Low-temperature aseptic system and process for filling plastic bottled drink

A technology of aseptic filling and batching system, which is applied in the fields of fruit juice beverages, filling equipment and technology, and aseptic filling of concentrated tea beverages in plastic bottles. It can solve the problems of easy loss of nutrients and poor taste, and achieve heating time Short, small heat loss, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

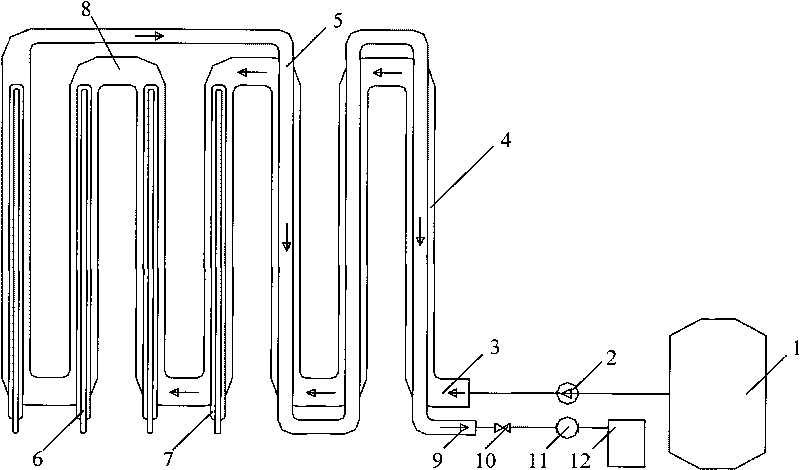

[0019] The specific structure, principle and technological process of the present invention will be further described below in conjunction with the accompanying drawings.

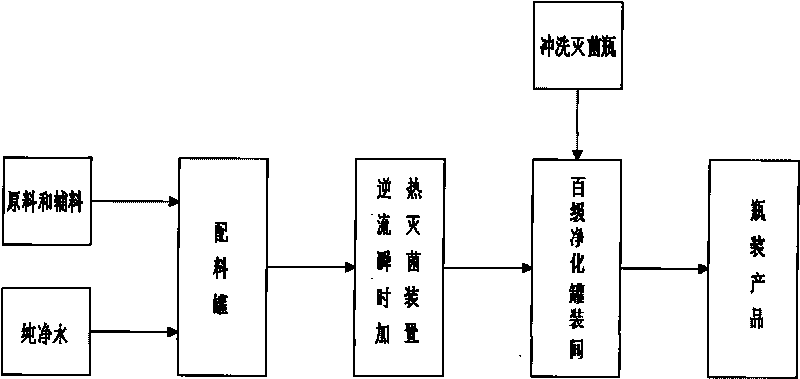

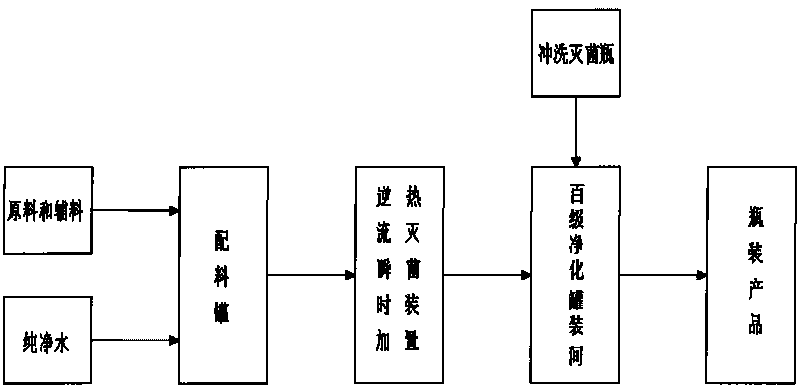

[0020] figure 1 The process flow chart of the low-temperature aseptic filling of plastic bottled beverages provided by the present invention, the filling process mainly includes process links such as batching, heating and sterilization, and bottle rinsing and filling, which specifically includes the following steps:

[0021] 1) Put tea or fruit juice raw materials and auxiliary materials and drinking purified water in the batching tank according to the required ratio, stir evenly, and the stirring time is generally 25 to 30 minutes to form filling materials;

[0022] 2) Use a high-pressure pump to send the filling material into the countercurrent instantaneous heating and sterilization device, and the material sequentially enters the inlet material flow inlet pipe 4 in the countercurrent heat exchange pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com