Connection method for carbon/carbon composite materials

A carbon composite material and connection method technology, applied in the field of carbon/carbon composite material connection, can solve problems such as poor thermal shock resistance, and achieve the effects of excellent thermal shock resistance, enhanced interface bonding strength, and enhanced connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Cut the carbon / carbon composite material into 12×8×4mm 3 The rectangular parallelepiped sample was placed in a high-temperature muffle furnace at 1000°C for 8 minutes for pre-oxidation.

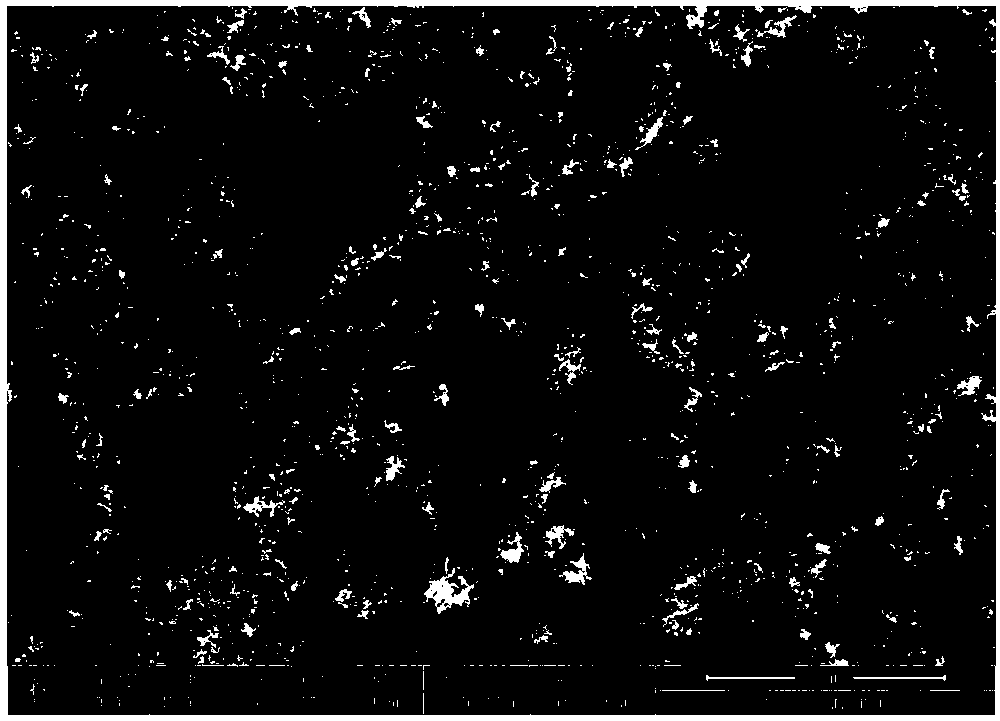

[0024] 2. Put the pre-oxidized carbon / carbon sample into a tube furnace, and use the chemical vapor deposition process to grow carbon nanotubes in situ. The growth process conditions are: xylene as the carbon source, ferrocene as the catalyst precursor, The concentration of ferrocene is 0.03g / ml, the growth temperature is 850°C, the flow rate of argon gas is 1000ml / min, the flow rate of hydrogen gas is 100ml / min, the injection rate is 0.2ml / min, and the carbon / carbon sample with carbon nanotubes grown on the surface is obtained by growing for 1h. Sample.

