Short-process preparation method of thin specification high-manganese steel plate

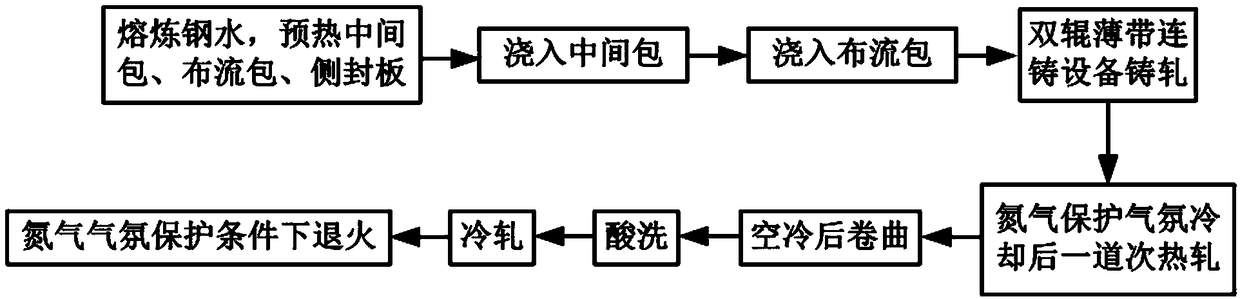

A thin-gauge, short-process technology, which is applied in the field of short-process preparation of thin-gauge high-manganese steel sheets, achieves good quality, reduces the thickness of iron oxide scale, and prevents high-temperature oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the short-process preparation method of thin-gauge high-manganese steel plate includes the following steps:

[0029] (1) Melt molten steel according to the stated composition. The smelting process is: pre-desulfurization of molten iron, converter smelting, argon station, and LF ladle furnace refining. The composition by mass percentage is: C 0.015%, Mn 15%, Si 3%, Al 3 %, P 0.003%, O 0.002%, N 0.002%, S 0.003%, and the balance is Fe.

[0030] (2) Control the temperature of the molten steel on the upper surface of the ladle to 1730°C, preheat the temperature of the tundish to 1350°C, preheat the temperature of the ladle to 1330°C, and preheat the temperature of the side sealing plate to 1300°C, pour the molten steel in the ladle poured into the tundish, then poured from the tundish into the cloth flow ladle, and then poured from the cloth flow ladle into the twin-roll thin strip continuous casting equipment. Obtain a cast strip with a thickness of 3....

Embodiment 2

[0035] In this embodiment, the short-process preparation method of thin-gauge high-manganese steel plate includes the following steps:

[0036] (1) Smelting molten steel according to the stated composition, the smelting process is: pre-desulfurization of molten iron, converter smelting, argon station, LF ladle furnace refining, the composition by mass percentage is: C 0.3%, Mn 25%, Si 1%, Al 3 %, P 0.002%, O 0.001%, N 0.0012%, S 0.0013%, and the balance is Fe.

[0037] (2) Control the temperature of the molten steel on the upper surface of the ladle to 1710°C, preheat the temperature of the tundish to 1300°C, preheat the temperature of the ladle to 1280°C, preheat the temperature of the side sealing plate to 1250°C, pour the molten steel in the ladle poured into the tundish, then poured from the tundish into the cloth flow ladle, and then poured from the cloth flow ladle into the twin-roll thin strip continuous casting equipment. Obtain a cast strip with a thickness of 3mm; ...

Embodiment 3

[0042] In this embodiment, the short-process preparation method of thin-gauge high-manganese steel plate includes the following steps:

[0043] (1) Smelting molten steel according to the stated composition, the smelting process is: pre-desulfurization of molten iron, converter smelting, argon station, LF ladle furnace refining, the composition by mass percentage is: C 0.2%, Mn 20%, Si 1.2%, Al 1.5 %, P 0.0013%, O0.0012%, N0.002%, S 0.0013%, and the balance is Fe.

[0044] (2) Control the temperature of the molten steel on the upper surface of the ladle to 1720°C, preheat the temperature of the tundish to 1330°C, preheat the temperature of the ladle to 1300°C, and preheat the temperature of the side sealing plate to 1280°C, pour the molten steel in the ladle poured into the tundish, then poured from the tundish into the cloth flow ladle, and then poured from the cloth flow ladle into the twin-roll thin strip continuous casting equipment. Obtain a cast strip with a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com