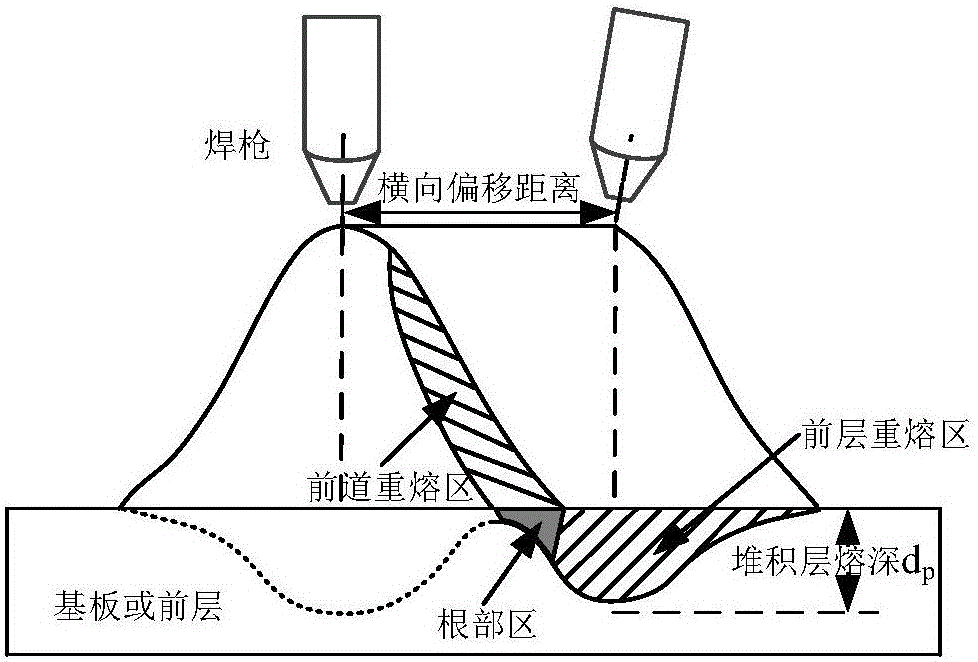

Fusion penetration method for arc wire filling additive manufacturing root zone of thick-wall structural element

A technology of additive manufacturing and wall structure, applied in the direction of manufacturing tools, arc welding equipment, electrode support devices, etc., can solve the problems of small melting area and low metallurgical bonding strength between layers, so as to avoid excessive remelting and eliminate hole defects , to achieve the effect of effective use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