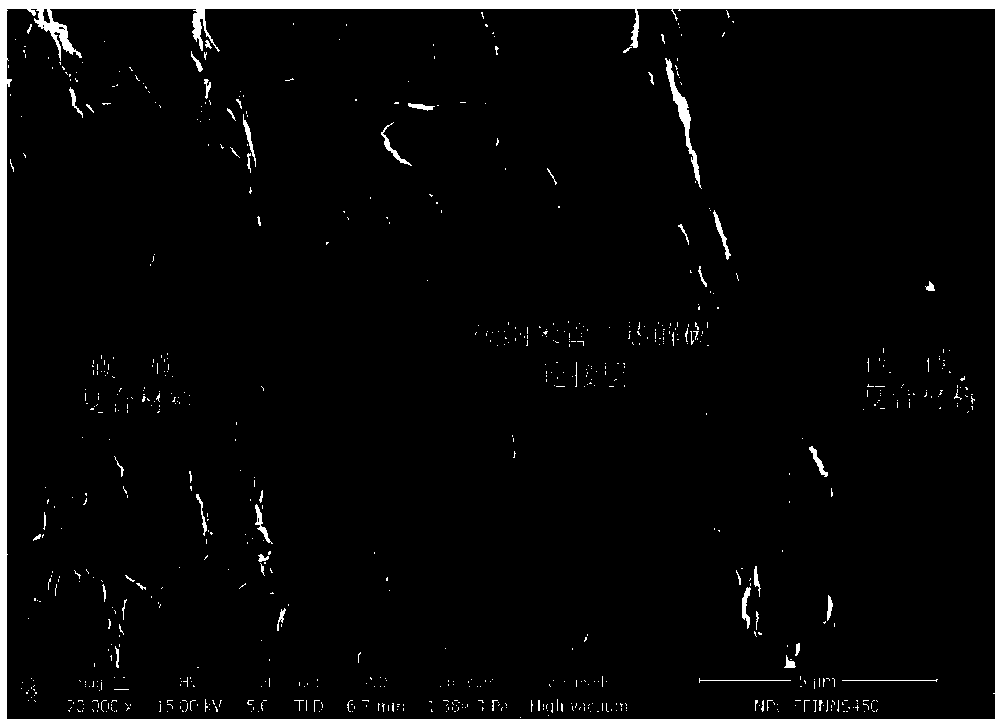

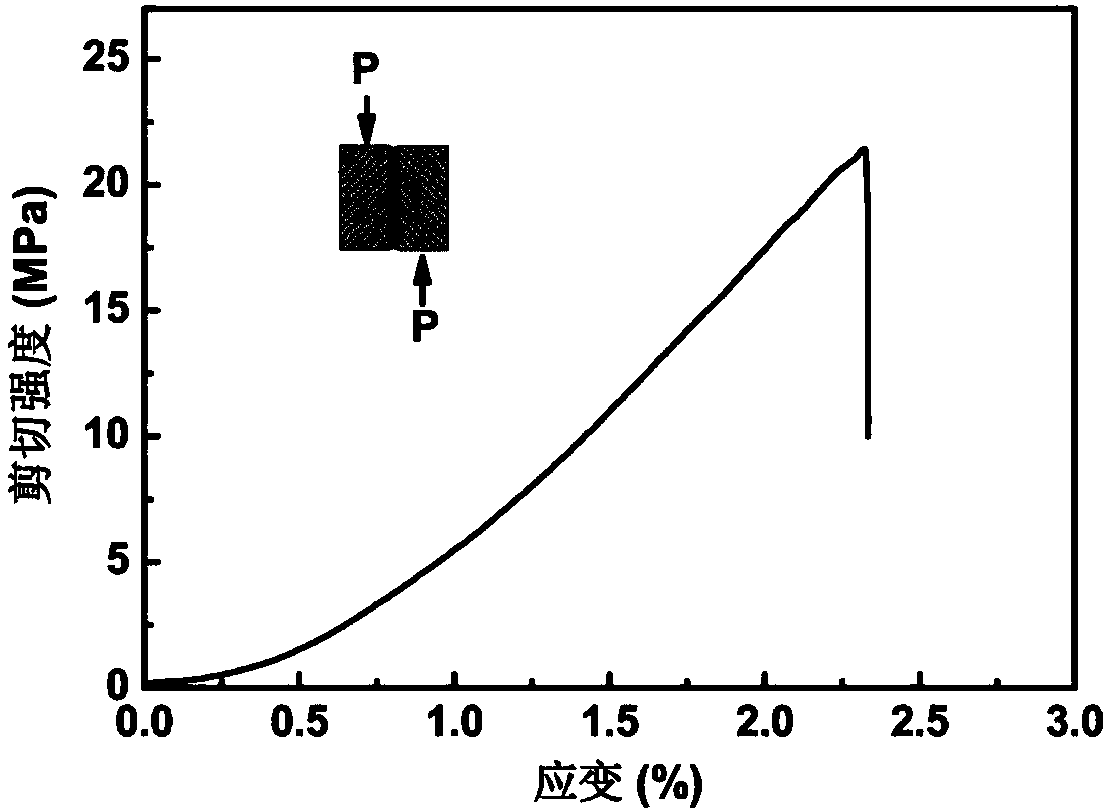

[0025] 3. Embed the carbon / carbon samples with carbon nanotubes grown on the surface and fix them with graphite fixtures, put them into a chemical vapor deposition furnace to deposit pyrolytic carbon for connection, heat the depo...

Embodiment 2

[0027] Using the same method as in Example 1, the growth time of the carbon nanotubes was adjusted to 0.5 h. The test results showed that the shear strength of the carbon / carbon sample connected by the carbon nanotubes / pyrolytic carbon intermediate layer reached 16.5 MPa.

Embodiment 3

[0029] 1. Cut the carbon / carbon composite material into 12×8×4mm 3 The rectangular parallelepiped sample was put into a high-temperature muffle furnace at 800°C for pre-oxidation for 5 minutes.

[0030] 2. Put the pre-oxidized carbon / carbon sample into a tube furnace, and use chemical vapor deposition to grow carbon nanotubes in situ. The growth process conditions are: ethanol as the carbon source, nickelocene as the catalyst precursor, and two The concentration of nickel is 0.01g / ml, the growth temperature is 900°C, the flow rate of argon gas is 300ml / min, the flow rate of hydrogen gas is 100ml / min, the injection rate is 0.5ml / min, and the carbon / carbon sample with carbon nanotubes grown on the surface is obtained by growing for 1h. .

[0031] 3. Embed carbon / carbon samples with carbon nanotubes grown on the surface together, fix them with graphite fixtures and place them in a chemical vapor deposition furnace to deposit pyrolytic carbon for connection. The deposition temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com