Preparation method of insulated isolation coating suitable for high-temperature piezoelectric sensor

A technology of insulation isolation and high-temperature piezoelectricity, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of expensive equipment, high cost of film growth, and poor process compatibility, so as to improve stability and Accuracy, Achieve Part Integrity, High Film Cohesion Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

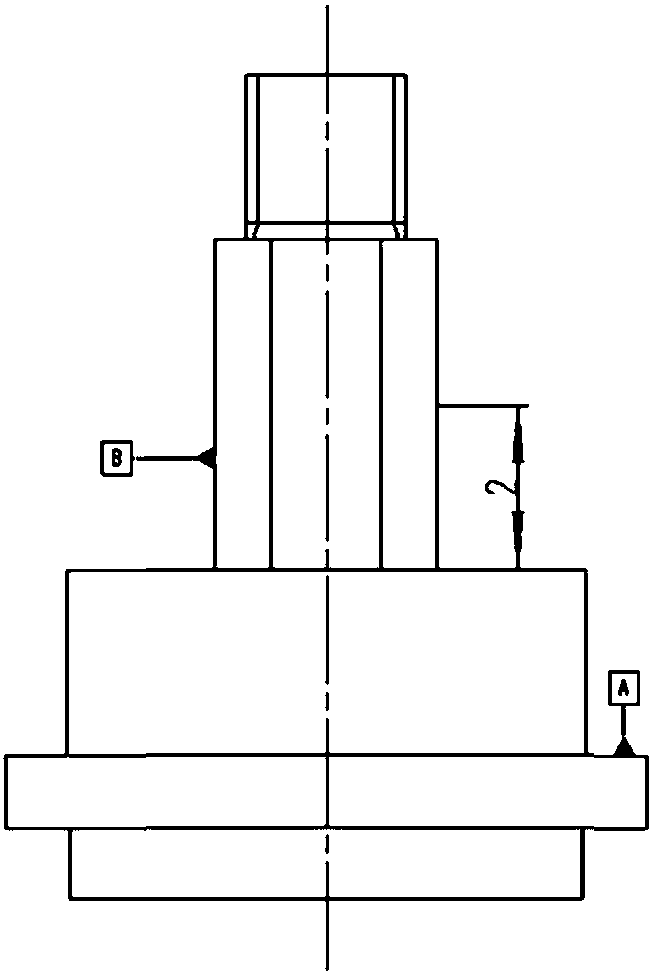

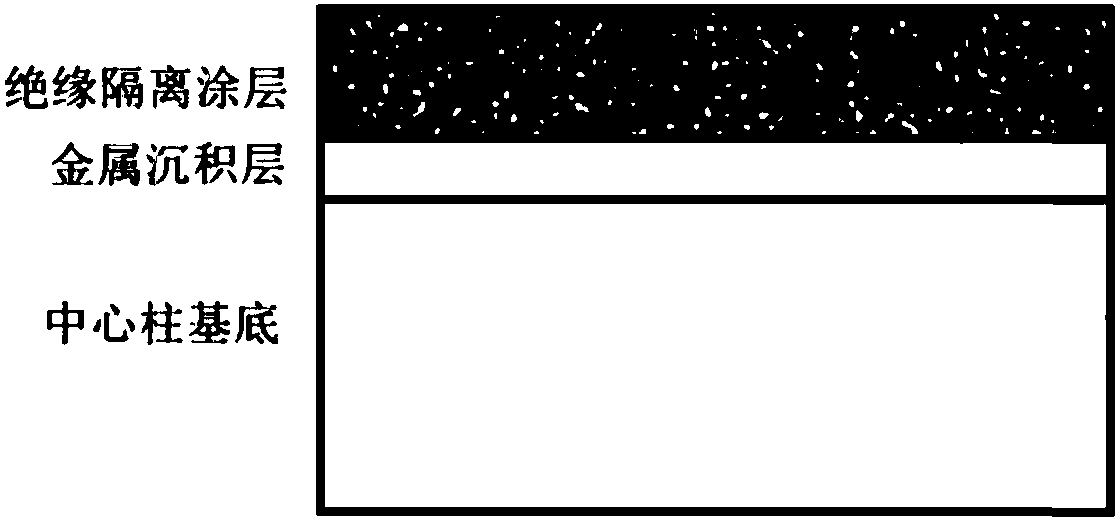

[0045] figure 1 It is the first embodiment of the present invention - a schematic diagram of the structure of the metal deposition layer / insulating isolation coating, which is the central support part of the piezoelectric sensor, and the manufacturing method includes the following steps:

[0046] Step 1. Pretreatment of central column

[0047] 1.1 gasoline ultrasonic cleaning for 15 minutes;

[0048] 1.2 Rinse with deionized water;

[0049] 1.3 Alcohol ultrasonic cleaning for 15 minutes;

