Silicon carbide particle reinforced magnesium-based composite material and preparation method

A technology for silicon carbide particles and composite materials, which is applied in the preparation and preparation of silicon carbide particle-reinforced magnesium-based composite materials by a multi-directional forging method, and the field of silicon carbide particle-reinforced magnesium-based composite materials and preparation, can solve problems such as low density and achieve Excellent mechanical properties, good mechanical properties, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

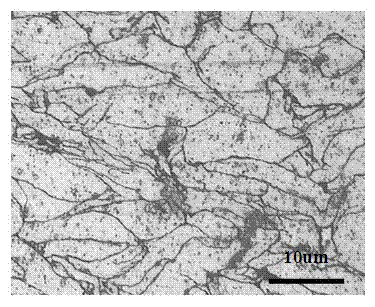

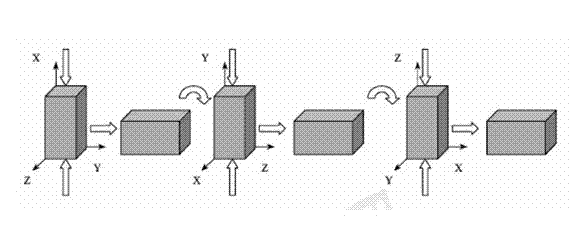

[0017] A mixed powder in which Mg powder, Al powder and SiC particle powder are mixed is prepared. Wherein the mass percentage of Al powder is 5%, and the mass percentage of SiC particle powder is 5%. The mixed powder was mixed under nitrogen protection for 20min, and then pressed to a density of 1.74g / cm 3 The powder green body is subjected to pressureless sintering at 500°C under vacuum conditions, and the resulting product is the SiC particle-reinforced magnesium-based composite green body. The sintered SiC particle-reinforced magnesium-based composite green body is subjected to multi-directional forging three times on a forging press.

[0018] Density (g / cm 3 ) Hardness / HB σb (MPa) 1.85 52 165.4

Embodiment approach 2

[0020] A mixed powder in which Mg powder, Al powder and SiC particle powder are mixed is prepared. Wherein the mass percentage of Al powder is 7%, and the mass percentage of SiC particle powder is 10%. The mixed powder was mixed under nitrogen protection for 20min, and then pressed to a density of 1.78g / cm 3 The powder green body is subjected to pressureless sintering at 500°C under vacuum conditions, and the resulting product is the SiC particle-reinforced magnesium-based composite green body. The sintered SiC particle-reinforced magnesium-based composite green body is subjected to multi-directional forging three times on a forging press.

[0021] Density (g / cm 3 ) Hardness / HRF σb(MPa) 1.95 55.7 196.4

Embodiment approach 3

[0023] A mixed powder in which Mg powder, Al powder and SiC particle powder are mixed is prepared. Wherein the mass percentage of Al powder is 10%, and the mass percentage of SiC particle powder is 15%. The mixed powder was mixed under nitrogen protection for 20min, and then pressed to a density of 1.92g / cm 3 The powder green body is subjected to pressureless sintering at 500°C under vacuum conditions, and the resulting product is the SiC particle-reinforced magnesium-based composite green body. The sintered SiC particle-reinforced magnesium-based composite green body is subjected to multi-directional forging three times on a forging press.

[0024] Density (g / cm 3 ) Hardness / HRF σb (MPa) 2.01 60 175.3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com