Method for welding steel plate by multi-layer welding

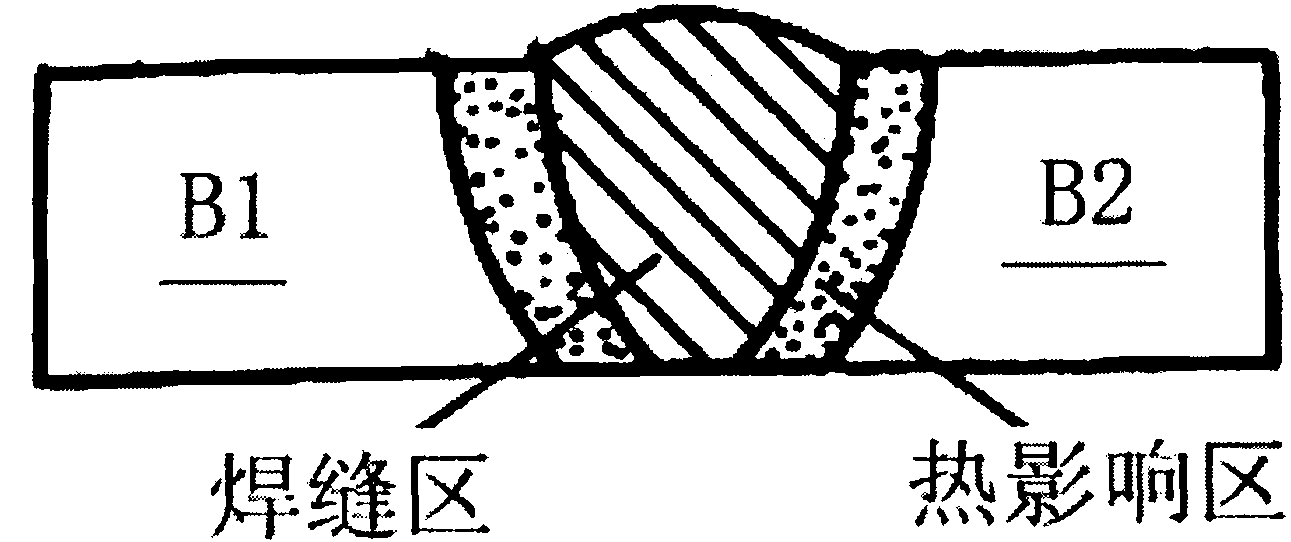

A technology for welding steel plates and multi-layer welding, which can be used in welding media, welding equipment, welding equipment, etc., and can solve problems such as insufficient mechanical properties of welded joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

