Low-viscosity two-component sealant and preparation method thereof

A two-component, sealant technology, used in adhesives, epoxy resins, adhesive types, etc., can solve problems such as reduced heat dissipation performance, corrosion of electronic precision components, short circuits, etc., and is conducive to uniform dispersion and thixotropy. Exponentially high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

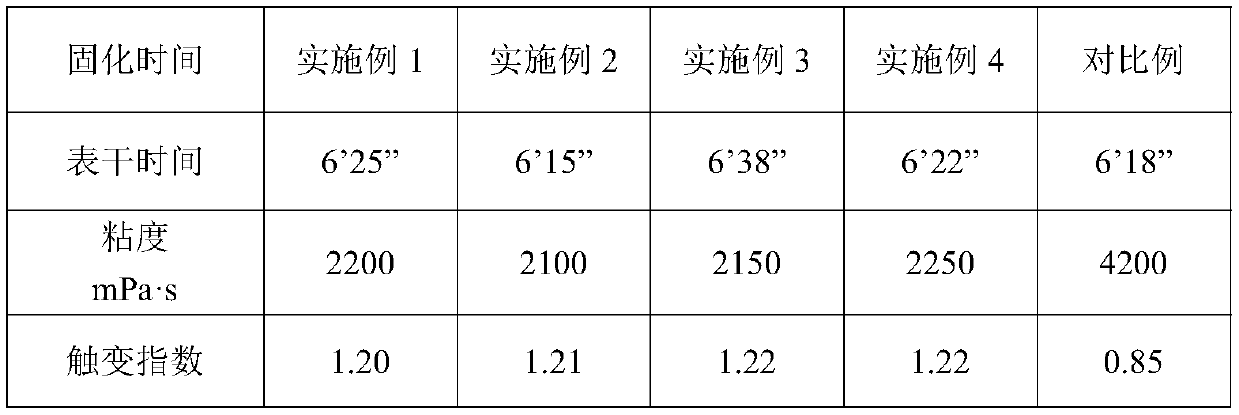

Examples

Embodiment 1

[0022] A low-viscosity two-component sealant, including A component and B component, A component includes 100 parts of α, ω-dihydroxypolysiloxane, 35 parts of magnesium oxide, and 5.5 parts of hexamethyldisiloxane , 6 parts of bis(2-ethylhexyl) phthalate; component B includes 7.5 parts of hexamethyldisiloxane, 5 parts of methyltriacetoxysilane, and 7.5 parts of bisphenol A epoxy resin , 2 parts of dibutyltin dilaurate, 10 parts of bis(2-ethylhexyl) phthalate, 8.5 parts of hydrogenated castor oil, and 10 parts of diallyl glycidyl ether.

[0023] The preparation method is as follows: S1) Prepare component A, weigh α, ω-dihydroxypolysiloxane, magnesium oxide, hexamethyldisiloxane and bis(2-ethyl phthalate) in parts by weight Hexa) ester is put into a mixer for dispersion and stirring, the stirring vacuum is 0.08MPa, the stirring temperature is 125°C, the stirring time is 90min, the stirring speed is 500rpm, and the material is discharged and filled to obtain the A component; S2) ...

Embodiment 2

[0025] A low-viscosity two-component sealant, including A component and B component, A component includes 100 parts of α, ω-dihydroxypolysiloxane, 30 parts of magnesium oxide, and 7.5 parts of hexamethyldisiloxane , 12 parts of bis(2-ethylhexyl) phthalate; component B includes 4.5 parts of hexamethyldisiloxane, 1 part of methyltriacetoxysilane, and 2 parts of bisphenol A epoxy resin , 1.5 parts of dibutyl tin diacetate, 8 parts of bis(2-ethylhexyl) phthalate, 10 parts of polyethylene wax, and 10 parts of dodecyl glycidyl ether.

[0026] The preparation method is as follows: S1) Prepare component A, weigh α, ω-dihydroxypolysiloxane, magnesium oxide, hexamethyldisiloxane and bis(2-ethyl phthalate) in parts by weight Hexa) ester was put into a mixer to disperse and stir, the stirring vacuum was 0.095MPa, the stirring temperature was 115°C, the stirring time was 80min, the stirring speed was 550rpm, and the material was discharged and filled to obtain the A component; S2) Prepare ...

Embodiment 3

[0028] A low-viscosity two-component sealant, including A component and B component, A component includes 100 parts of α, ω-dihydroxypolysiloxane, 50 parts of aluminum oxide, γ-[2,3-epoxy 8 parts of propoxy]propyltrimethoxysilane, 8.5 parts of diisononyl phthalate; component B includes 2 parts of γ-[2,3-glycidoxy]propyltrimethoxysilane, methyl 2.5 parts of tributylketoxime silane, 12 parts of bisphenol A epoxy resin, 2.5 parts of dibutyltin dilaurate, 5 parts of diisononyl phthalate, 5 parts of hydrogenated castor oil, ethylene glycol glycidyl ether 20 servings.

[0029] Its preparation method is: S1) Prepare A component, weigh α, ω-dihydroxypolysiloxane, aluminum oxide, γ-[2,3-glycidyloxy]propyltrimethoxysilane by weight parts and diisononyl phthalate, put into a mixer to disperse and stir, the stirring vacuum is 0.09MPa, the stirring temperature is 125°C, the stirring time is 100min, the stirring speed is 550rpm, and the material is discharged and filled to obtain the A com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com