Method for making magnesium-based composite material and equipment for making the same

a magnesium-based composite material and magnesium-based alloy technology, applied in the field of magnesium-based composite material manufacturing and equipment, can solve the problems of inability to achieve toughness and strength of magnesium-based alloys, prone to aggregation, and nano-scale reinforcements added to metal or alloy melts,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

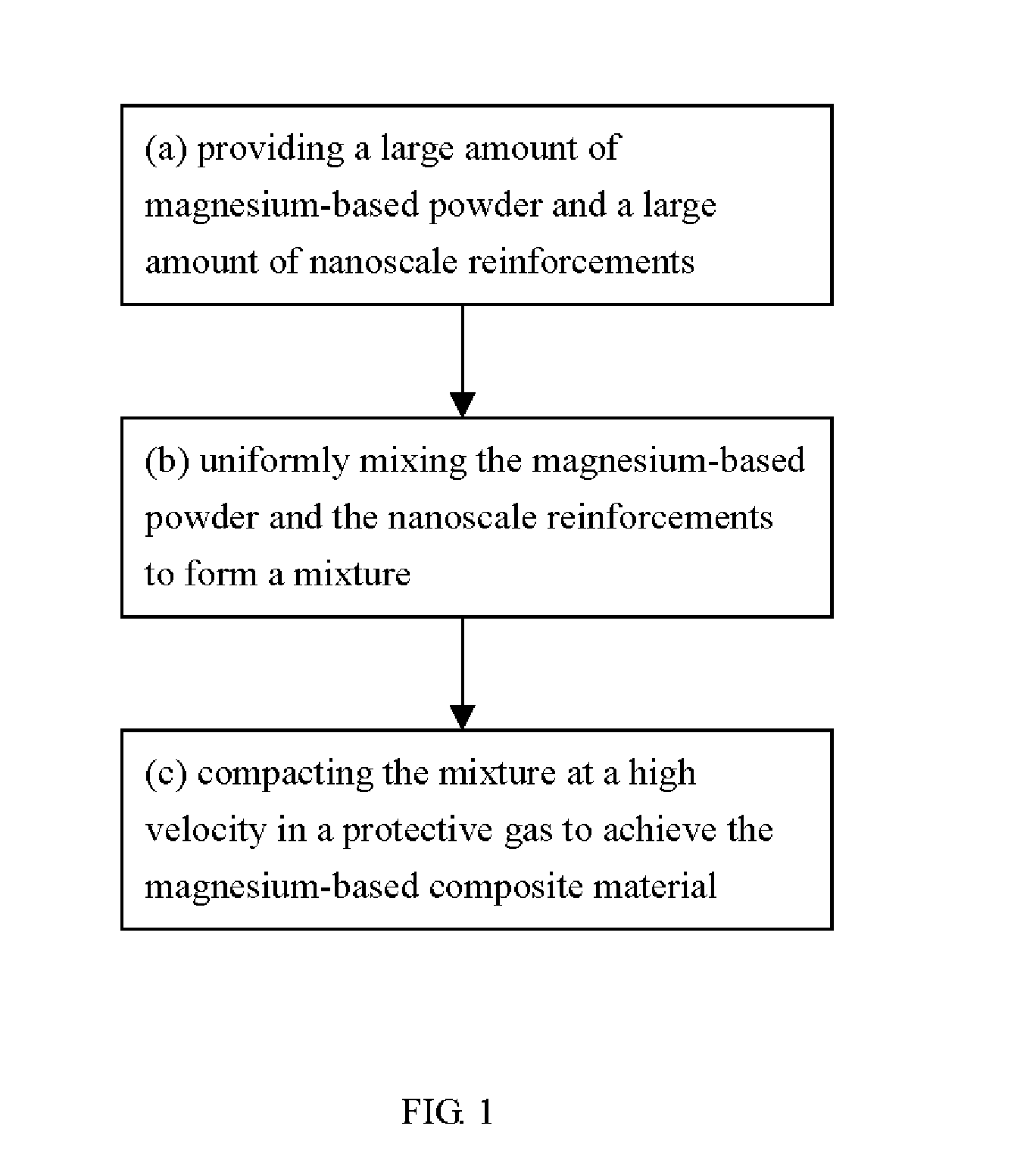

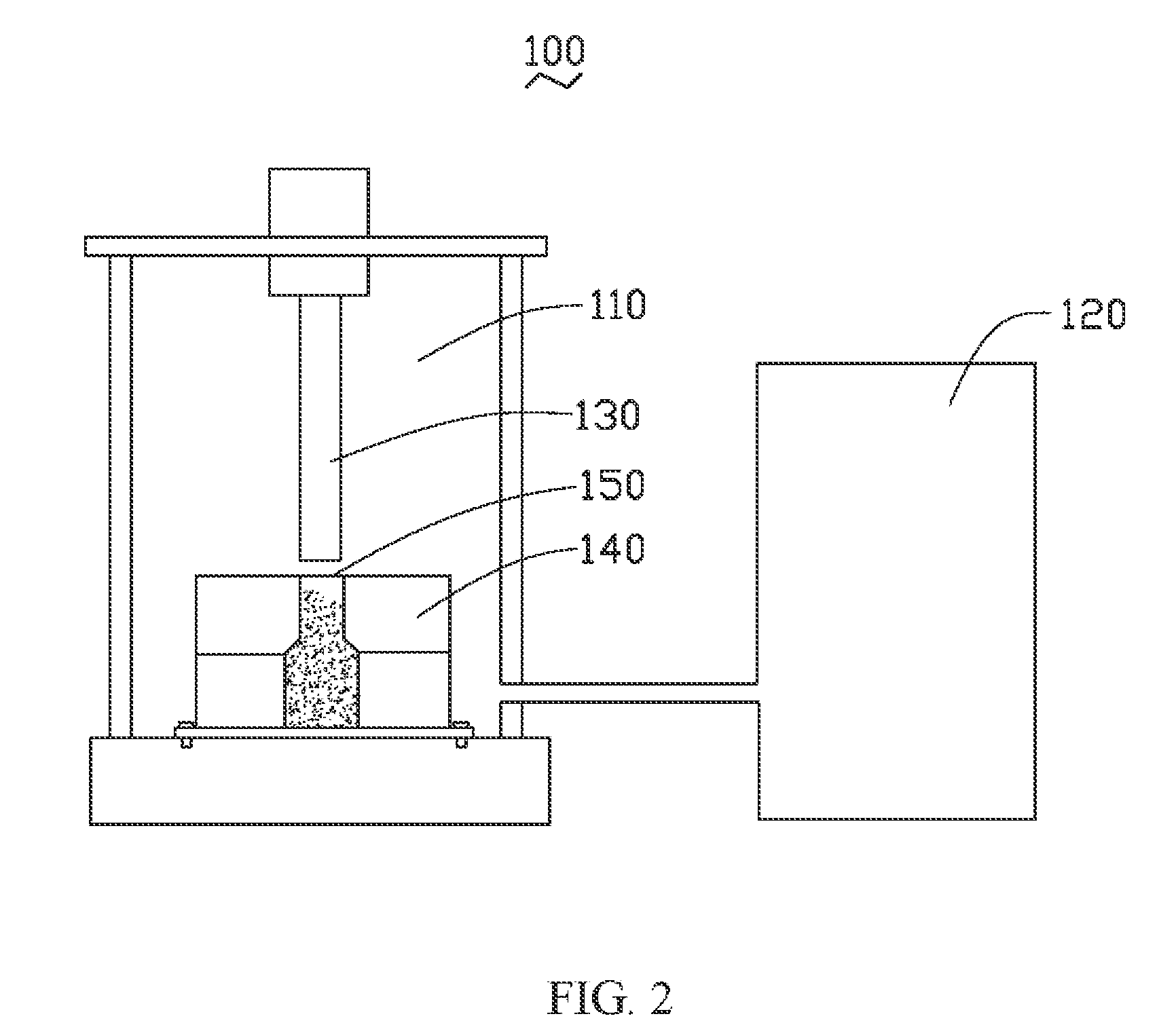

[0013]Reference will now be made to the drawings to describe, in detail, embodiments of the present method for fabricating the magnesium-based composite material and the equipment for fabricating the same.

