Highly efficient drying device for pole coils and drying method thereof

A drying device and pole roll technology, applied in drying gas arrangement, heating device, drying solid materials, etc., can solve the problems of low drying efficiency and poor heating consistency, and achieve the effect of improving drying efficiency, uniform temperature and improving heating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

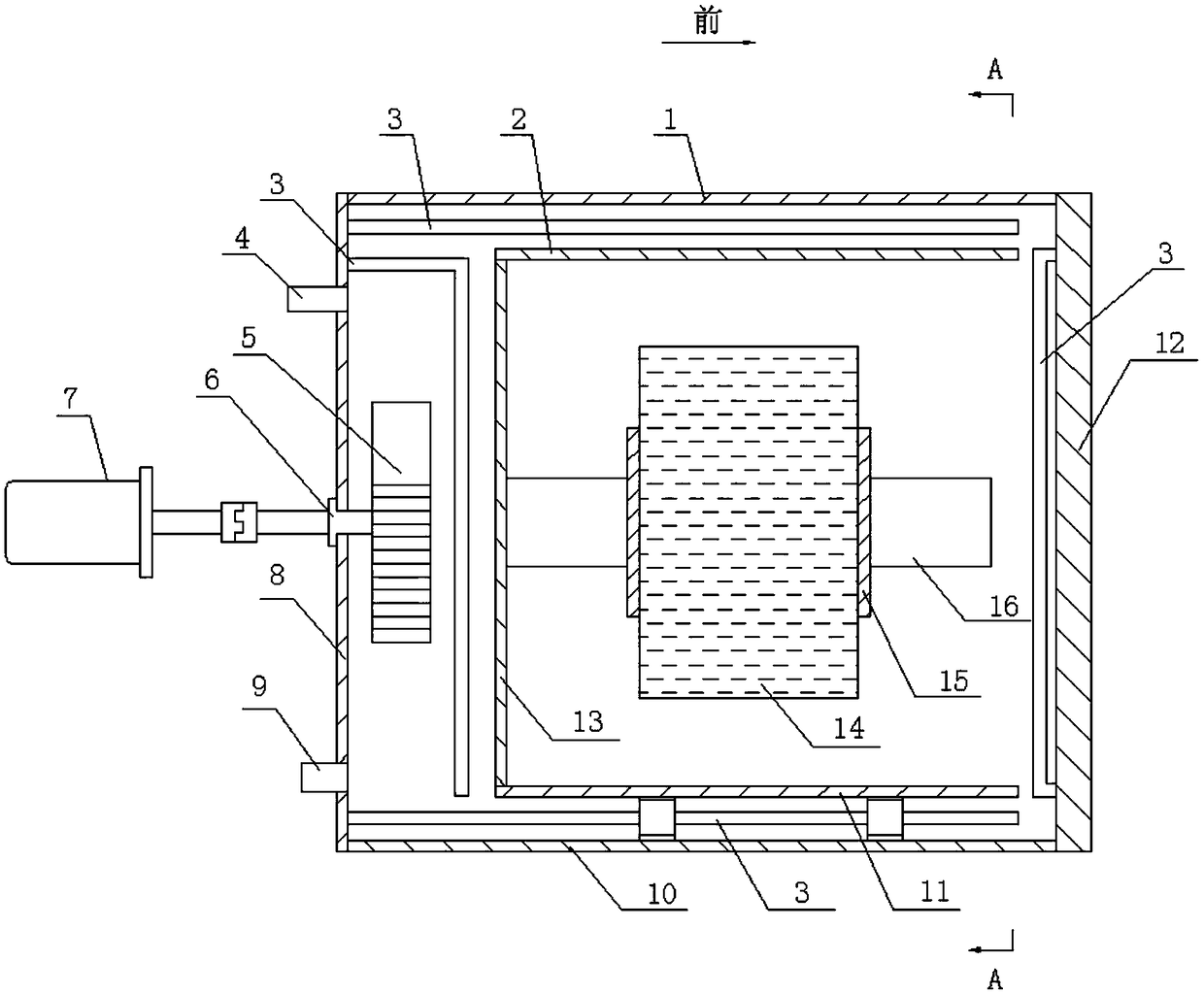

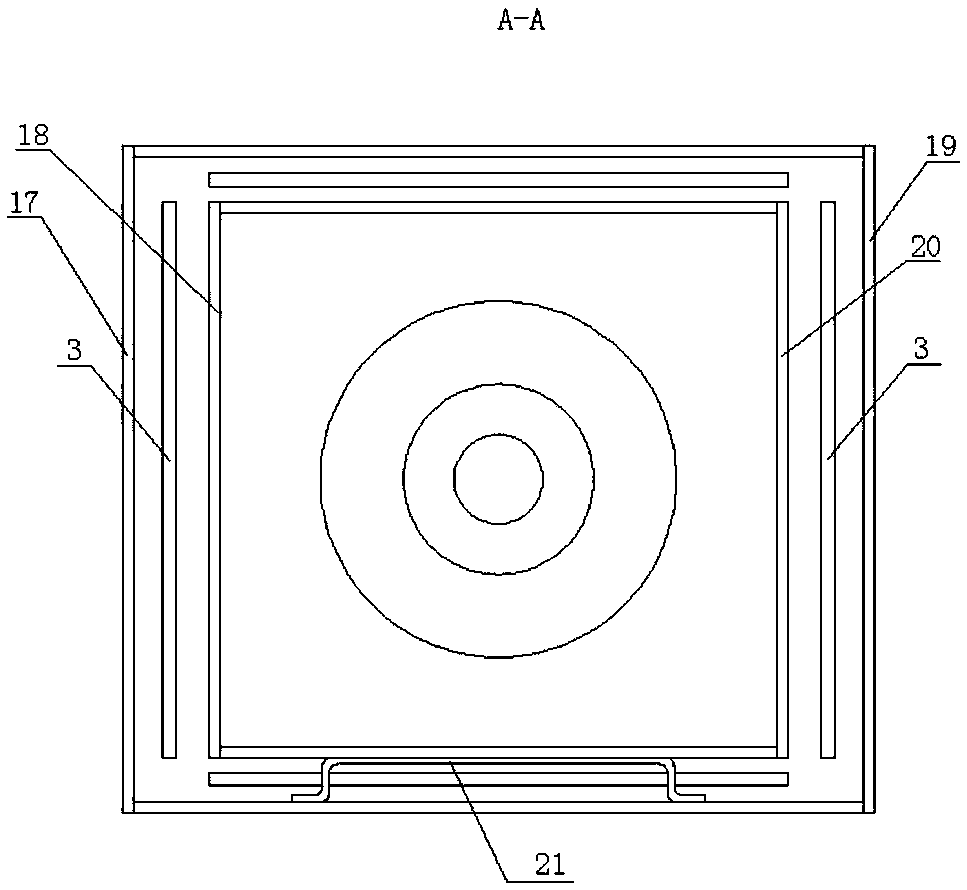

[0035] The following is a detailed description of a very high-efficiency drying method and device provided by the present invention with reference to the accompanying drawings. Aiming at the problems of low heating efficiency of large coils, uneven heating rate at different coil diameters, and high-temperature oxidation of foil materials in the preparation process of power lithium-ion batteries, the present invention provides a high-efficiency drying method for pole coils. And device thereof, described baking device specifically comprises outer box body (by outer box body upper plate 1, outer box body lower plate 10, outer box body left wall plate 17, outer box body right wall plate 19, outer box body Rear plate 8, outer box box door 12 form), drying cavity (by drying cavity upper plate 2, drying cavity lower plate 11, drying cavity left wall plate 18, drying cavity right wall plate 20, drying cavity Body rear plate 13 is formed), heater 3, transport wind motor 7, wind wheel 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com