Anti-shedding carbon nano paint and preparation method thereof

A nano-coating and anti-decarburization technology, used in polyether coatings, coatings, etc., can solve problems such as increased process energy consumption, unstable product quality, and inability to accurately control particle size distribution, achieving strong natural peeling ability, formulation And the coating process is simple and easy, and the effect of preventing high temperature oxidation and decarburization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

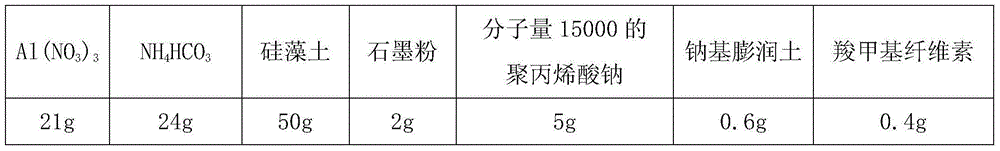

[0028] The quality of each chemical composition of the anti-decarburization nano-coating is as shown in Table 1:

[0029] Table 1 embodiment 1 prepares the raw material of coating and proportioning

[0030]

[0031] Weigh Al(NO 3 ) 3 and NH 4 HCO 3 were dissolved in deionized water to form solutions. Add refined diatomaceous earth to NH 4 HCO 3 Stir the solution into a suspension, and slowly add Al(NO 3 ) 3 solution for a precipitation reaction. Filter and wash the resulting precipitate and heat it at 200-300°C for 30 minutes to obtain nano-Al 2 o 3 and diatomaceous earth mixture. Sodium polyacrylate is first pre-dissolved in alcohol, then water is added to form a liquid binder. Add solvent, graphite powder, binder and suspending dispersant to this mixture, and then form nano decarburization prevention slurry after stirring evenly.

