Waterborne polyurethane dispersion and its preparation method and application, waterborne coating

A technology of water-based polyurethane and water-based coatings, applied in the direction of polyester coatings, coatings, etc., can solve the problems of slow coating film formation speed, potential safety hazards of coatings, flammability and explosion, etc., to improve the thixotropic index and improve the alignment The effect of good ability and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

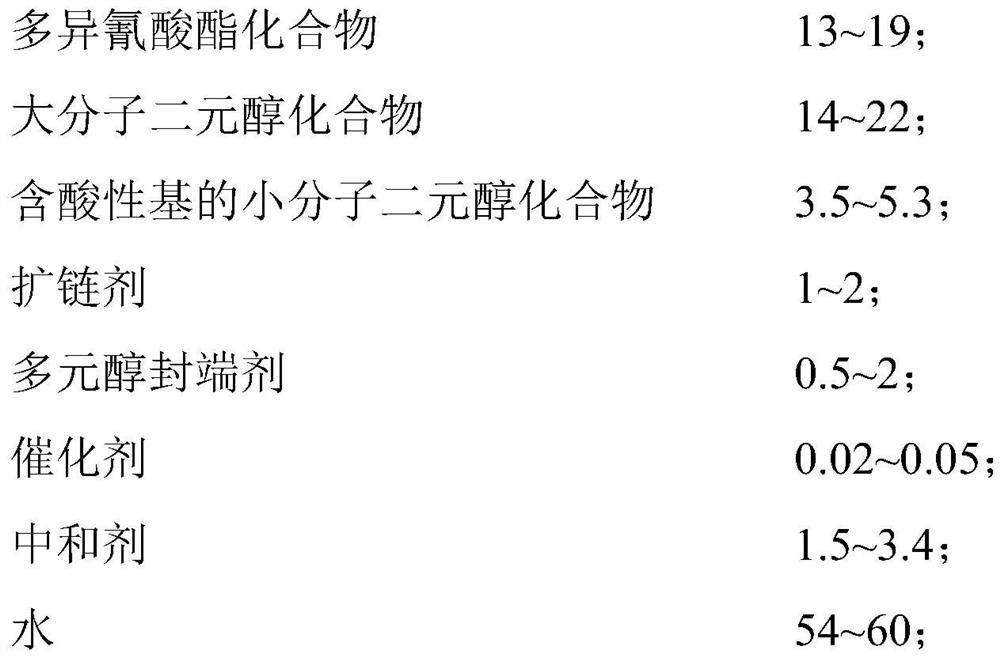

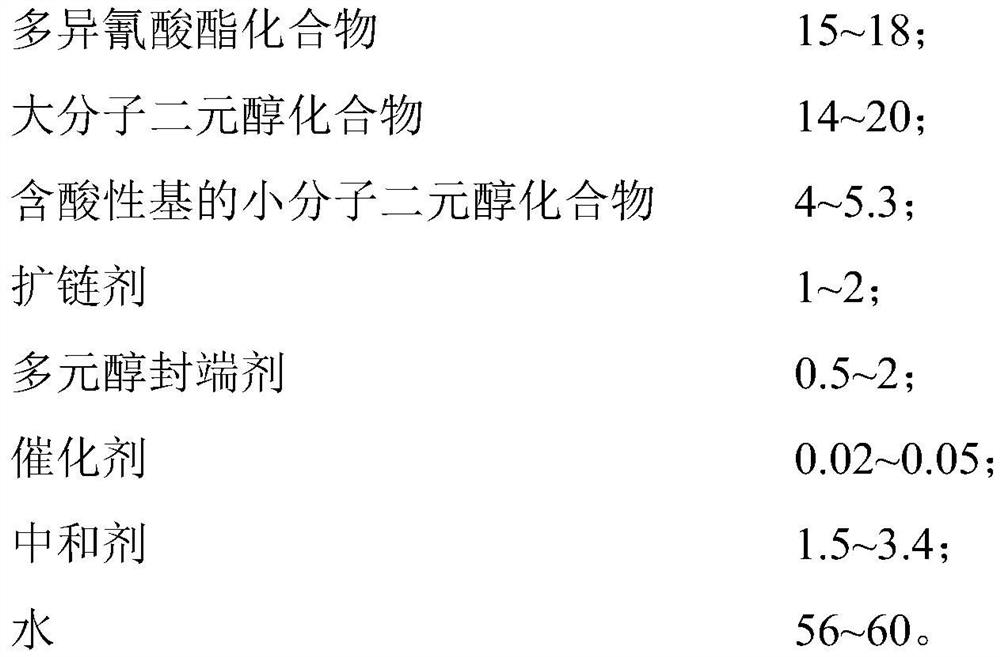

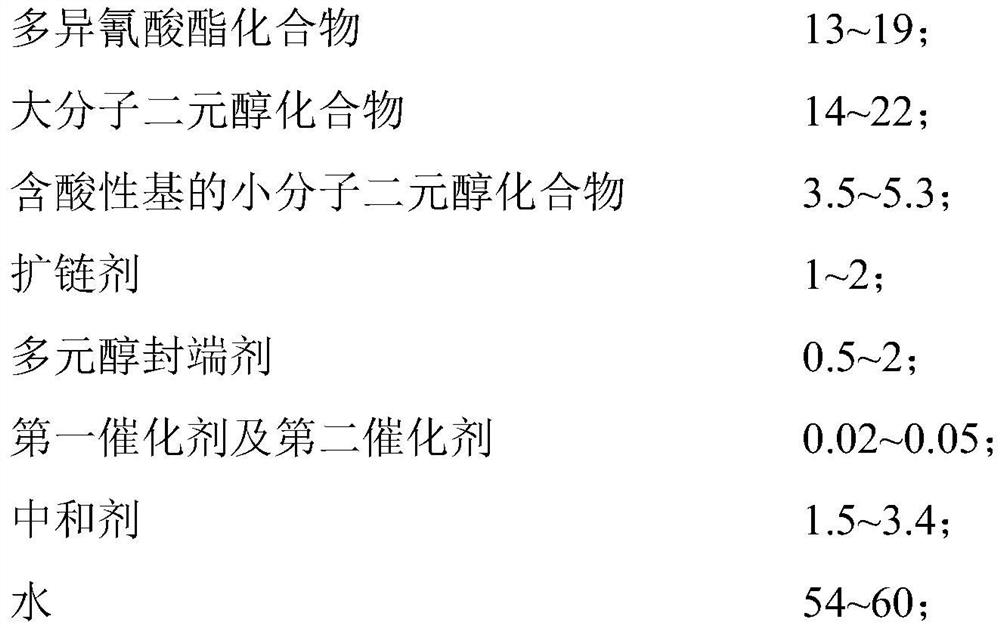

[0062] The raw materials for the preparation of the polyurethane resin include a polyurethane prepolymer, a polyol end-capping agent, the first catalyst and a neutralizing agent, and the raw materials for the polyurethane prepolymer include polyisocyanate compounds, macromolecular diol compounds, Small molecule glycol compound, chain extender and second catalyst; the raw materials for the preparation of the above water and the above polyurethane resin are as follows in parts by mass:

[0063]

[0064] In the above-mentioned water-based polyurethane dispersion, firstly, under the action of the second catalyst, the isocyanate compound, the macromolecular diol compound, the small molecule diol compound containing acidic groups and the chain extender of a specific mass fraction generate high molecular weight Polyurethane prepolymer; then the polyurethane prepolymer and the end-blocking agent are reacted under the action of the first catalyst and then neutralized by a neutralizin...

specific Embodiment

[0098] Here, according to the water-based polyurethane dispersion of the present invention, its preparation method and application, and water-based coatings, the present invention is not limited to the following examples.