[0050] 1.4 Ultrasonic cleaning with deionized water for 10 minutes;

[0051] 1.5 Dry with compressed air;

[0052] 1.6 Vacuum drying at 150°C for 120 minutes;

[0053] Step 2. Center column installation

[0054] The central column is assembled in the fixture of the deposition coating, and the part of the deposition coating is exposed, and the other parts are strictly protected by the cover of the tooling to prevent the deposition of the coating; then the central column and the tooling ...

Embodiment 2

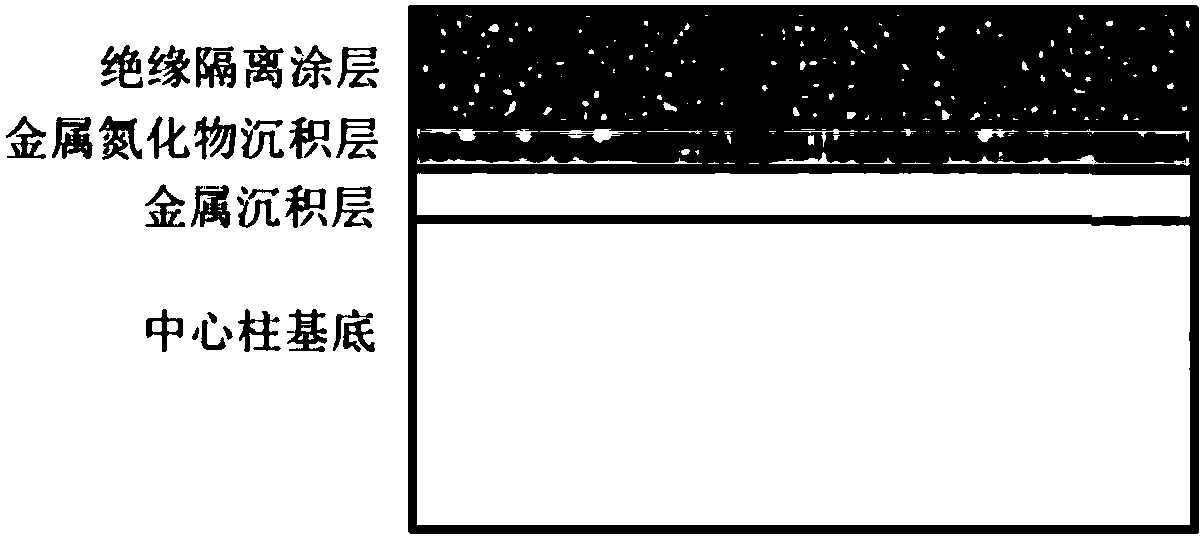

[0071] Embodiment 2: The difference between this embodiment and the specific embodiment 1 is that in step 5, the type of the transition layer is adjusted to be Al. Others are the same as in Example 1.

Embodiment 3

[0072] Embodiment 3: The difference between this embodiment and the specific embodiment 1 is that in step 5, the type of the transition layer is adjusted to be Cr. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com