Preparation method of polyurethane-nano kaolin composite material

A technology of nano-kaolin and composite materials, which is applied in the field of polymer composite materials to achieve the effects of excellent comprehensive performance, good fluidity and dispersibility, and excellent fluidity and dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

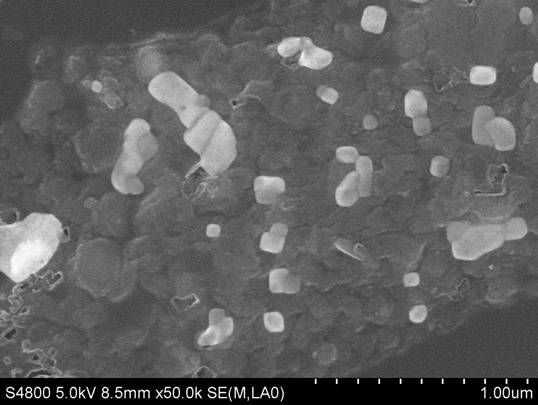

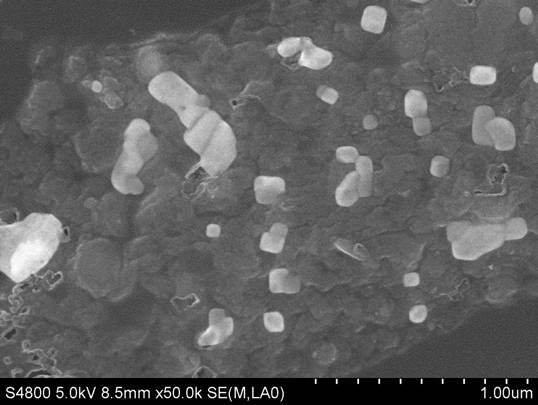

Image

Examples

Embodiment 1

[0040] The raw materials used for preparing polypropylene glycol-1000 and nano kaolin composite are as follows:

[0041] Nano Kaolin 1 part,

[0042] 24 parts of dimethyl sulfoxide,

[0043] 4 parts methanol,

[0044] Potassium acetate 15 parts,

[0045] 25 parts of distilled water,

[0046] Polypropylene glycol-1000 25 parts;

[0047] The raw materials used to prepare the polyurethane-nano kaolin composite material are as follows:

[0048] Polypropylene Glycol-1000 and Nano Kaolin Complex 35 parts,

[0049] 20 parts of toluene diisocyanate,

[0050] Polypropylene glycol-glycerol ether-3000 17 parts,

[0051] 1,4-butanediol 5 parts,

[0052] 5 parts of 3,3'-dichloro-4,4'-diaminodiphenylmethane,

[0053] Dimethyl methyl phosphate 5 parts,

[0054] 1.2 parts of release agent,

[0055] Stannous octoate 0.1 parts,

[0056] 10 parts of dimethoxyethyl phthalate.

[0057] The preparation of polyurethane-nano kaolin composite material comprises the following steps:

[00...

Embodiment 2

[0067] The preparation of polytetrahydrofuran ether glycol-1000 and nano-kaolin composite includes the following raw materials:

[0068] Nano Kaolin 4 parts,

[0069] 20 parts of dimethyl sulfoxide,

[0070] 2 parts methanol,

[0071] 10 parts of distilled water,

[0072] 10 parts of N-methylformamide,

[0073] Polytetrahydrofuran ether glycol-1000 30 parts;

[0074] The preparation of polyurethane-nanometer kaolin composite material comprises the following raw materials:

[0075] Polytetrahydrofuran ether glycol-1000 and nano kaolin complex 40 parts,

[0076] 30 parts of diphenylmethane diisocyanate,

[0077] Polyethylene glycol-glycerol-propylene glycol ether 5 parts,

[0078] 7 parts of propylene glycol,

[0079] 3 parts of dimethylthiotoluenediamine,

[0080] 2 parts diethyl ethyl phosphate,

[0081] 1 part release agent,

[0082] 0.05 parts of dibutyltin dilaurate,

[0083] Dibutyl phthalate 15 parts.

[0084] Concrete preparation method is with embodiment 1....

Embodiment 3

[0086] The preparation of polyoxypropylene-oxyethylene ether glycol-1000 and nano kaolin composite includes the following raw materials:

[0087] Nano Kaolin 7 parts,

[0088] 27 parts of dimethyl sulfoxide,

[0089]6 parts of methanol,

[0090] 20 parts of hydrazine,

[0091] 10 parts of distilled water,

[0092] Polyoxypropylene-oxyethylene ether glycol-1000 30 parts;

[0093] The preparation of polyurethane-nanometer kaolin composite material comprises the following raw materials:

[0094] Polyoxypropylene-oxyethylene ether glycol-1000 and nano-kaolin complex 40 parts,

[0095] 30 parts of isophorone diisocyanate,

[0096] 10 parts of polyadipate-glycerol-ethylene glycol ester,

[0097] Hydroquinone-bis(β-hydroxyethyl)ether 12 parts,

[0098] 6 parts of dimethylthiochlorophenylenediamine,

[0099] 10 parts of triphenyl phosphite,

[0100] 1.5 parts of release agent,

[0101] 0.1 parts each of dibutyltin dilaurate and stannous octoate.

[0102] Concrete preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com