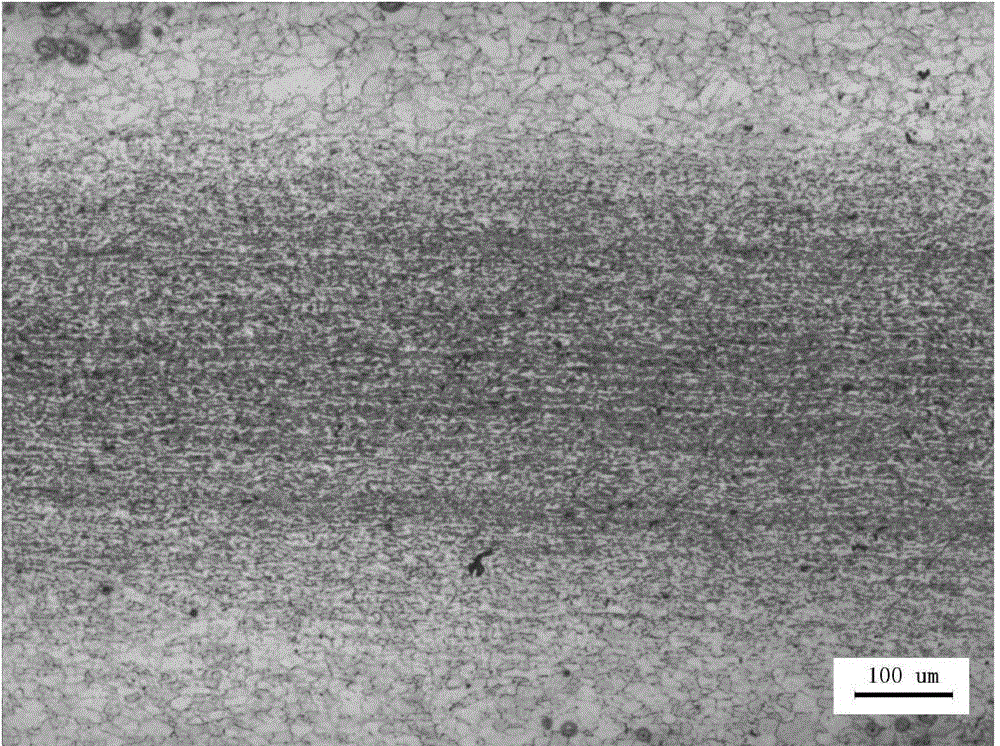

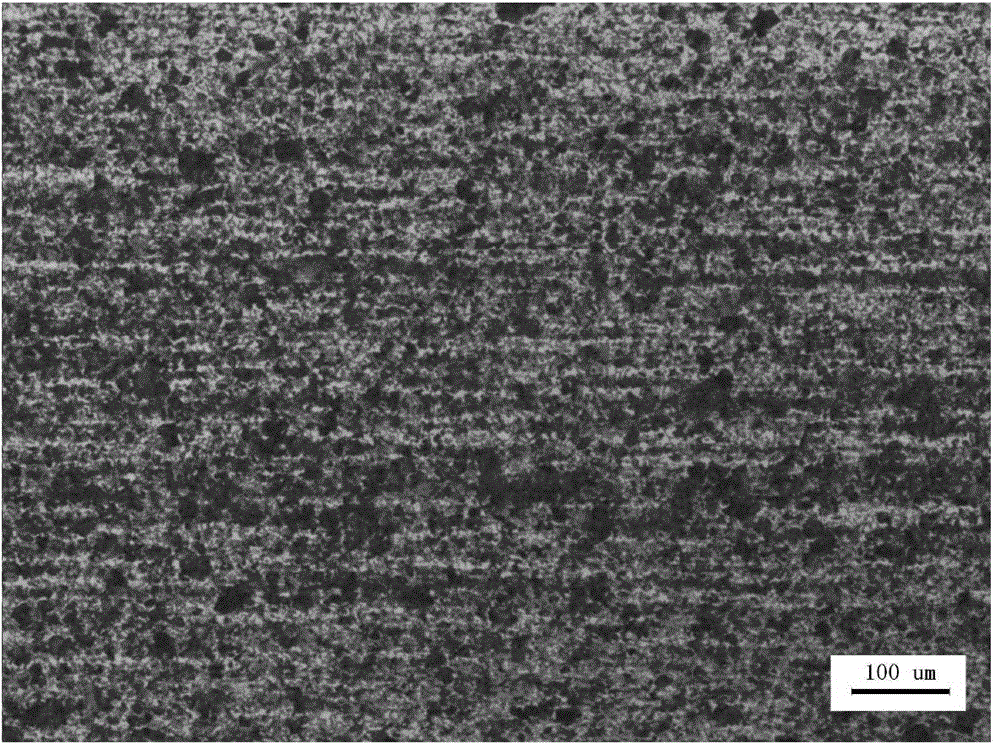

[0032] The prepared coating was uniformly sprayed on the surface of the 42CrMo sample to be heat treated at room temperature. Af...

Embodiment 2

[0034] The quality of each chemical composition of the anti-decarburization nano-coating is as shown in Table 2:

[0035] Table 2 Embodiment 2 coating composition distribution ratio

[0036]

[0037] Weigh Al(NO 3 ) 3 and NH 4 HCO 3 were dissolved in deionized water to form saturated solutions. Add diatomaceous earth to NH 4 HCO 3 Stir the solution into a suspension, and slowly add Al(NO 3 ) 3 solution for a precipitation reaction. Filter and wash the resulting precipitate and heat it at 200-300°C for 30 minutes to obtain nano-Al 2 o 3 and diatomaceous earth mixture. Sodium polyacrylate is first pre-dissolved in alcohol, then water is added to form a liquid binder. Add solvent, graphite powder, binder and suspending dispersant to this mixture, and then form nano decarburization prevention slurry after stirring evenly.

[0038]The prepared coating was evenly sprayed on the surface of the 30CrMoA sample to be heat treated at room temperature. After the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com