Sine waveform device for preparing semi-solid metal slurry

A semi-solid metal, sine wave technology, used in equipment that feeds molten metal into molds, metal processing equipment, manufacturing tools, etc. The effect of preventing the adhesion of crusts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

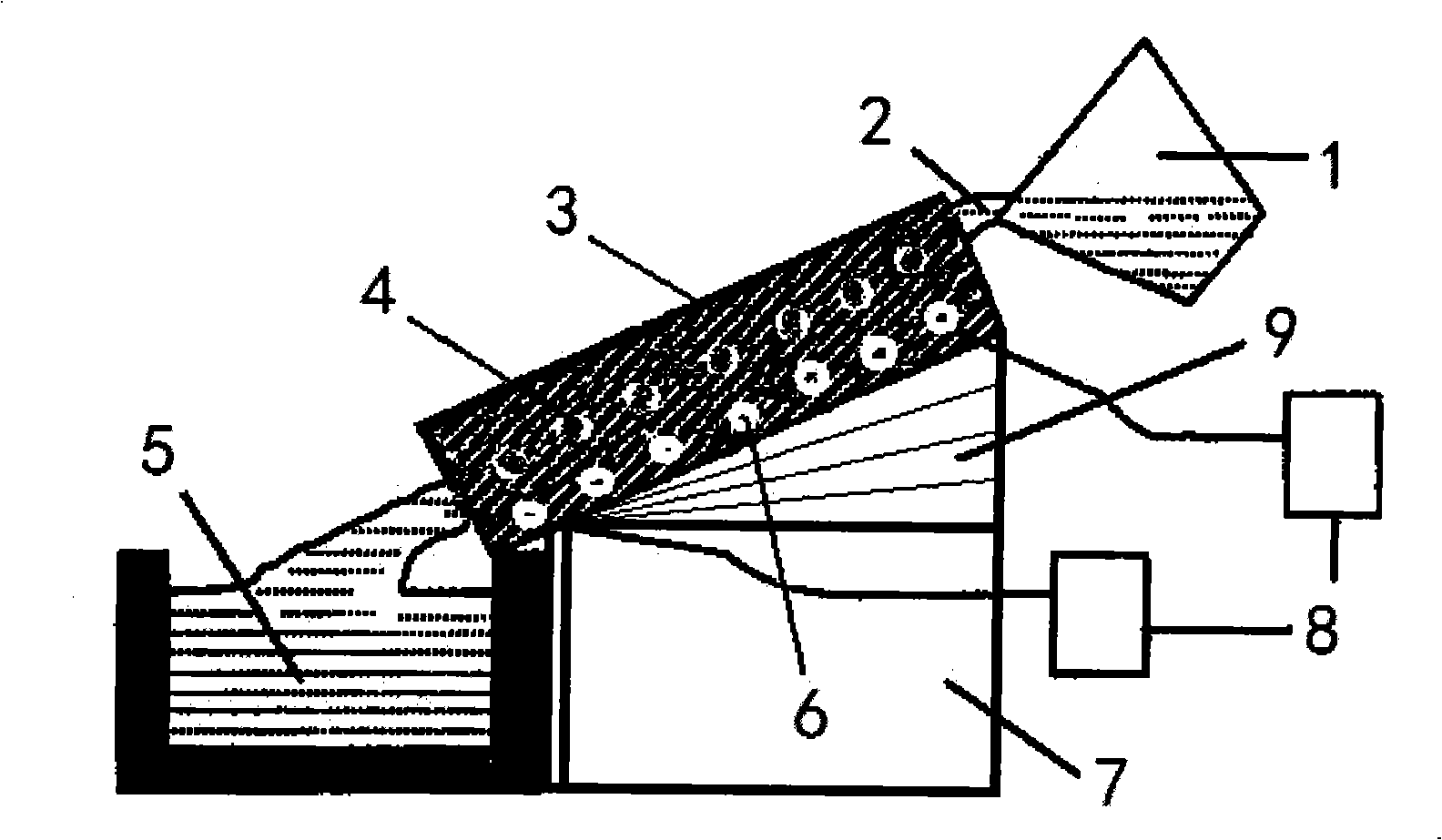

[0026] In order to understand the present invention more clearly, the present invention will be further described in detail below by taking 2Al2 alloy as an example in conjunction with the accompanying drawings. The chemical composition of 2Al2 alloy is: Si - 0.50%, Fe - 0.50%, Cu - 4.3%, Mn - 0.5%, Mg - 1.5%, Al - the balance. The differential thermal analysis determined that the liquidus temperature of the alloy was 660°C, and the solidus temperature was 620°C. The process is as follows:

[0027] (1) Heat the test alloy in a melting crucible furnace to a high temperature of 750°C for melting and refining; then cool the alloy melt to a pouring temperature of 700°C and keep it warm for 10 minutes to homogenize the temperature and composition of the alloy melt.

