Nanometer heat dissipating paint and preparation method thereof

A heat-dissipating coating and nano-technology, applied in the coating and other directions, can solve the problems of low heat dissipation, reduced heat dissipation of the heat dissipation layer, high price, etc., and achieve the effect of uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

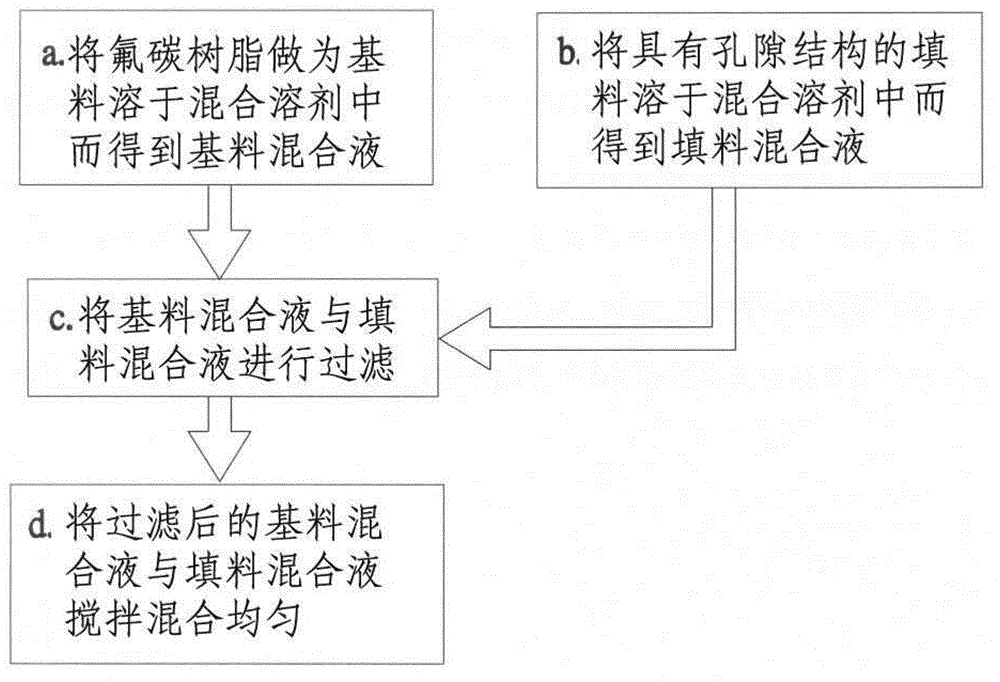

[0013] First, see the " figure 1 ", the preparation method of nano heat-dissipating coating of the present invention comprises the following steps: a. dissolving the fluorocarbon resin in the mixed solvent as the base material to obtain the base material mixed solution, and the weight ratio of the base material to the mixed solvent 0.9 to 1.4 times; b. The filler with a pore structure whose weight ratio is 0.2 to 0.33 times that of the base material is dissolved in a mixed solvent to obtain a filler mixed solution, and the weight ratio of the filler to the mixed solvent is 0.3 to 0.6 c. filter the base material mixture obtained through step a and the filler mixture obtained through step b using a 350-mesh screen; and d. filter the base mixture and filler mixture obtained through step c The shearing emulsifier stirs at high speed to mix evenly.

[0014] Furthermore, the first embodiment of the nano heat-dissipating coating of the present invention is to dissolve 120g of fluoro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com