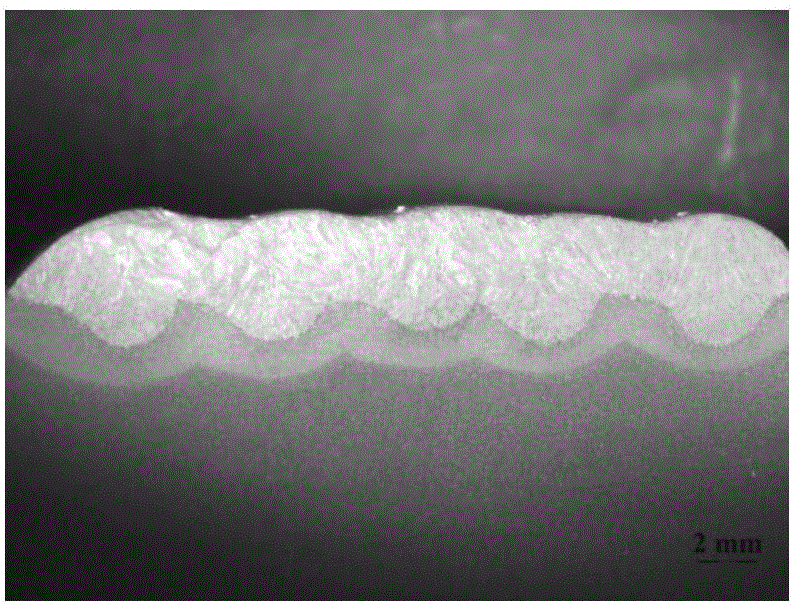

Embodiment 1

[0051] The thick-walled structural part formed in this embodiment has a structure of 20 layers and 5 layers, that is, the number of forming layers is 20 layers, 5 layers are formed on each layer, the forming path is a straight line, and the forming length of each layer is 150 mm. The arc-filling additive manufacturing test platform is: the arc additive manufacturing power supply is the gas-shielded Fronius TPS4000 welding machine, the gas-shielded welding torch is installed on the end of the sixth axis of the ABB six-axis robot, and the movement and posture of the welding torch are controlled by the robot Adjustment. Additive manufacturing process parameters are: forming current 150A, arc voltage 20V, welding torch walking speed 5mm / s, forming shielding gas 95% Ar+5% CO 2 , the gas flow rate is 18L / min, the filler wire is H08Mn2Si low-carbon steel wire, the wire diameter is 1.2mm, the substrate is Q235 low-carbon steel plate, and the substrate size is 200mm×150mm×10mm.

[005...

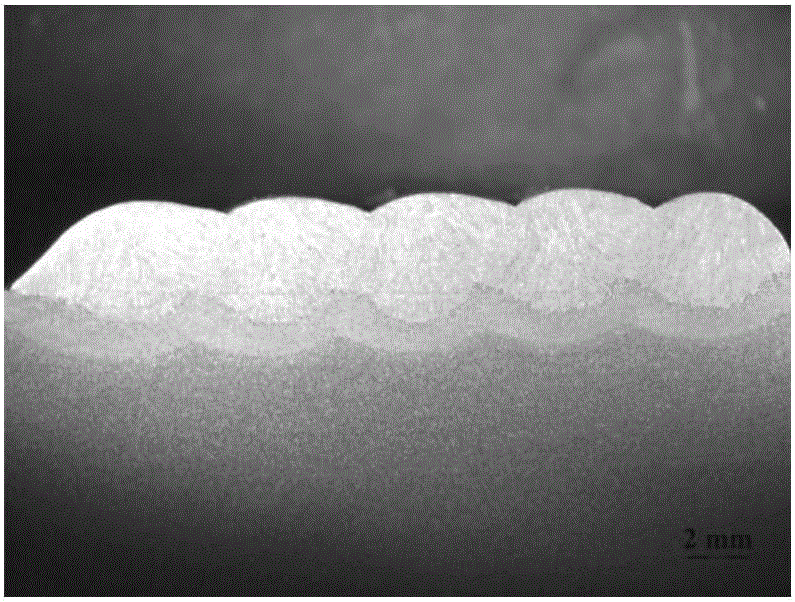

Embodiment 2

[0060] The thick-walled structural part formed in this embodiment has a structure of 30 layers and 3 layers, that is, the number of forming layers is 30 layers, 3 layers are formed on each layer, the forming path is a straight line, and the forming length of each layer is 160 mm. The arc-filling additive manufacturing test platform is: the arc additive manufacturing power supply is a MagicWave 3000 welding machine, the argon tungsten arc welding torch is installed on the end of the sixth axis of the ABB six-axis robot, and the movement and attitude adjustment of the welding torch are controlled by the robot. Additive manufacturing process parameters are: forming current 110A, arc voltage 19V, welding torch walking speed 3mm / s, wire feeding speed 0.8m / min, forming shielding gas 95% Ar+5% CO 2 , the gas flow rate is 18L / min, the filler wire is H08Mn2Si low-carbon steel wire, the wire diameter is 1.2mm, the substrate is Q235 low-carbon steel plate, and the substrate size is 200mm×...

Embodiment 3

[0067] The thick-walled structural part formed in this embodiment has a structure of 25 layers and 8 layers, that is, the number of forming layers is 25 layers, 8 layers are formed on each layer, the forming path is a closed ring, and the circumference length of each layer is 200mm. The arc-filling additive manufacturing test platform is: the arc additive manufacturing power supply is the gas-shielded Fronius TPS4000 welding machine, the gas-shielded welding torch is installed on the end of the sixth axis of the ABB six-axis robot, and the movement and posture of the welding torch are controlled by the robot Adjustment. The process parameters of additive manufacturing are: forming current 260A, arc voltage 26V, welding torch walking speed 12mm / s, forming shielding gas 95% Ar+5% CO 2 , the gas flow rate is 18L / min, the filler wire is H08Mn2Si low-carbon steel wire, the wire diameter is 1.2mm, the substrate is Q235 low-carbon steel plate, and the substrate size is 200mm×150mm×10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com