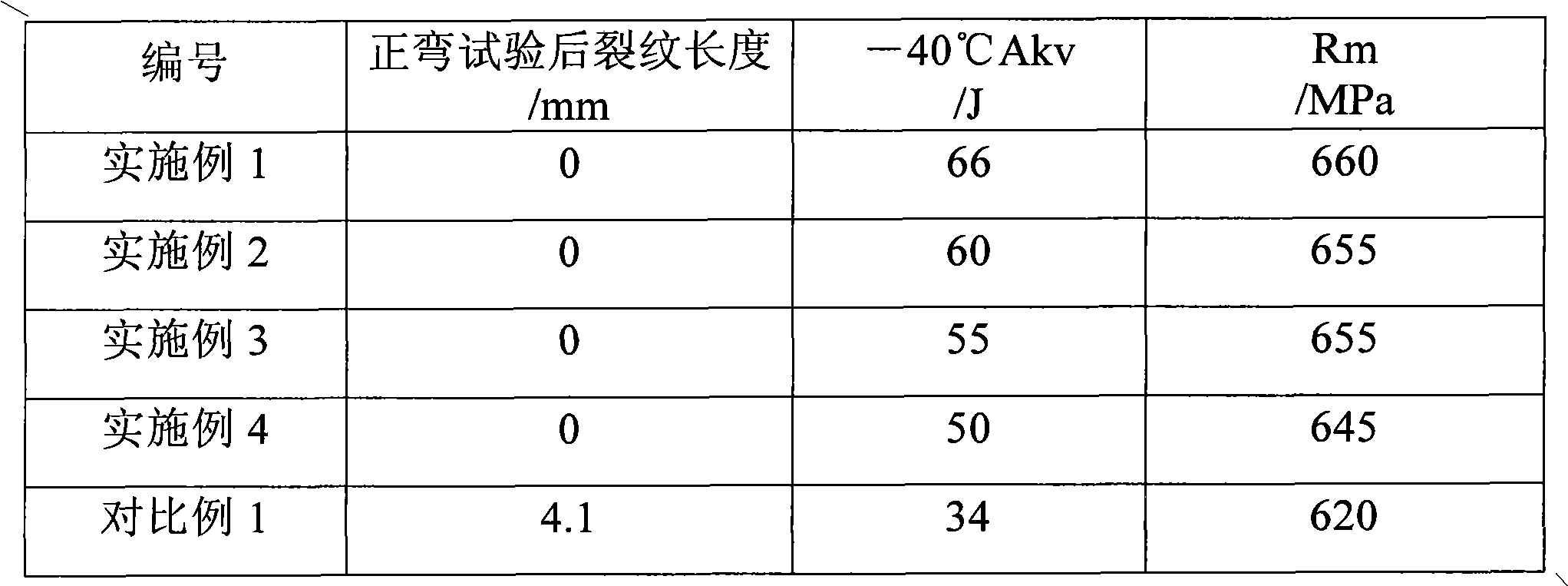

Examples

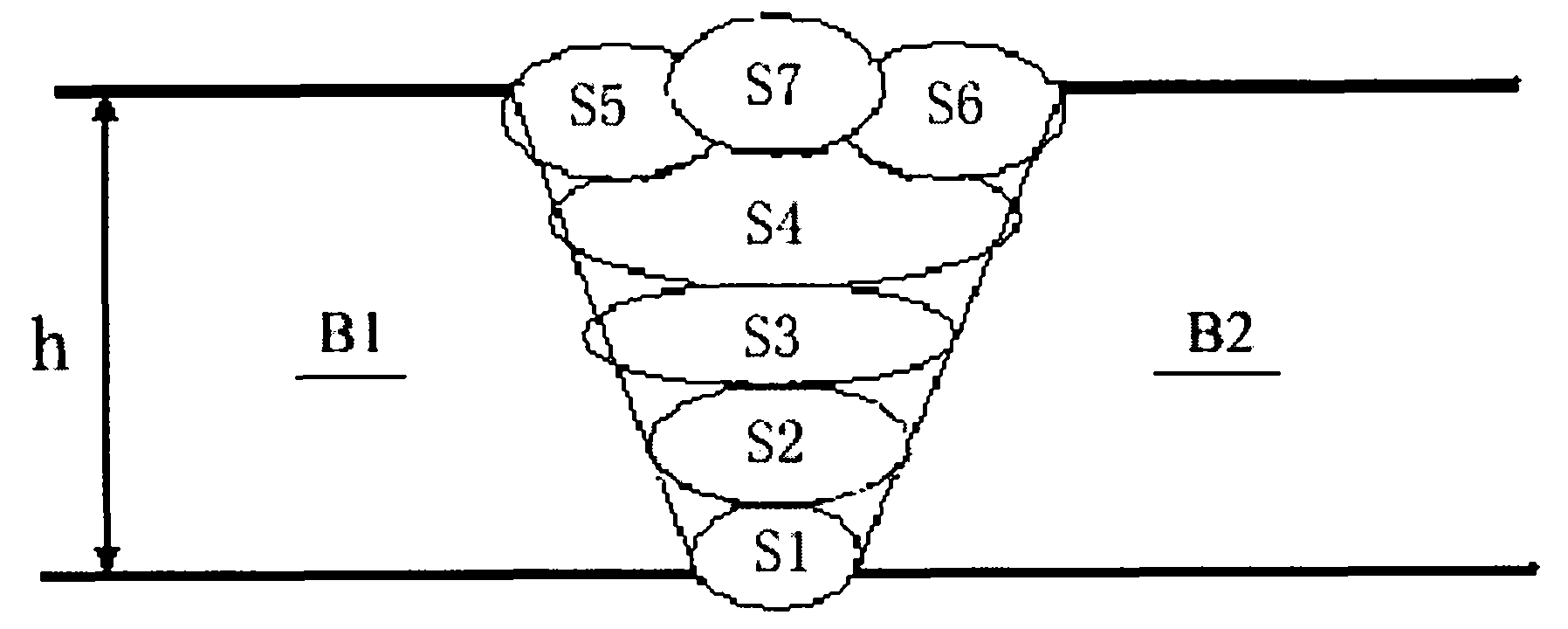

Embodiment 1

[0034] use figure 2 The multilayer welding process shown uses MAG welding to perform multilayer welding of Q450NQR1 steel plates with a thickness of 12mm. The shielding gas for MAG welding is Ar80%+20%CO 2 (volume fraction); the steel plate has a V-shaped groove; it is welded by one-sided welding and double-sided forming. The alloy composition of Q450NQR1 steel plate is shown in Table 1 (the content unit of each alloy element is weight %); S1-S7 uses the same welding material TH550-NQ-A, and the composition (mass %) is C 0.06, Si 0.37, Mn 1.30 , P 0.014, S 0.009, Cu 0.34, Cr 0.34, Ni 0.52, welding wire specification Φ1.2mm; the process parameters of MAG welding and the thickness of deposited metal in each pass are shown in Table 2. Among them, the interlayer temperature of S1-S6 welding is 100°C, and the interlayer temperature of S7 welding is 180°C. The groove angle of the V-shaped groove of two Q450NQR1 steel plates is 45°, and the pairing gap is 2.2mm.

[0035] Table 1 ...

Embodiment 2

[0041] The Q450NQR1 steel plate with a thickness of 12mm is welded according to the method of Example 1. The difference is that the alloy composition of the Q450NQR1 steel plate used is shown in Table 1, and the process parameters of MAG welding and the thickness of the deposited metal in each pass are shown in Table 3. It shows that the interlayer temperature of S1-S6 is 120°C, and the interlayer temperature of S7 welding is 190°C.

[0042] table 3

[0043] pass

Embodiment 3

[0045] The Q450NQR1 steel plate with a thickness of 12mm is welded according to the method of Example 2. The difference is that the alloy composition of the Q450NQR1 steel plate used is shown in Table 1, and the process parameters of MAG welding and the thickness of the deposited metal in each pass are shown in Table 4. It shows that the interlayer temperature of S1-S6 is 150°C, the interlayer temperature of S7 welding is 200°C, and the groove angle of the V-shaped groove of two Q450NQR1 steel plates is 60°.

[0046] Table 4

[0047] pass

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com