[0099] Embodiment 1-5 According to the preparation method of the water-based polyurethane dispersion of the present invention, the water-based polyurethane dispersion is prepared, and the specific steps are as follows.

[0100] 1) Put the macromolecular diol compound and the diol compound containing acidic groups into the reaction kettle, and remove water under the condition of -0.09MPa negative pressure and 100°C until the water content is lower than 0.05%.

[0101] 2) Mix the polyisocyanate compound with the macromolecular diol compound after water removal and the diol compound containing acidic groups, pre-react for 30 minutes at 70-83°C, then add dibutyltin dilaurate, and then react for 1- After 2 hours, the reactant was obtained.

[0102] 3) Add the s...

Embodiment 6

[0112] Prepare the water-based paint, the specific steps are as follows.

[0113] 1) Under the stirring condition with a linear speed of 3m / s, put the weighed ethylene glycol butyl ether into the batching tank, add AL WM-6360 aluminum powder and AL 99-0779 aluminum powder while stirring, and stir for 0.5h to obtain aluminum Powder dispersion paste a.

[0114] 2) Under the condition of stirring with a linear speed of 5m / s, add the weighed CYMEL325 high imino amino resin, dipropylene glycol dimethyl ether and pH regulator (dimethylethanolamine) into the blending kettle in sequence, stir for 0.5h and mix well ; Then add the aluminum powder dispersion slurry a prepared in step 1) to the blending kettle while stirring to obtain component b.

[0115] 3) under the stirring condition that line speed is 3m / s, the aqueous polyurethane dispersion that Setaqua 6802 acrylic acid emulsion, Desmophen 1652 water-based polyester resin, Cy370 partly methylated amino resin, embodiment 1 make, n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com