Preparation method of nickel oxide/carbon sphere composite material

A technology of composite materials and carbon spheres, applied in nanotechnology for materials and surface science, hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problems of unsatisfactory actual performance, low working voltage, and poor conductivity and other issues, to achieve high specific capacitance value, improve conductivity, and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Alkali treatment of ordered mesoporous carbon spheres: Add 0.1 g of mesoporous carbon spheres into a round-bottomed flask filled with 50 mL of 6M NaOH solution, stir on a magnetic stirrer for 10 minutes, and then ultrasonically disperse for 20 minutes to make The carbon spheres are uniformly dispersed in the solution. Magnetic stirring and reflux at 150°C for 24 hours, then naturally cool to room temperature; then the reaction system was centrifuged to obtain a precipitate, and then the obtained precipitate was centrifugally washed several times with deionized water and ethanol as the washing liquid, and then the obtained precipitate was vacuum-washed Dry to obtain alkali-treated carbon pellets.

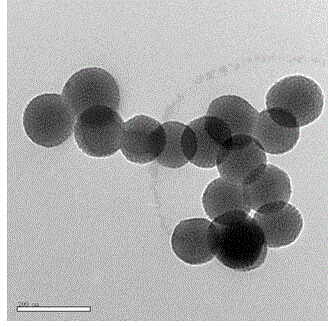

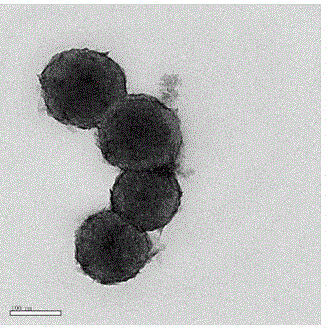

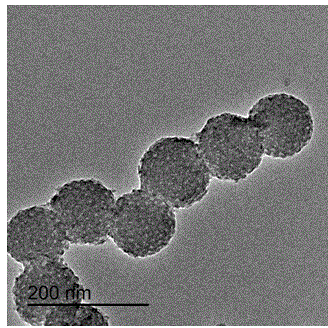

[0035] Carrier carbon pellets such as figure 1 shown. From figure 1 It can be seen that the ordered mesoporous carbon spheres present uniform nano-spherical morphology, regular and ordered pore structure, and good monodispersity.

[0036] 2. Preparation of nickel hydrox...

Embodiment 2

[0041] 1. Alkali treatment of ordered mesoporous carbon spheres: Add 0.1 g of mesoporous carbon spheres into a round-bottomed flask filled with 50 mL of 6 M NaOH solution, stir on a magnetic stirrer for 10 minutes, and then ultrasonically disperse for 20 minutes. The carbon pellets are evenly dispersed in the solution. Magnetic stirring and reflux at 150°C for 24 hours, and then naturally cool to room temperature; then the reaction system was centrifuged to obtain a precipitate, and then deionized water and ethanol were used as washing liquids for centrifugal washing several times, and the obtained precipitate was vacuum-dried to obtain alkali treatment carbon pellets.

[0042] Carrier carbon pellets such as figure 1 shown. From figure 1 It can be seen that the ordered mesoporous carbon spheres present uniform nano-spherical morphology, regular and ordered pore structure, and good monodispersity.

[0043] 2. Preparation of nickel hydroxide / carbon pellet composite material ...

Embodiment 3

[0048] 1. Alkali treatment of ordered mesoporous carbon spheres: Add 0.1 g of mesoporous carbon spheres into a round-bottomed flask filled with 50 mL of 6M NaOH solution, stir on a magnetic stirrer for 10 minutes, and then ultrasonically disperse for 20 minutes to make The carbon spheres are uniformly dispersed in the solution. Magnetic stirring and reflux at 150°C for 24 hours, and then naturally cool to room temperature; then the reaction system was centrifuged to obtain a precipitate, and then deionized water and ethanol were used as washing liquids for centrifugal washing several times, and the obtained precipitate was vacuum-dried to obtain alkali treatment carbon pellets.

[0049] Carrier carbon pellets such as figure 1 shown. From figure 1 It can be seen that the ordered mesoporous carbon spheres present uniform nano-spherical morphology, regular and ordered pore structure, and good monodispersity.

[0050] 2. Preparation of nickel hydroxide / carbon pellet composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com