Titanium pipeline argon arc welding process method

A technology of argon arc welding and process method, which is applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of easy generation of cracks, pores and surface oxidation, low strength, plasticity and toughness of welded joints, etc., and achieves easy grinding and removal. , The effect of protecting health and smooth arc ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

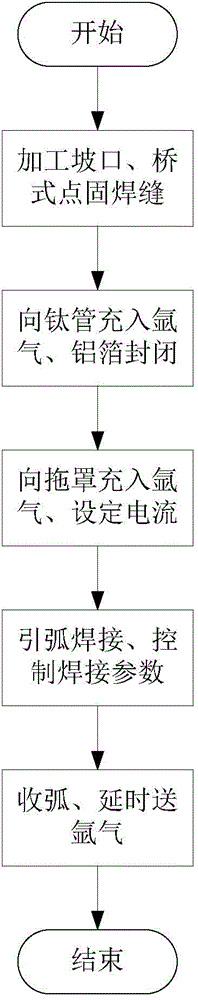

[0024] like figure 1 As shown, the titanium pipeline argon arc welding process method of the present invention comprises the following steps:

[0025] Step 1. Before starting welding, first use a vertical milling cutter to bevel the welding surface of the titanium pipe, and use a vertical milling cutter to process the bevel, which can avoid the angle grinder, lathe, and high-speed beveling machine. The over-burning phenomenon formed when the groove is formed, and then the joints are assembled on the groove, and the upper part of the groove is spot-fixed to form a bridge-type spot-fixed weld. Since the traditional spot-fixed welding is used, the shielding gas protects the spot-fixed weld. The effect is not enough (the air ratio around the groove is high at this time), and the spot welding seam is prone to defects such as pores and oxidation, and the bridge spot welding technology of the present invention is adopted, that is, the upper part of the groove is spot welded to form a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com