Water-based graphite-based high-temperature bonding solid lubricant and preparation method and application thereof

A solid lubricant, graphite-based technology, applied in the field of tribology, can solve the problems of narrow temperature range of glass lubricants, compounding, material structure performance decline, etc., to improve uniform dispersion and economic performance, improve lubrication effect, Easy to coat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. Preparation of lubricant:

[0053] Raw material components: 10wt% graphite; 8wt% silicon dioxide; 8wt% phosphate binder; 1wt% cetyltrimethylammonium chloride; 0.1wt% polydimethylsiloxane 0.5 wt% of 2,6-di-tert-butyl-p-cresol; 72.4 wt% of deionized water.

[0054] 2. Preparation of lubricating coating:

[0055] (1) Mix the above-mentioned graphite and silicon dioxide in the weight ratio, and grind so as to obtain the main lubricating agent. (2) Mix and stir the components of binder, dispersant, defoamer and antioxidant meeting the above mass ratio with deionized water evenly, so as to obtain a mixed aqueous solution. (3) Add the main lubricating agent into the mixed aqueous solution, and stir to obtain a water-based graphite-based high-temperature bonded solid lubricant.

[0056] Use a spray gun to spray the above-mentioned water-based graphite-based high-temperature bonded solid lubricant on the surface of the metal workpiece under compressed air (no oil) or compr...

Embodiment 2

[0070] Prepare water-based graphite-based high-temperature bonded solid lubricant according to the method substantially the same as Example 1, and the gained lubricant is made into lubricating coating and carries out performance test, difference is,

[0071] (1) lubricant raw material components: 10wt% graphite; 10wt% silicon dioxide; 8wt% phosphate binder; 1wt% cetyltrimethylammonium chloride; Methylsiloxane; 0.5 wt% of 2,6-di-tert-butyl-p-cresol; 70.4 wt% of deionized water.

[0072] (2) The temperature in the performance test is 800°C.

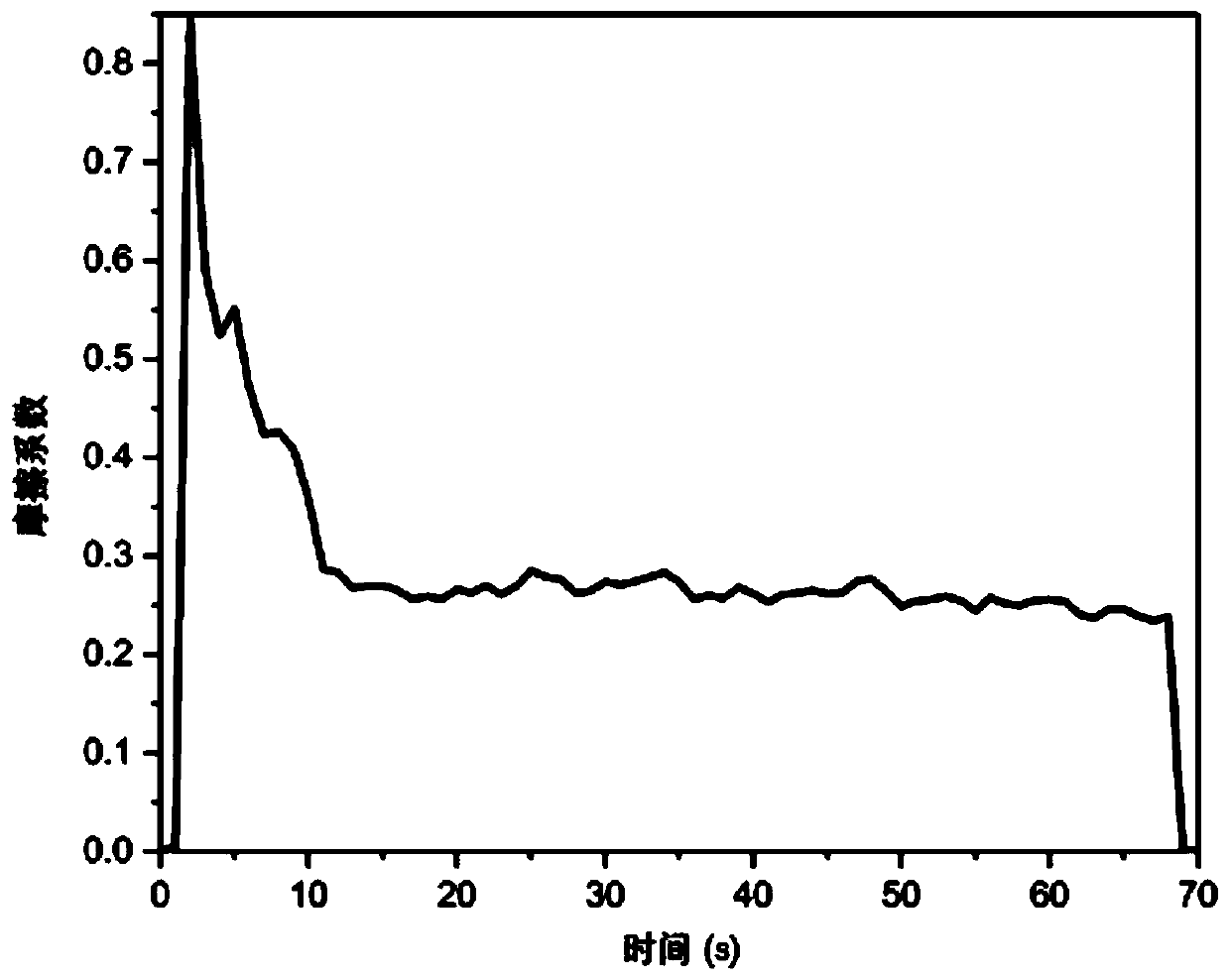

[0073] The test results show that within the test period, the friction coefficient of the coating is stable at ~0.25 after running and melting, and the lubricating coating can fully meet the lubrication requirements of the extrusion process. No matter inside or outside the wear scar area, the color of the coating is still black, and there is an enamel luster in the wear scar area, indicating that graphite still exists after the high temper...

Embodiment 3

[0075] Prepare water-based graphite-based high-temperature bonded solid lubricant according to the method substantially the same as Example 1, and the gained lubricant is made into lubricating coating and carries out performance test, difference is,

[0076] (1) lubricant raw material components: 10wt% graphite; 12wt% silicon dioxide; 8wt% phosphate binder; 1wt% cetyltrimethylammonium chloride; Methylsiloxane; 0.5 wt% of 2,6-di-tert-butyl-p-cresol; 68.4 wt% of deionized water.

[0077] (2) The temperature in the performance test is 900°C.

[0078] The test results show that within the test period, the friction coefficient of the coating is stable at ~0.25 after running and melting, and the lubricating coating can fully meet the lubrication requirements of the extrusion process. No matter inside or outside the wear scar area, the color of the coating is still black, and there is an enamel luster in the wear scar area, indicating that graphite still exists after the high temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com