Preparation method of cellulose circular polarization thin film and cellulose linear polarization thin film and thin film products thereof

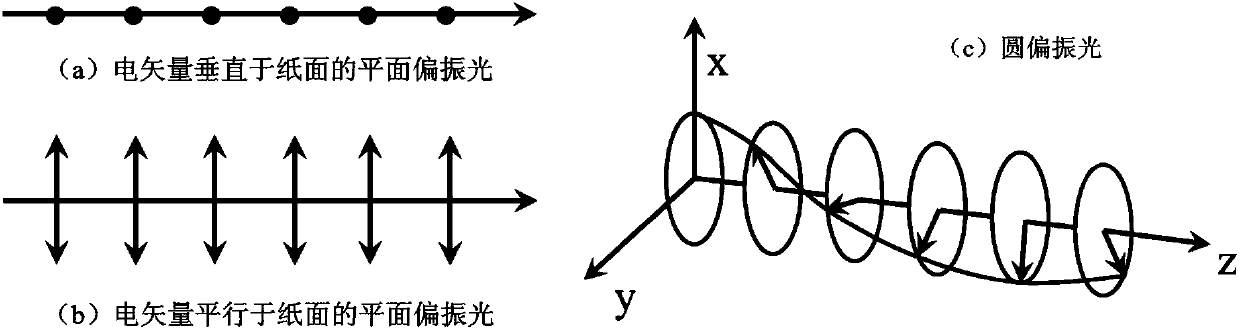

A cellulose and circular polarizing technology, which is applied in the preparation of cellulose circular and linear polarizing films and their products, can solve the problems of many influencing factors and complicated conditions for the formation of cholesteric liquid crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Take 1g of sea squirt cellulose, mix it with 17.5ml of 64% concentrated sulfuric acid, heat it in an oil bath at 45°C with a collector type constant temperature heating magnetic stirrer, and stir for 10h.

[0022] (2) Add 500ml of deionized water to dilute and cool down to terminate the reaction. Use a centrifuge to remove the supernatant, add deionized water, wash and then centrifuge at a speed of 8000-12000rad / min, and repeat the operation until the upper layer becomes cloudy.

[0023] (3) Put the suspension into a dialysis bag and dialyze with deionized water until the external solution becomes neutral, then put the dialysis bag into 15% polyethylene glycol (PEG) to concentrate to the required concentration.

[0024] (4) The obtained milky white suspension was ultrasonically treated with an ultrasonic cell pulverizer in an ice-water bath with a power of 800W for 30 minutes (wherein the ultrasonic frequency was 1 second on and 1 second off).

[0025] (5) Prepare a...

Embodiment 2

[0028] In step (1), ascidian cellulose can be pretreated by chemical methods such as dimethyl sulfoxide (DMSO), ethylenediamine, and sodium hydroxide, and physical methods such as high temperature and steam explosion, so as to weaken the hydrogen bond and shorten the hydrolysis time. All the other steps are the same as in Example 1.

Embodiment 3

[0030] In step (2), large particles can be removed at a speed of 2000rpm, and then the supernatant liquid can be washed and centrifuged. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com