Method for preparing composite cathode materials RBCO-xCGO of SOFC by in-situ colloidal composite method

A technology of solid oxides and fuel cells, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of uneven distribution and poor uniformity of impregnated particles, and achieve the effects of improving preparation performance, preventing agglomeration, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

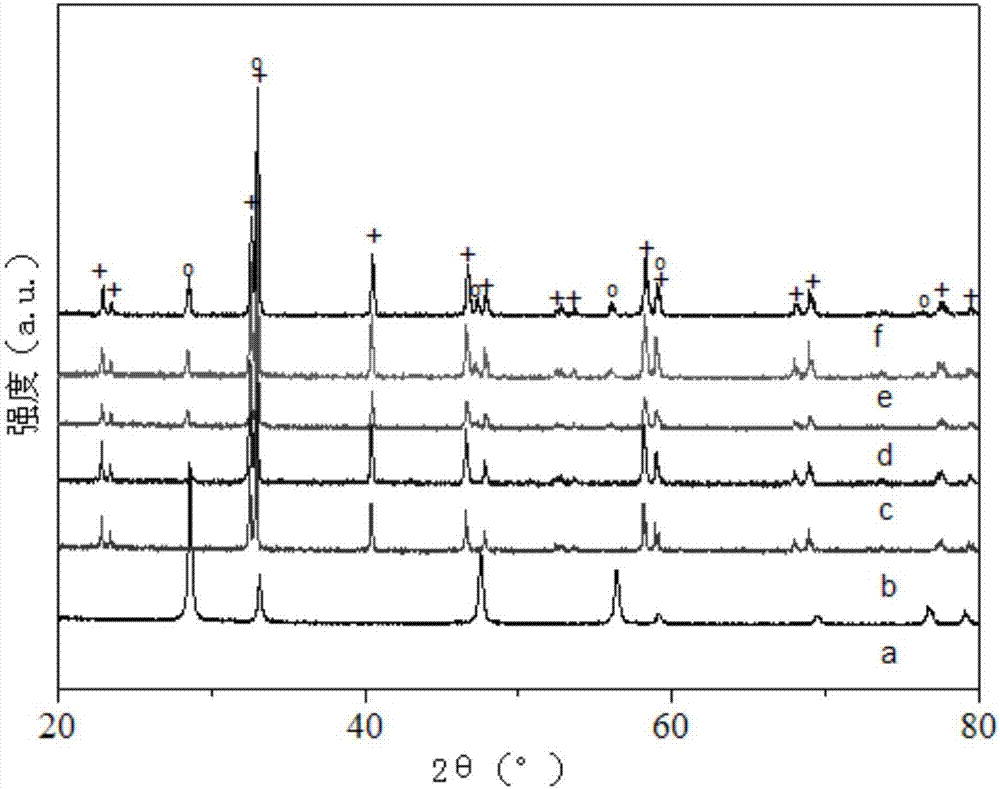

[0033] Embodiment 1: The method for preparing solid oxide fuel cell composite cathode material RBCO-xCGO by an in-situ colloidal composite method of the present embodiment is carried out according to the following steps:

[0034] 1. ReBaCo 2 O 6-δ Preparation of precursor sol: Re(NO 3 ) 3 ·6H 2 O, Ba (NO 3 ) 2 and Co(NO 3 ) 3 ·6H 2 After mixing, add deionized water, stir until it is completely dissolved at a temperature of 20-25 °C, and obtain a mixed solution, then add EDTA and citric acid, and stir at a temperature of 20-25 °C until it becomes a homogeneous solution , and then add ammonia water to adjust the pH to 6-6.5 to obtain ReBaCo 2 O 6-δ Precursor sol, wherein Re is a rare earth element;

[0035] Re(NO) described in step 1 3 ) 3 ·6H 2 O and Ba(NO 3 ) 2 The ratio of the amount of substances is 1:1;

[0036] Re(NO) described in step 1 3 ) 3 ·6H 2 O and Co(NO 3 ) 3 ·6H 2 The ratio of the amount of O substances is 1:2;

[0037] Re(NO) described in ...

specific Embodiment approach 2

[0054] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the rare earth element Re in step 1 is La, Pr, Nd, Sm or Gd. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0055] Embodiment 3: The difference between this embodiment and one of Embodiments 1 to 2 is that the Re(NO 3 ) 3 ·6H 2 The ratio of the amount of O substance to the volume of deionized water is 0.007 mol to 0.009 mol: 150 mL. Other steps and parameters are the same as one of the first to second embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com