Magnesium base composite material

a composite material and magnesium base technology, applied in the direction of metal silicides, etc., can solve the problems of increasing energy consumption and cost, and achieve the effect of improving mechanical properties, improving mechanical properties, and improving the reaction between mg and si

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

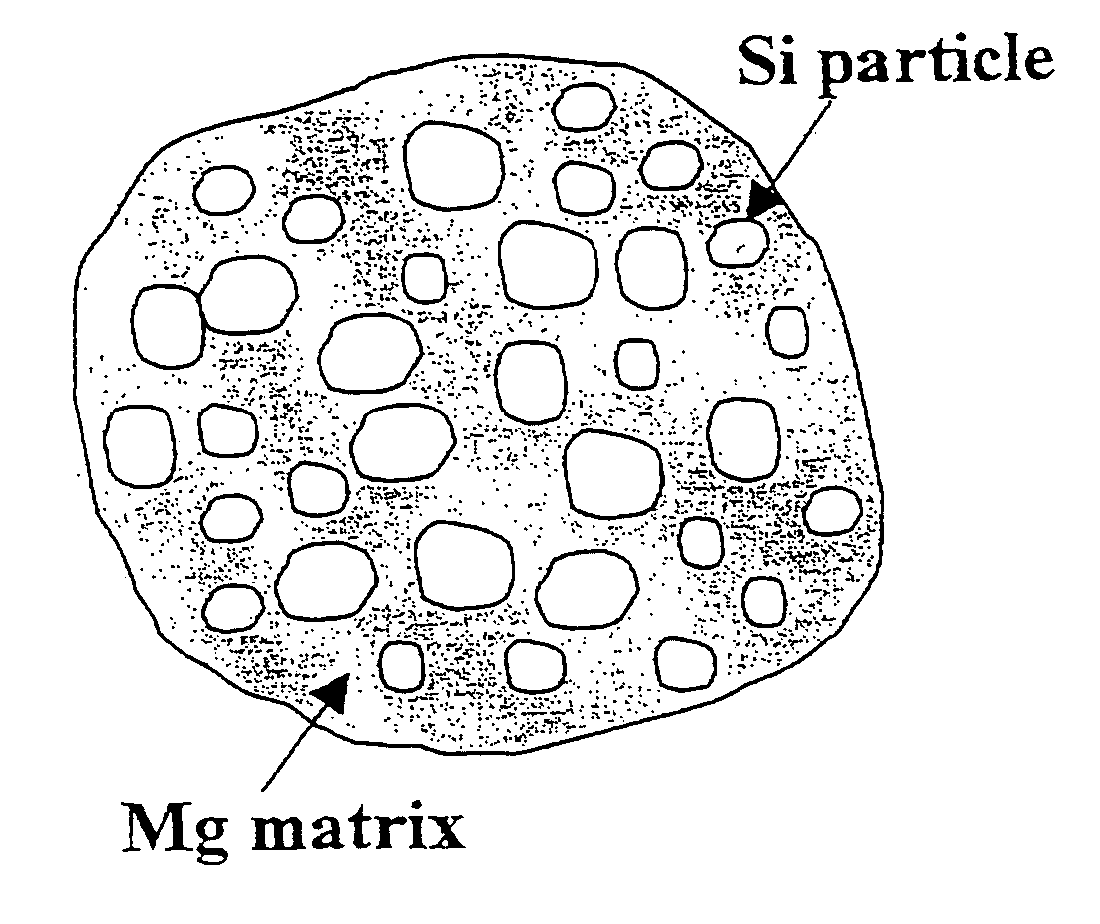

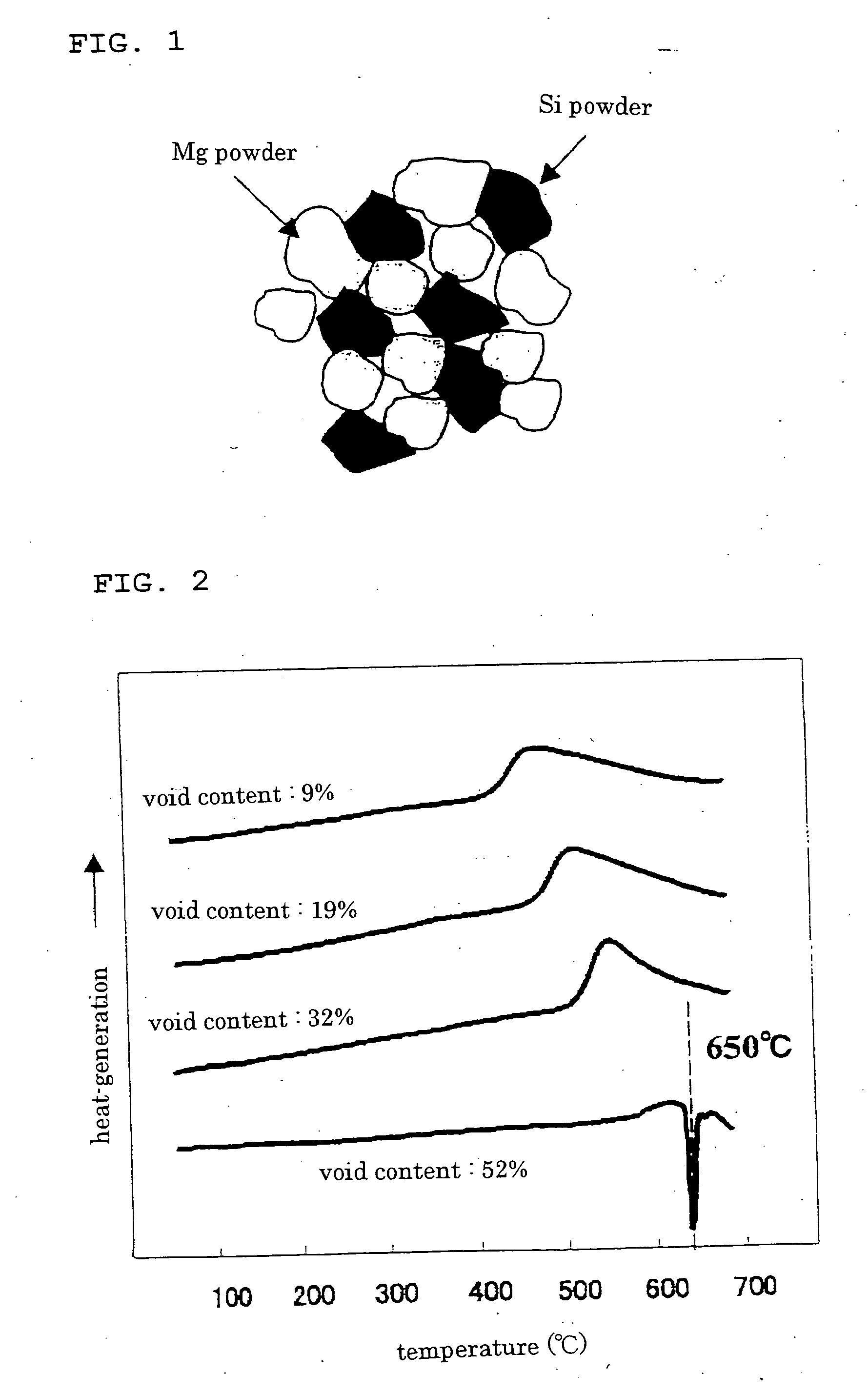

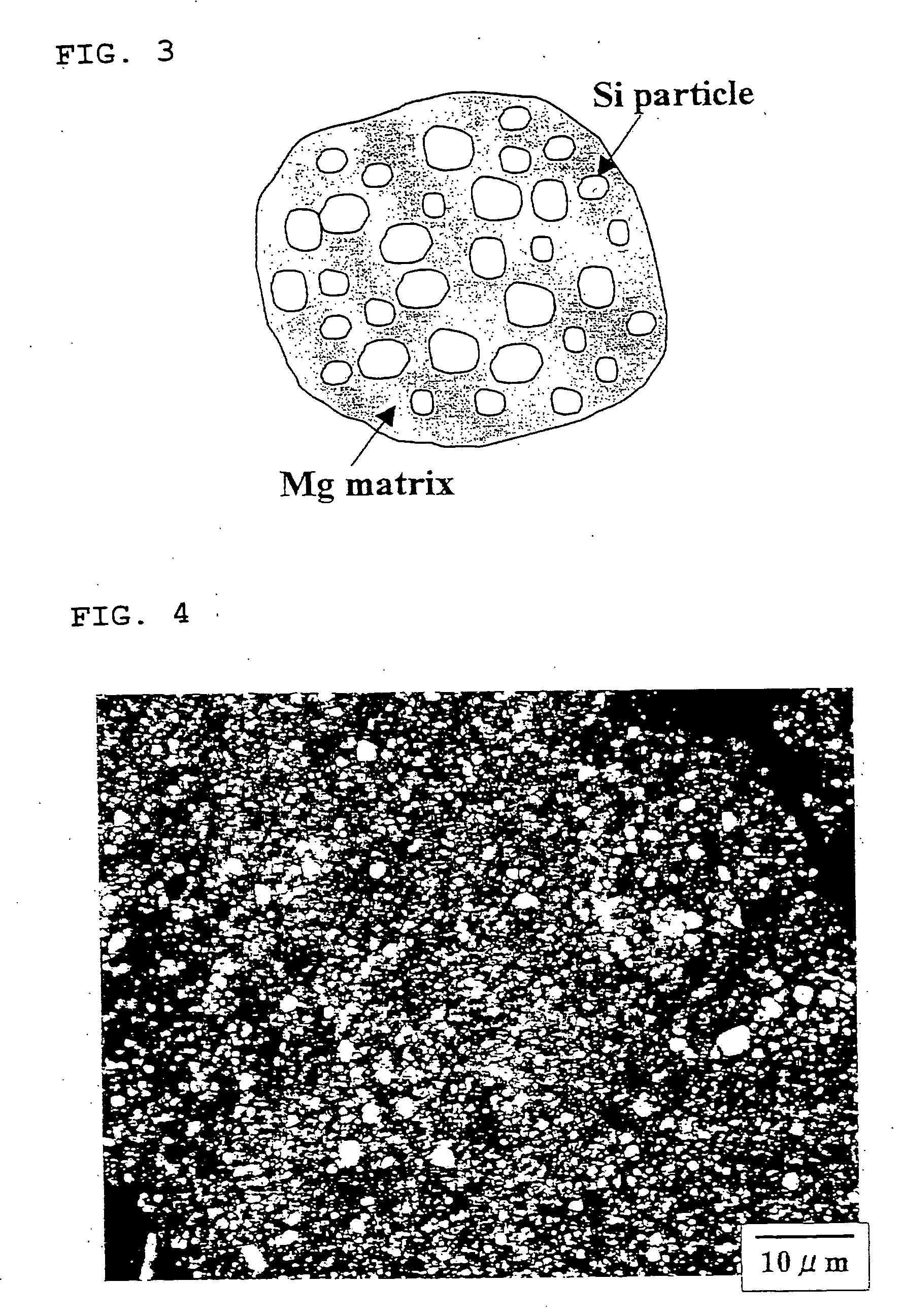

[0254] As starting materials, 90 parts by weight of pure Mg powder (average particle size: 112 μm) and 10 parts by weight of Si powder (average particle size: 64 μm) were prepared. After blending these, the resulting material was evenly mixed by a ball mill to obtain mixed powder. A circular metal mold having a diameter of 34 mm was filled with the resulting mixed powder, and a load having a face pressure of 2 to 7 t / Cm2 was applied thereto, thereby forming compressed powder molded bodies A-1 to A-7.

