Polyimide polymer composition, method for producing the same, and polyimide film

A technology of polyimide and manufacturing method, applied in the field of polyimide film, can solve the problems of inability to obtain physical properties, etc., and achieve the effect of improving transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

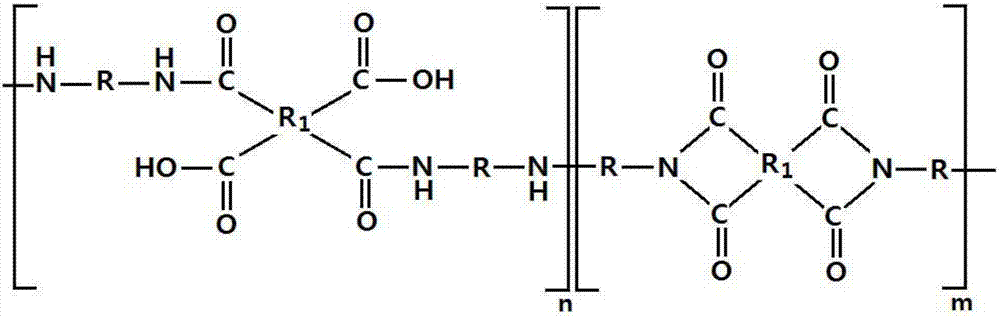

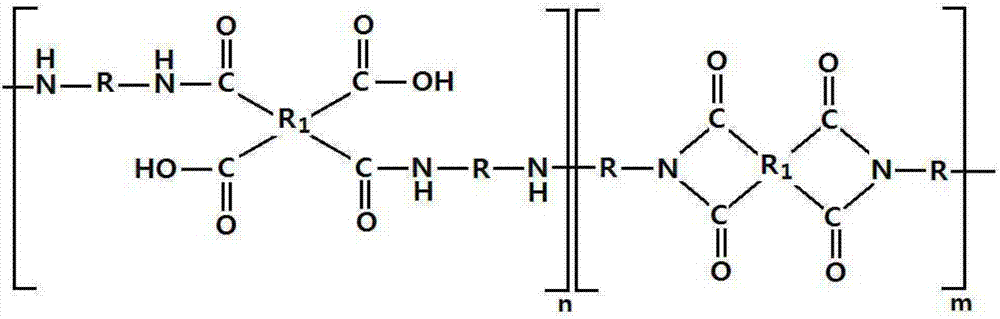

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: the manufacture of the polyimide polymer solution that is used to manufacture transparent polyimide film

[0045] While making nitrogen pass through a temperature-adjustable stirring reactor connected to a nitrogen injection device and a dropping funnel, after filling 704.2 g of DMAC at room temperature, make 32.02 g (0.1 mol) of TFMB as a fluorine-based diamine monomer to dissolve. 8.83 g (0.03 mol) of aromatic monomer BPDA and 31.1 g (0.07 mol) of fluorine monomer 6FDA were put and reacted as an acid anhydride monomer there. After 1 hour of complete dissolution, pyridine and acetic anhydride as a catalyst and a dehydrating agent were charged, heated to 70° C., reacted for 1 hour, and cooled to normal temperature.

[0046] Afterwards, the precipitate was solidified in a mixed solution of MeOH and distilled water (3:1). After fully washing in MeOH, it was fully dried in a vacuum oven at 80° C. for 6 hours to obtain a polyimide polymer solid.

[0047] Af...

Embodiment 2

[0056] Embodiment 2: the manufacture of transparent polyimide film

[0057] Utilize the applicator (applicator), with the wet film thickness of 400 μ m, the polyimide polymer solution obtained in the above-mentioned embodiment 1, comparative example 1 and comparative example 2 is coated on the glass substrate, then in convection oven (convection oven) was heated and dried to 280° C. to manufacture a polyimide film with a thickness of 30 μm.

Embodiment 3

[0058] Embodiment 3: the manufacture of the polyimide polymer solution that is used to manufacture colored polyimide film

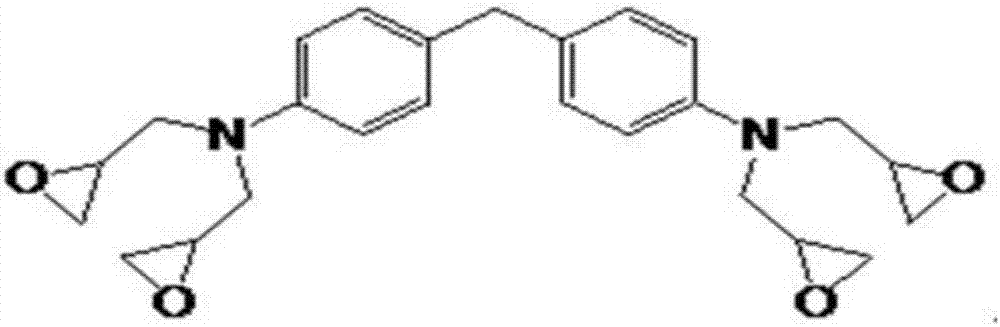

[0059]While making nitrogen pass through a temperature-adjustable stirred reactor connected to a nitrogen injection device and a dropping funnel, after filling 242.45 g of DMPA at room temperature, 10.91 g of PPDA was completely dissolved, and then 26.48 g of BPDA and 2.18 g of PMDA. After the complete dissolution and 1 hour later, 0.2 g of PA was injected and reacted for 16 hours to synthesize polyacrylamide (PA A, Polyacrylamide). Afterwards, 4,4'-methylenebis(N,N-diglycidylaniline) with a monomer (DMPA, BPDA and PMDA) content of 4000ppm was dissolved in the same solvent as the reaction solvent, and added to Mixing is carried out in the PAA at the end of the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com