Automatic slag powder adding device of continuous casting machine crystallizer

A crystallizer and continuous casting machine technology, which is applied in the field of slag adding devices, can solve the problems of large volume, inconvenient operation, and mold slag damage of the mold slag adding device, and achieve compact structure, convenient disassembly and assembly, and guaranteed mobility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

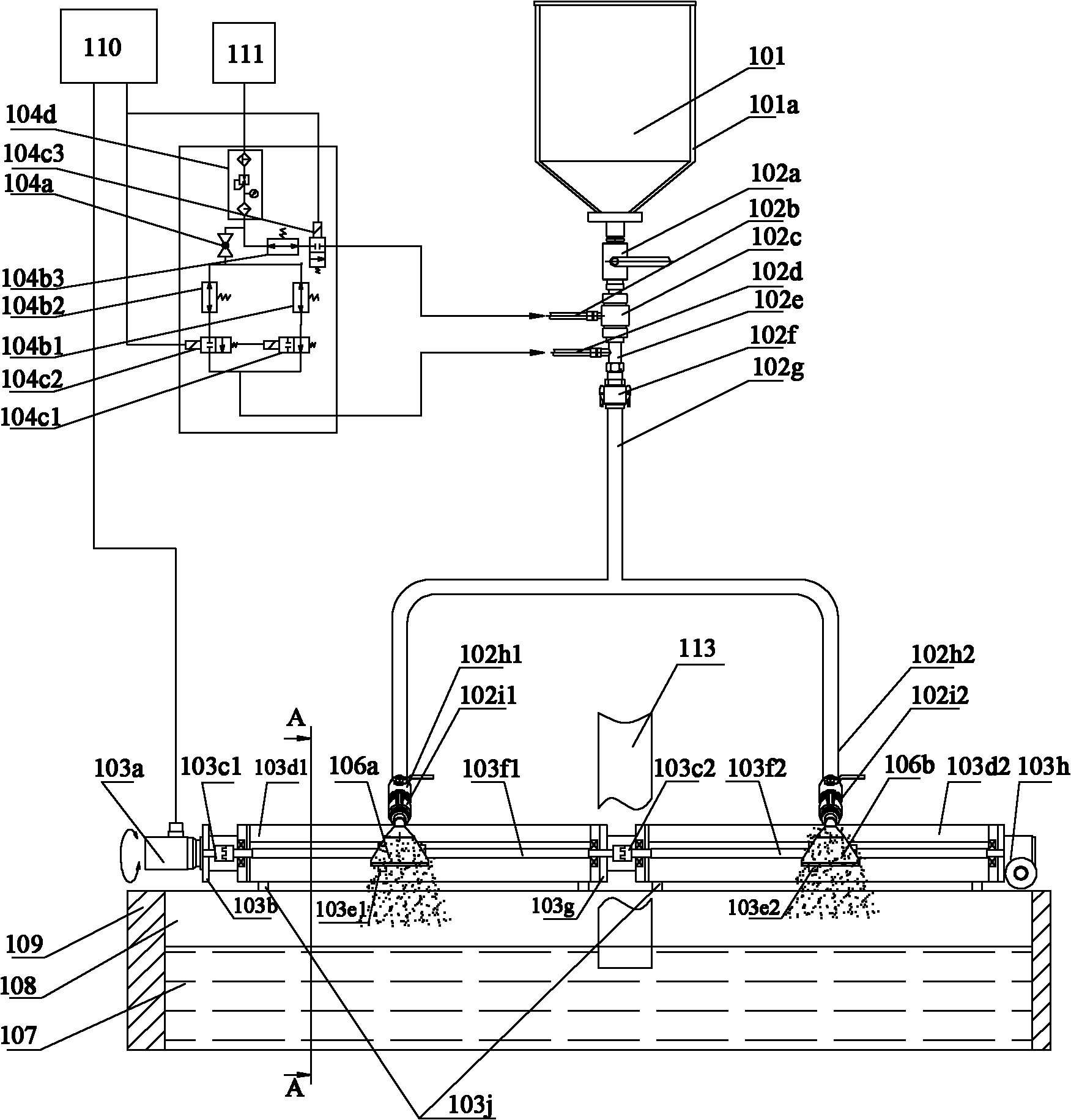

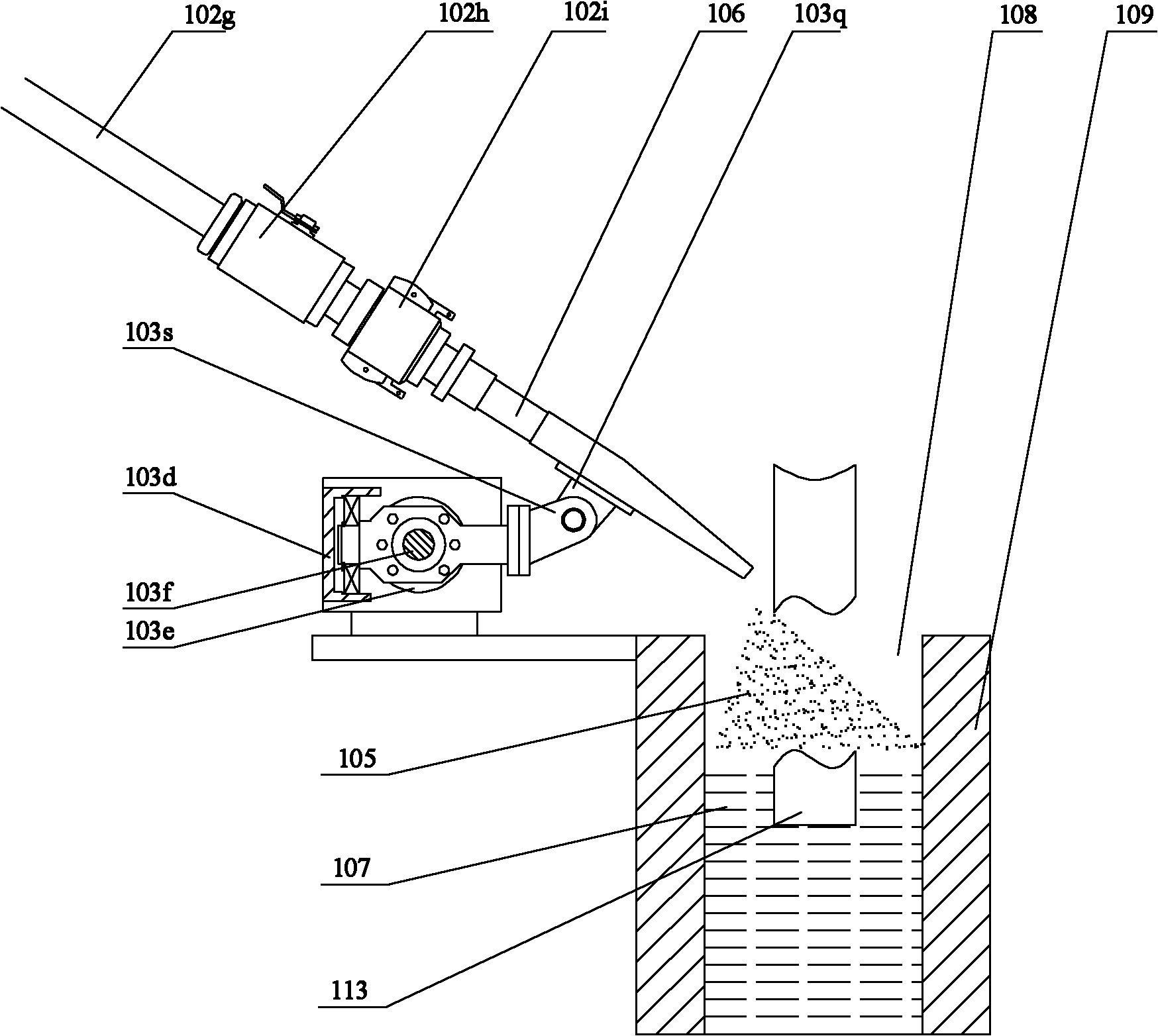

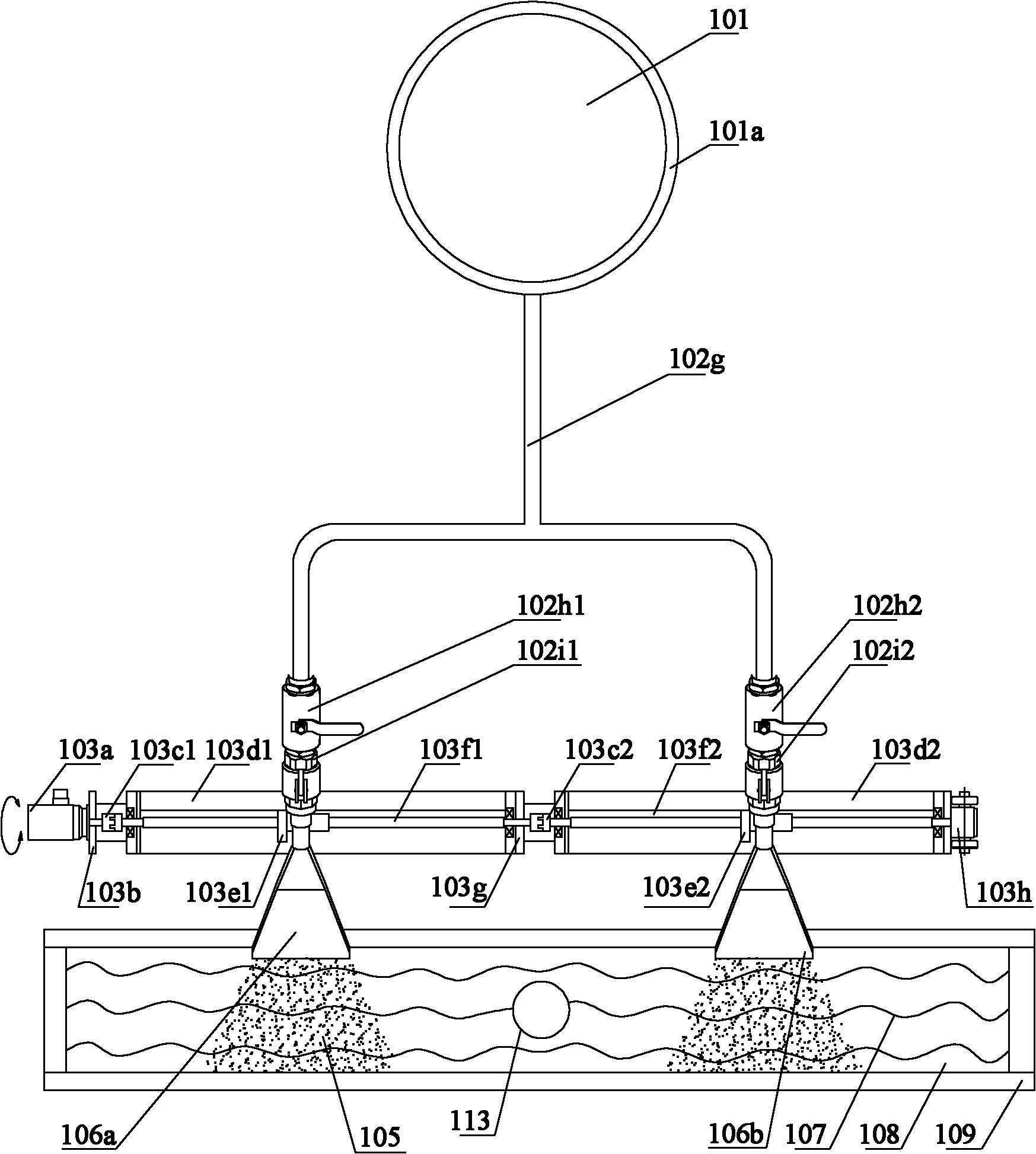

[0035] The present invention provides a device for automatically adding mold slag to the crystallizer of a continuous casting machine, as a preferred embodiment, combined with figure 1 , figure 2 and image 3 , to describe the structure of the automatic powder slag adding device.

[0036] The device for automatically adding mold slag to the mold of a continuous casting machine provided by the present invention can be applied to the mold 109 of a slab continuous casting machine. The heating device 101a with a double-layer drum structure is used for dehumidifying mold slag.

[0037] In order to realize that the slag adding nozzle can automatically and evenly spread mold slag on the mouth of the crystallizer, the automatic mold slag adding device p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com