[0255] In a separated manner from the compressed powder molded bodies A-1 to A-7, the following tubular furnace was prepared. In other words, the tubular furnace in which nitrogen gas (gas flow rate: 3 dm3 / min) was allowed to flow, with the inner temperature thereof being controlled to 580° C., was prepared. Each of the compressed powder molded bodies A-1 to A-7, obtained as described above, was inserted into the tubular furnace, and after having been heated and maintained for 15 minute...

example 2

[0267] As starting materials, 85 parts by weight of AZ91D magnesium alloy powder (average particle size: 61 μm; nominal composition: Mg-9A1-1Zn / mass %) and 15 parts by weight of Si powder (average particle size: 64 μm) were prepared. After blending these, the resulting material was evenly mixed by a ball mill to obtain mixed powder. A circular metal mold having a diameter of 11.3 mm was filled with the resulting mixed powder, and a load having a face pressure of 5 t / cm2 was applied thereto, thereby forming a compressed powder molded body A-8. The void content thereof was measured to find that it showed 12.3%, which satisfied the range defined by the present invention.

[0268] The compressed powder molded body A-8, obtained as described above, was inserted into a tubular furnace through which nitrogen gas (gas flow rate: 2 dm3 / min) was allowed to flow, and after having been heated at the respective heating temperatures shown in Table 2 for 30 minutes, and maintained, this was cooled t...

example 3

[0271] Pure Mg powder (average particle size: 112 μm) and Si powder (average particle size: 64 μm) were prepared as starting materials, and the two materials were mixed so as to have a blended composition as shown in Table 3, thereby obtaining mixed powder. A circular metal mold having a diameter of 11.3 mm was filled with the resulting mixed powder, and a load having a face pressure of 6 t / cm2 was applied thereto, thereby forming green compact molded bodies A-9 to A-15 The void contents of these molded bodies A-9 to A-15 were measured to obtain values of 8.9 to 11%, each of which satisfies the range defined by the present invention.

[0272] Each of the compressed powder molded bodies A-9 to A-15, obtained as described above, was inserted into a tubular furnace through which nitrogen gas (gas flow rate: 2 dm3 / min) was allowed to flow, with the temperature inside thereof being controlled to 580° C., and after having been heated and maintained for 15 minutes, this was cooled to normal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com