Method for growth of oversized crystal with the photo-magnetic function of rare earth orthoferrite

A technology of orthoferrite and crystal growth, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as less crystallization amount of melt, small crystal size, complex phase relationship, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

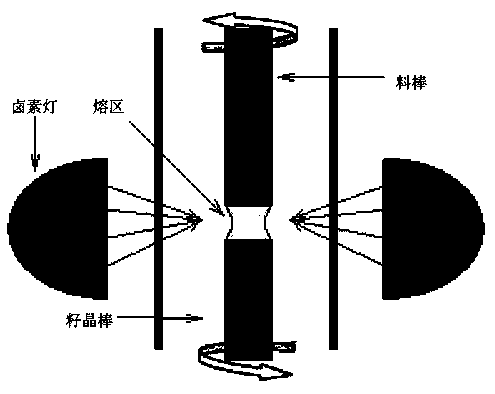

Method used

Image

Examples

Embodiment

[0019] SM 0.5 Tb 0.5 FeO 3 The specific steps of single crystal preparation are as follows:

[0020] A. Preparation of polycrystalline rods

[0021] d) The initial raw material is high-purity (above 3N) R 2 o 3 (R=Sm, Tb), Pr 6 o 11 and Fe 2 o 3 ; will Sm 2 o 3 , Tb 2 o 3 with Fe 2 o 3 Prepare Sm at a molar ratio of 1:1:2 0.5 Tb 0.5 FeO 3 Rod as stock; and Pr 6 o 11 and Fe 2 o 3 Preparation of PrFeO with a molar ratio of 1:3 3 As a seed crystal, it is cast into a rod; accurately weighed, ground, and fully mixed according to the above-mentioned composition ratio; placed in a high-temperature furnace and sintered in air at a temperature of 1000 ° C for 12 hours, and naturally dropped to room temperature with the furnace;

[0022] e) Grind the pre-sintered raw materials with an agate mortar, put the polycrystalline material into a mold, and press isostatically under a pressure of 50-200 MPa to prepare PrFeO with a diameter of 6-8 mm and a length of about 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com