Aquatic product conveyor

A technology for conveyors and aquatic products, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as interference, uneven transportation volume, insufficient material storage box ration, etc., to achieve processing cleanliness, guarantee stability, Improve the effect of flexible fine-tuning operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

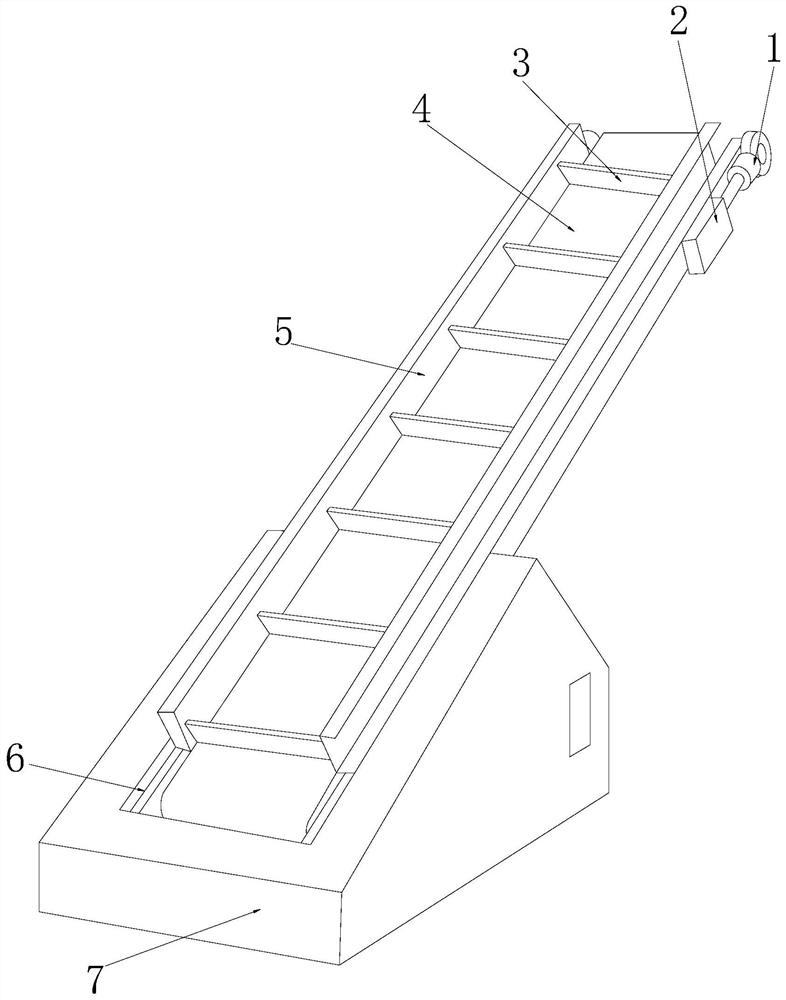

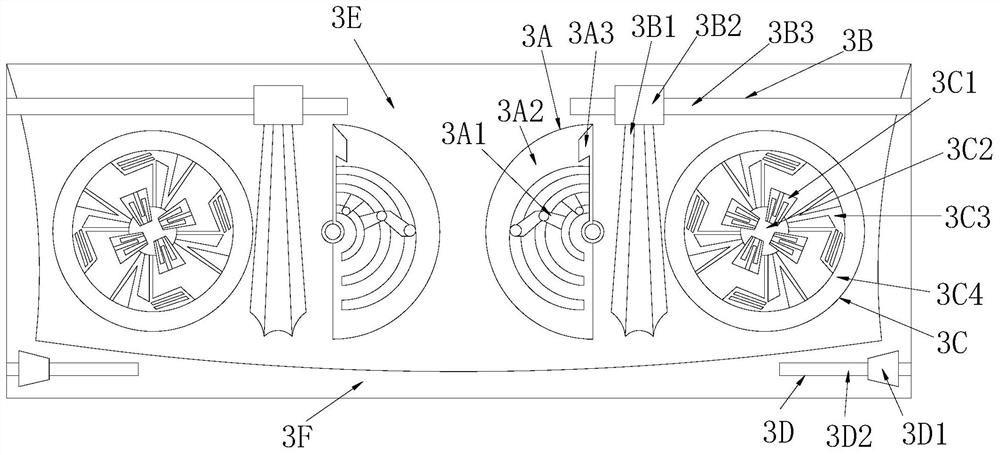

[0033] see Figure 1-Figure 6, the present invention provides a kind of aquatic products conveyor, its structure comprises: sling ring seat 1, hydraulic cylinder frame 2, colloidal rotary brush baffle 3, transmission belt 4, guide rail bar 5, concave frame 6, motor frame block 7. There are more than two colloidal rotary brush baffles 3 and they are all inserted and embedded on the top surface of the transmission belt 4. The guide rail bars 5 and the transmission belt 4 adopt clearance fit, and the concave frame 6 and the motor The frame blocks 7 are snapped together and are on the same slope, the concave frame 6 is nested under the bottom of the conveyor belt 4 and are on the same slope, and the sling ring seat 1 is nested on the top of the hydraulic cylinder frame 2 and the axes are on the same