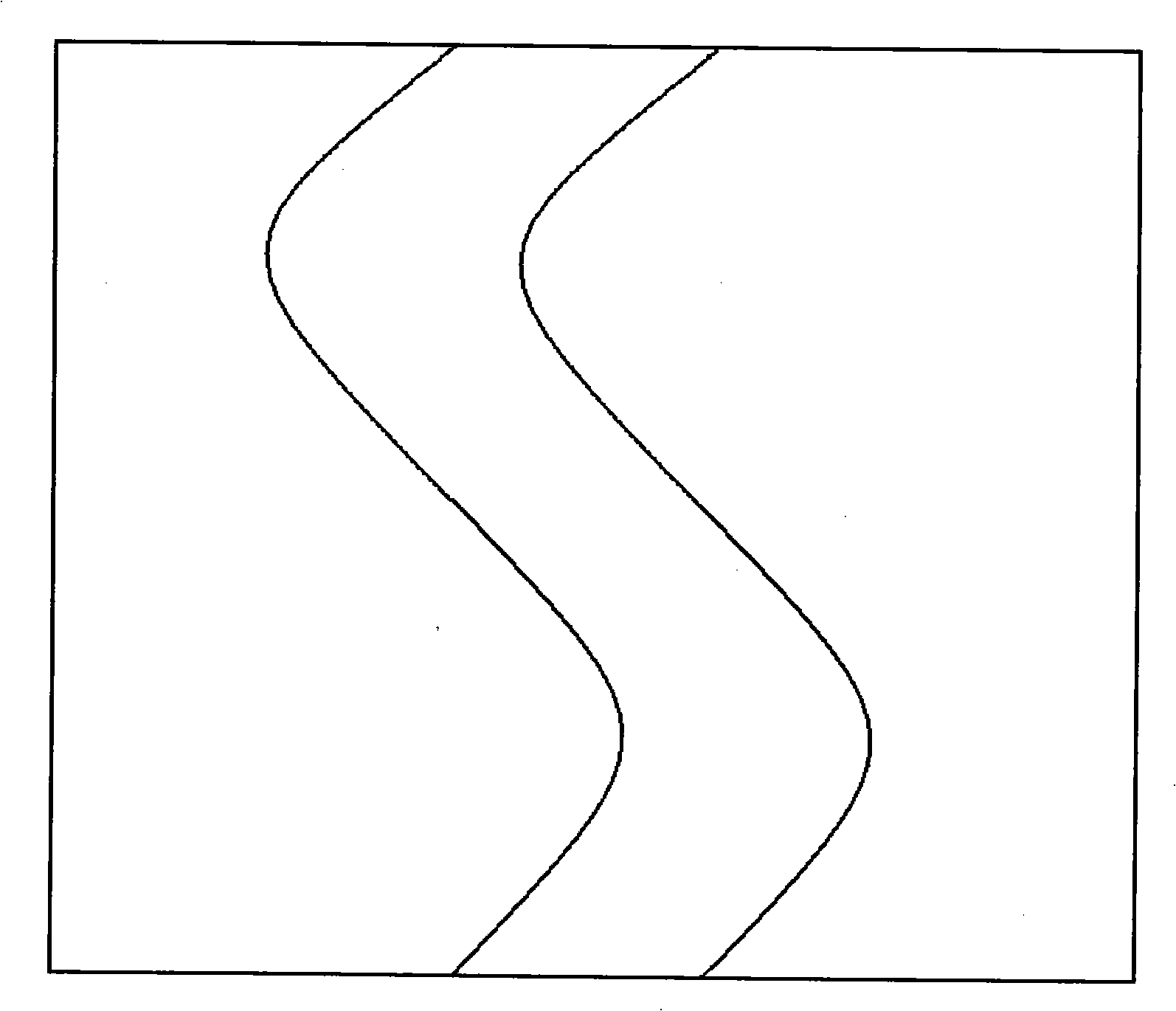

[0028] (2) Overheating pouring When the molten alloy meets the process requirements, it is poured into the inlet container in front of the channel of the sinusoidal wave container, and the height of the pressure head ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com