Method For Producing Glass Plate Having Film

A manufacturing method and glass plate technology, which is applied in the direction of liquid chemical plating, coating, metal material coating process, etc., can solve the problems of image blackening, the situation where the user sees the electrode, etc., and achieve the goal of improving the adhesion of the film Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, this specific embodiment will be described based on the drawings.

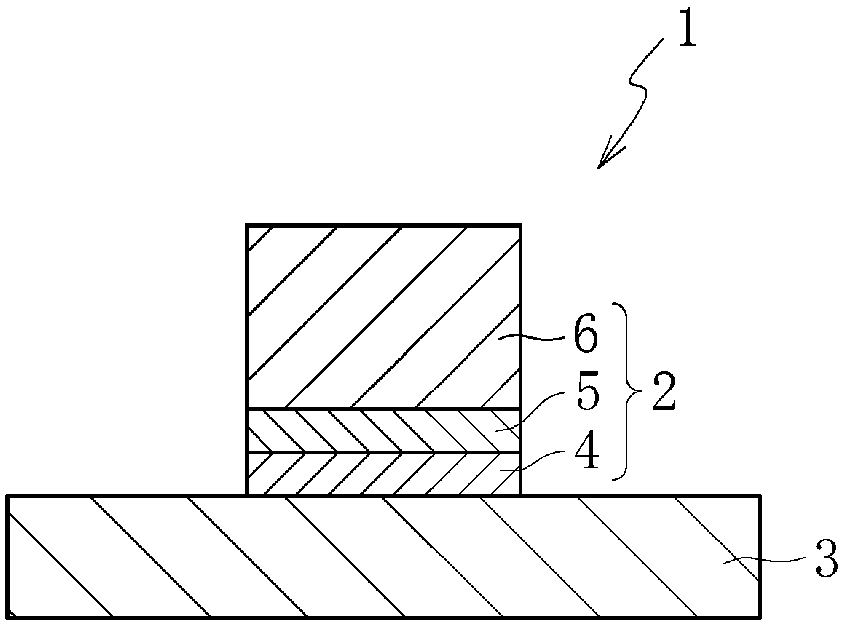

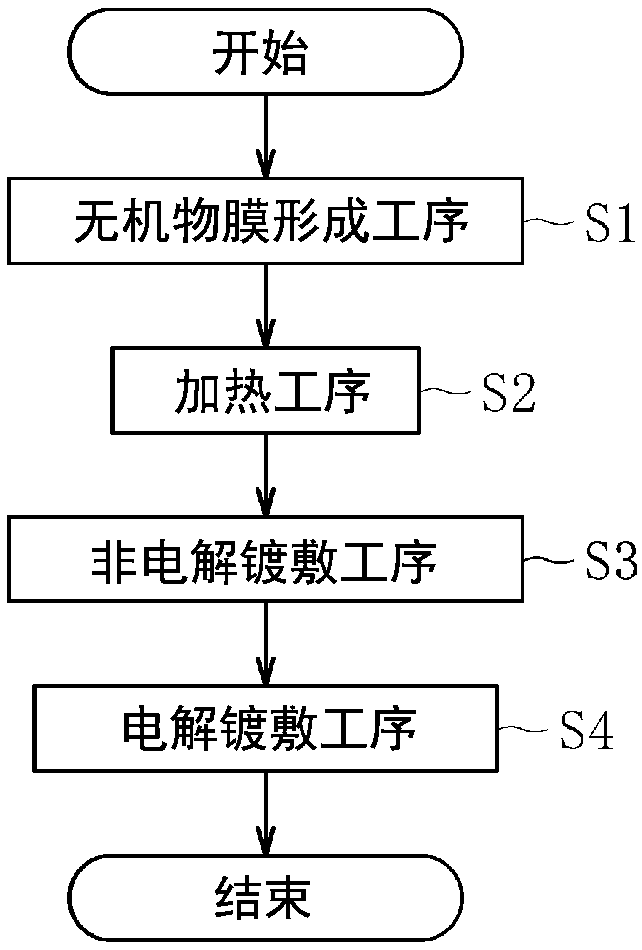

[0030] figure 1 It is a schematic cross-sectional view showing the film-coated glass plate according to the embodiment of the present invention. In this film-coated glass plate 1 , a laminated film 2 formed by laminating a plurality of films is formed on a glass plate 3 . The laminated film 2 includes: an inorganic film 4 containing at least a noble metal formed on a glass plate 3; and an electroless metal plating film 5 formed on the inorganic film 4 by electroless plating using the inorganic film 4 as a catalyst. , and the electrolytic plated metal film 6 formed by electrolytic plating on the electroless plated metal film 5 . In addition, the laminated film 2 is black when viewed from the side of the glass plate 3 . Examples of the noble metal contained in the inorganic film 4 include gold, silver, platinum, palladium, ruthenium, and the like.

[0031] The laminated film 2 of the film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com