line, the hydraulic cylinder frame 2 is installed on the upper right corner of the conveyor belt 4 and is on the same slope, the guide rail bar 5 is fastened with the concave frame 6, ...

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides a kind of aquatic products conveyor, other respects are identical with embodiment 1, and difference is:

[0041] see figure 2 , the clamping slider bar 3D is composed of a trapezoidal beam tube 3D1 and a short rail bar 3D2, the trapezoidal beam tube 3D1 is mechanically connected with the short rail bar 3D2 and the axes are collinear, and the short rail bar 3D2 is installed on the trapezoidal beam bar 3D2 The inside of the shaft center of the cylinder 3D1 passes the trapezoidal beam cylinder 3D1 roller subcontract and presses the short rail rod 3D2 to slide laterally, so as to ensure the convenient tripping operation of the output of the kelp at the bottom.

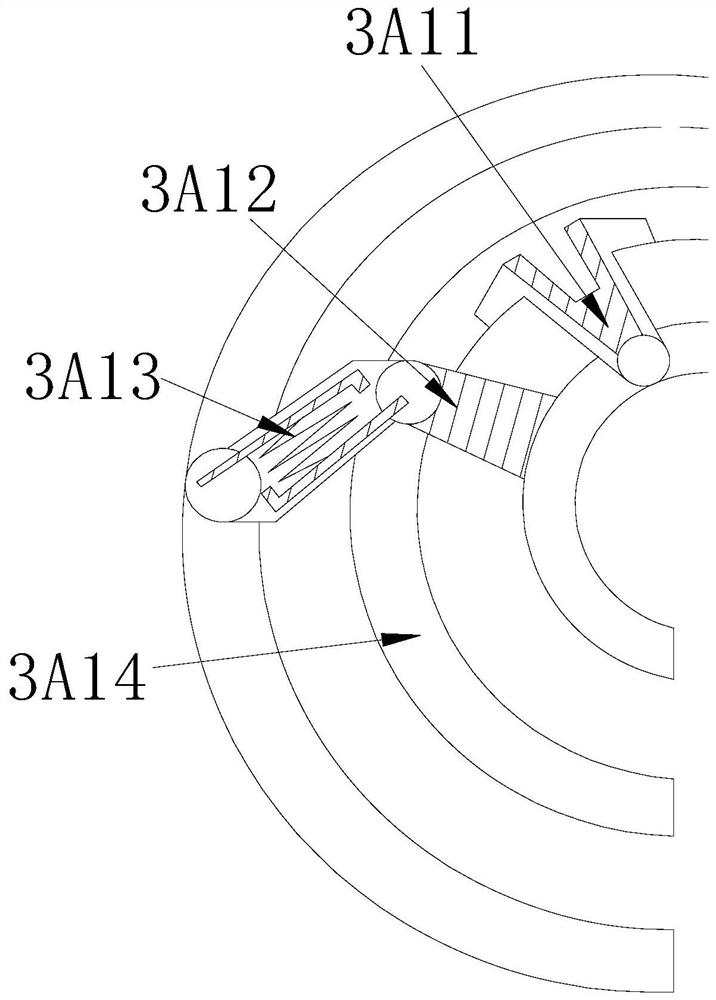

[0042] see Figure 6 , the trapezoidal beam tube 3D1 is composed of an oblique hanging wheel rod seat 3D11, a folding frame rod 3D12, a curved petal beam tube 3D13, and a bow rib 3D14, and the oblique hanging wheel rod seat 3D11 is fastened with the folding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com