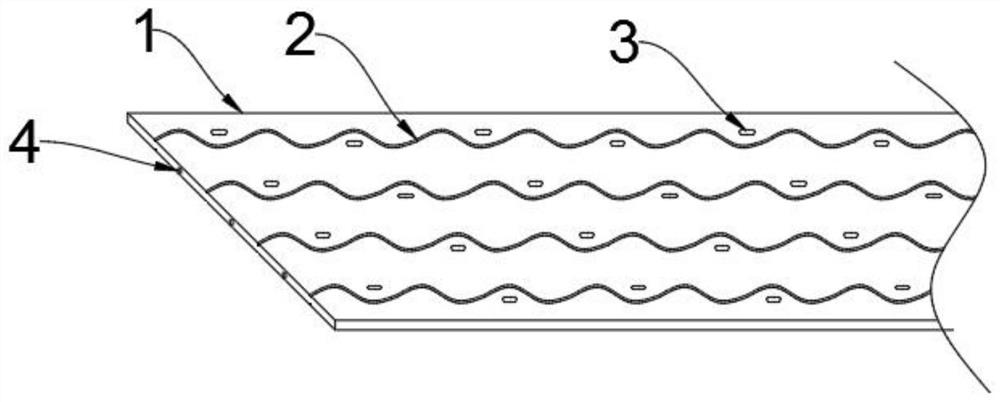

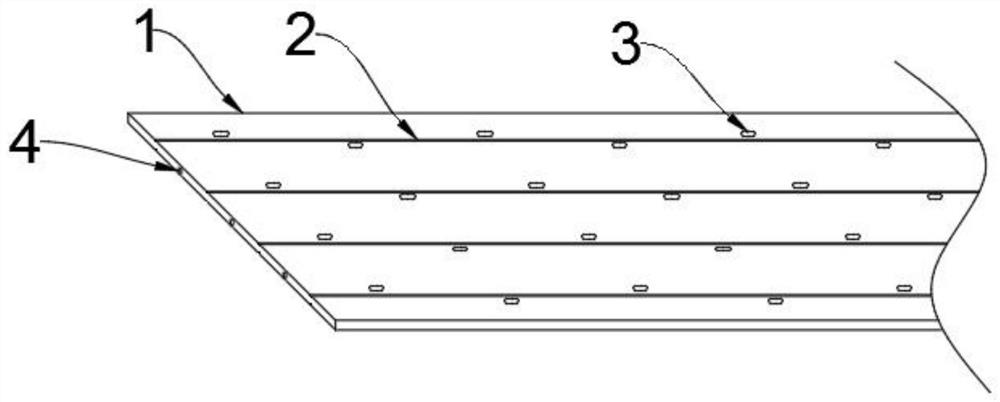

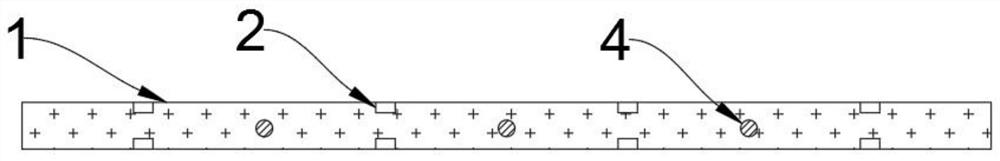

[0033] See Figure 1-3 An embodiment of the present invention provides: A composite double-sided adhesive aluminum pipe, comprising an aluminum strip, aluminum strip 1 above and below the recesses are symmetrically provided with an adhesive 2, and the adhesive 2 is provided with a recess there are four internal sides adhesive aluminum strip 1 along the groove 2 is provided with a through-hole 3, the aluminum strip 1 is attached to the inside steel wire 4, and the aluminum strip 14 is fixedly connected to the steel wire; wherein, aluminum preparation ingredients, in parts by weight, comprising the following components: Cu: 0.04-0.25%, zinc: 0.1-0.3%, Fe: 0.5-0.7%, Si: 0.4-0.7%, Mn: 1-1.5%, the balance being aluminum and other impurities, the adhesive 2 is provided a recess, can effectively increase the surface roughness of the aluminum strip 1, and to improve the fastness of the adhesion of the hybrid pipe, the through-hole 13 is provided aluminum, the aluminum may be increased 1 of...

Embodiment 2

[0051] See Figure 1-3 One embodiment of the present invention is provided in a composite tube, a double-sided coated aluminum strip, including an aluminum strip 1, and below the aluminum belt 1, respectively, a bonding groove 2 is provided, and the adhesive groove 2 is disposed. There are four, and the inside of the aluminum strip 1 is provided with through holes 3 along both sides of the adhesive groove 2, and the inside of the aluminum belt 1 is mounted, and the aluminum strip 1 is fixed to the steel wire 4; wherein the aluminum belt is Preparation ingredients, by weight, including the following components: copper: 0.04-0.25%, zinc: 0.1-0.3%, iron: 0.5-0.7%, silicon: 0.4-0.7%, manganese: 1-1.5%, The balance is aluminum and other impurities, the arrangement of the bonding groove 2 can effectively increase the roughness of the surface of the aluminum strip 1, improve the bonding firmness of the aluminum belt 1 and the composite tube, and the arrangement of the through hole 3 can i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com