Nano rare earth zirconate ceramic powder material for high temperature heat barrier coat and preparation method thereof

A nano-rare earth and ceramic powder technology, which is applied in the field of rare earth zirconate ceramic powder materials and preparations for high-temperature thermal barrier coatings, can solve the problems of thermal expansion mismatch, phase change failure, and high thermal conductivity of the substrate, and achieve particle diameter The effect of small size, high melting point and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific implementation mode 1: The chemical molecular formula of the nanometer rare earth zirconate ceramic powder material for high temperature thermal barrier coating in this implementation mode is Ln 2 Zr 2 o 7 , wherein the Ln is a combination of one or more rare earth elements in Gd, Sm, Nd or Yb.

[0016] The preparation method of the nano rare earth zirconate ceramic powder material for high temperature thermal barrier coating in this embodiment is as follows:

[0017] Step 1, at room temperature, dissolve rare earth oxides with dilute nitric acid or dissolve soluble salts containing rare earth elements with deionized water to obtain Ln-containing 3+ solution, dissolving soluble zirconium salts with deionized water to obtain Zr 4+ The solution, the concentration of the two solutions is the same, both 0.1 ~ 1.0M;;

[0018] Step 2, mixing the two solutions obtained in step 1 to prepare a solution containing Ln 3+ and Zr 4+ A 1:1 mixed solution, the molar con...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and the nano-rare earth zirconate ceramic powder material for high-temperature thermal barrier coatings described in Embodiment 1 is that the Ln is Gd or Sm or Nd or Yb.

[0029] In this embodiment, Gd is used 2 o 3 Extract Gd as raw material 3+ ions, using Sm 2 o 3 Extract Sm as raw material 3+ Ions; using Nd 2 o 3 Extract Nd as raw material 3+ ion; using Yb 2 o 3 Extract Yb as raw material 3+ ion.

