Thermoelectric modules

A thermoelectric module, thermoelectric semiconductor technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric devices using only Peltier or Seebeck effect, etc. Matching and other issues to achieve the effect of ensuring insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

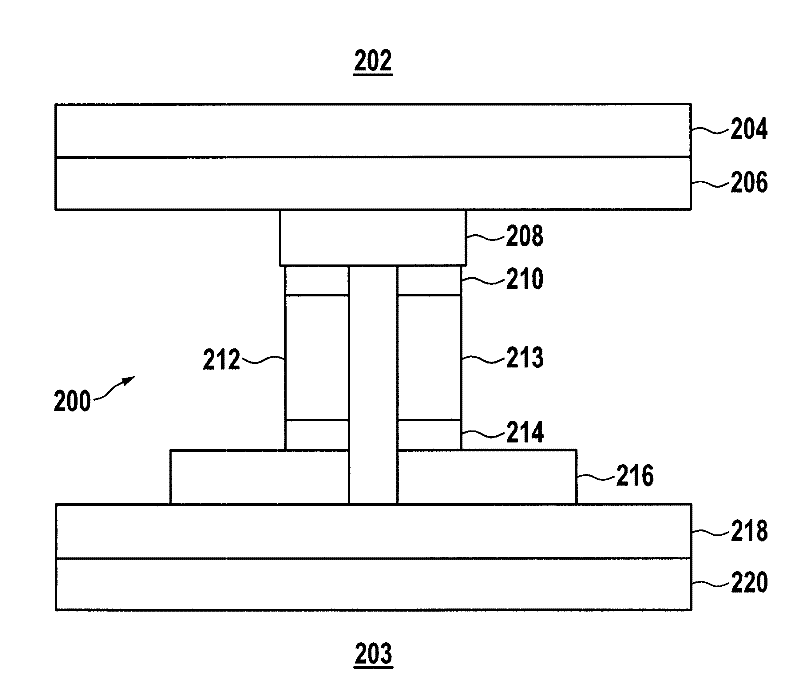

[0032] image 3 An embodiment of a thermoelectric module 300 according to the invention is shown. The module 300 comprises a plurality of p-type thermoelectric semiconductors 302 and a plurality of n-type thermoelectric semiconductors 304 , which are in each case electrically connected to each other via a connection layer 306 by means of conductor tracks 308 in a suitable manner. The conductor track 308 can consist of Cu, for example. The conductor tracks 308 lie on a base carrier 310 which includes a graded metal-matrix composite (“Metal-Matrix-Composite”, MMC). The gradient of MMC is characterized by arrows 311 pointing in the direction of increasing metal content. exist image 3 In the example of , the gradient is discrete, ie the basic support 310 comprises a total of five different layers, which are indicated by reference numerals 312-320. The layers differ in the porosity of the preform from which the base carrier 310 is produced, or correspondingly in the metal conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com