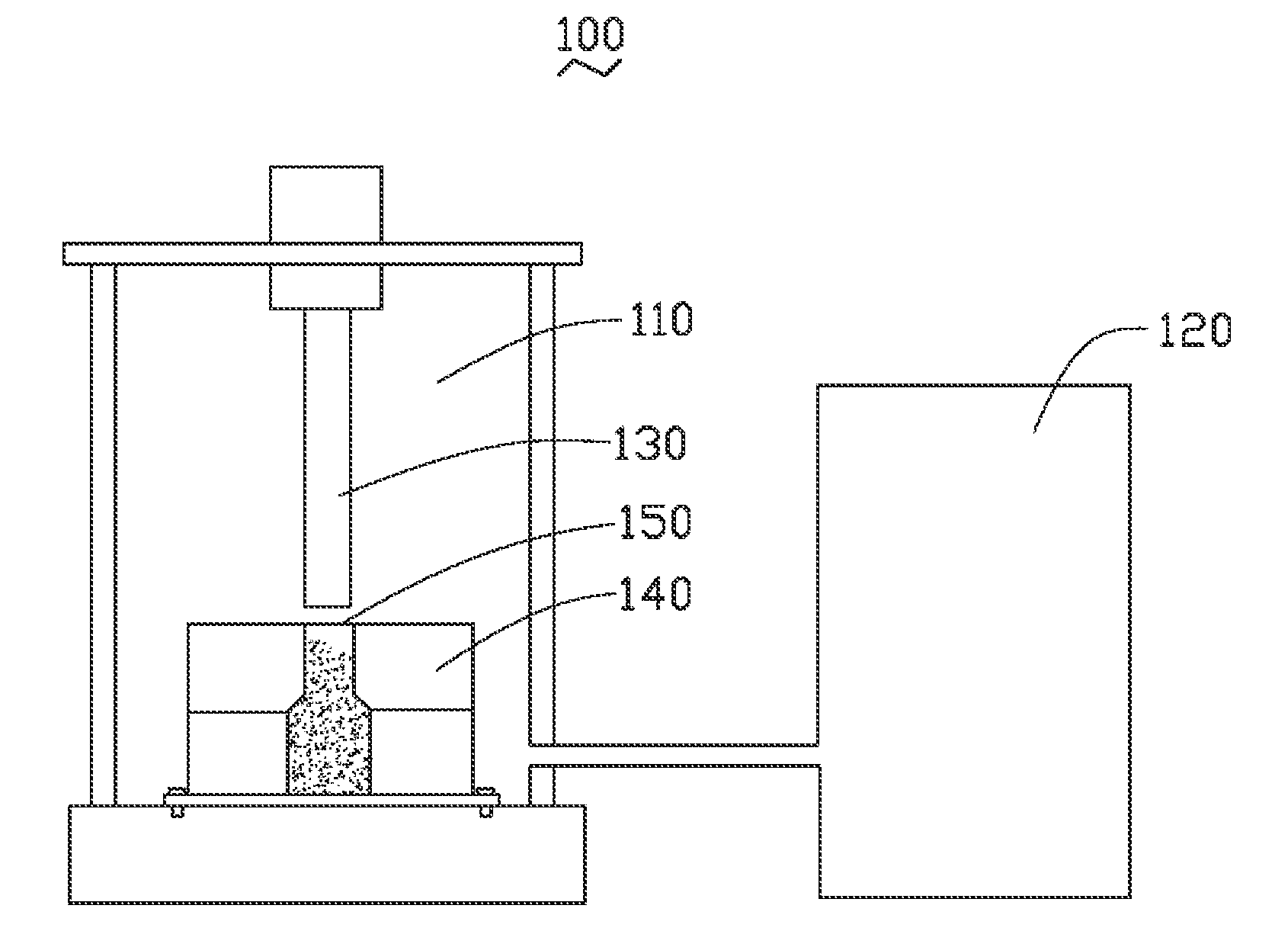

[0014]Referring to FIG. 1, a method for fabricating a magnesium-based composite material includes the steps of: (a) providing a large amount of magnesium-based powder and a large amount of nanoscale reinforcements; (b) uniformly mixing the magnesium-based powder and the nanoscale reinforcements to form a mixture; and (c) compacting the mixture at a high velocity in a protective gas to achieve the magnesium-based composite material.

[0015]In step (a), the material of the magnesium-based powder can, beneficially, be pure magnesium or magnesium-based alloys. Components of the magnesium-based alloys include magnesium and other elements selected from a group consisting of zinc (Zn), manganese (Mn), aluminum (Al), thorium (Th), lithium (Li), silver, calcium (Ca), and any combination there...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com