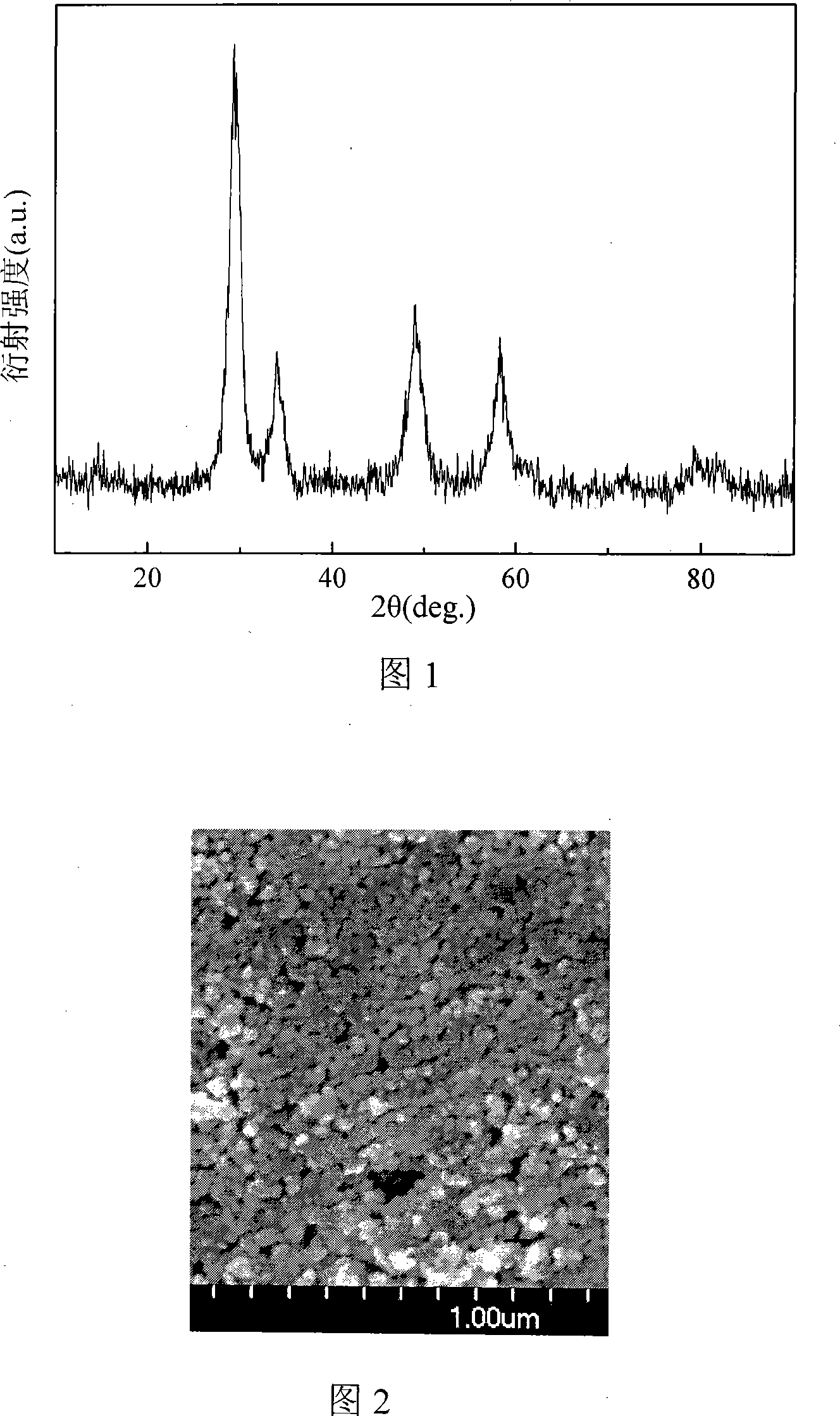

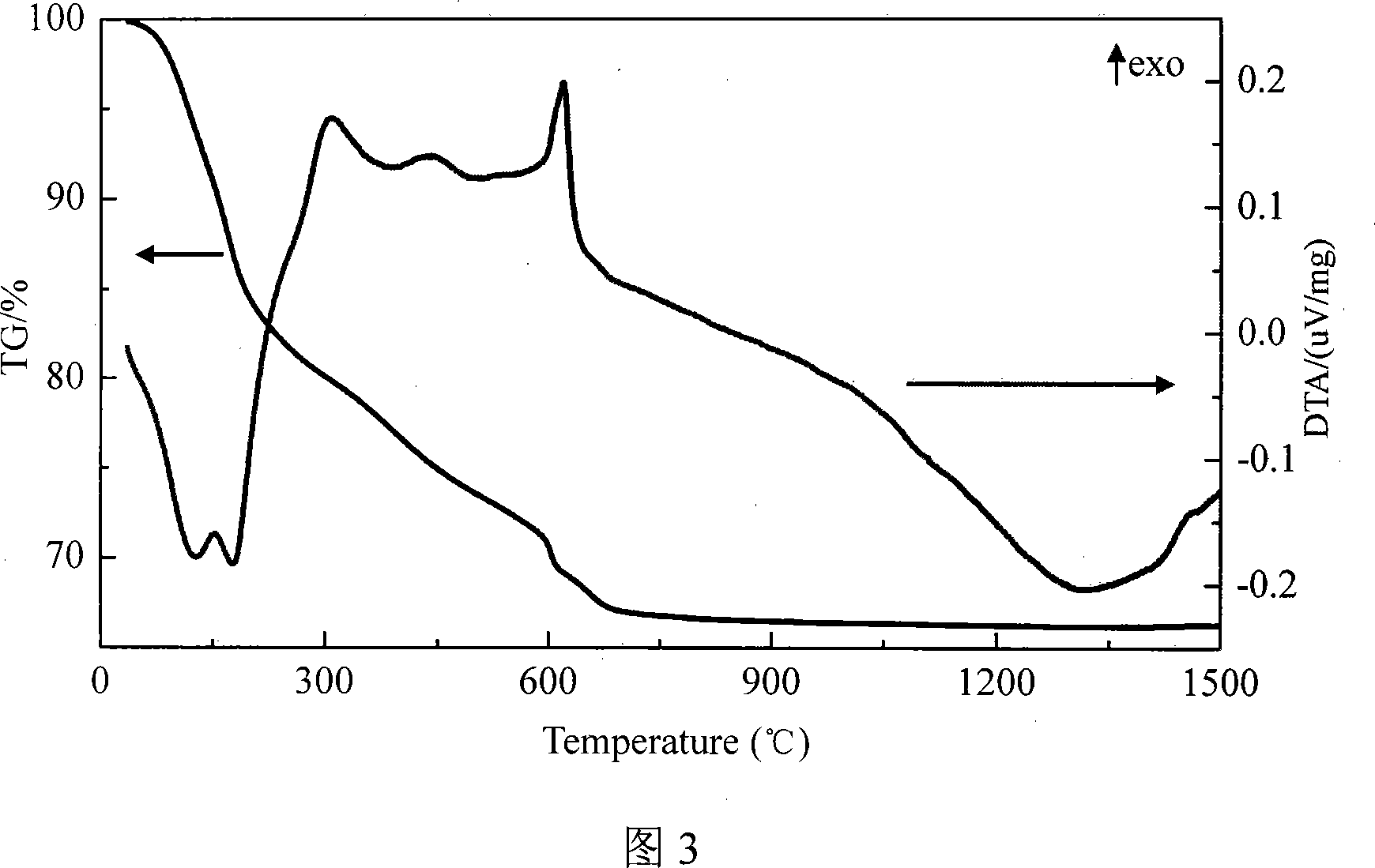

[0030] Gd described in this embodiment mode 2 Z r 2O 7 The ceramic material has a single pyrochlore phase structure, as shown in Figure 1, and its particle size is about 40 nm, as shown in Figure 2; Gd after drying at 80 °C 2 Zr 2 o 7 The TG-DTA curve of the precipitate is shown in Figure 3. It is found that the precipitate undergoes dehydration reaction around 150°C, organic matter decomposes around 300°C, and crystallizes around 600°C. No phase change, no weight loss, suitable as high temperature therm...

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and the nano-rare earth zirconate ceramic powder material for high-temperature thermal barrier coatings described in Embodiment 1 is that the Ln is Gd x SM 1-x or Nd x Yb 1-x or Gd x Nd 1-x or Gd x Yb 1-x or Sm x Nd 1-x or Sm x Yb 1-x , where x is 0.1 or 0.3 or 0.5 or 0.7 or 0.9.

[0032] The difference between the method for preparing the ceramic powder material described in this embodiment and the method described in Embodiment 1 is that in step 1, the soluble salt solution prepared by using rare earth oxides contains Gd 3+ 、Sm 3+ 、Nd 3+ and Yb 3+ Any two of them, the ratio of the two ions in the soluble salt solution is: x:(1-x).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com