Graphene enhanced magnesium-based composite and preparing method thereof

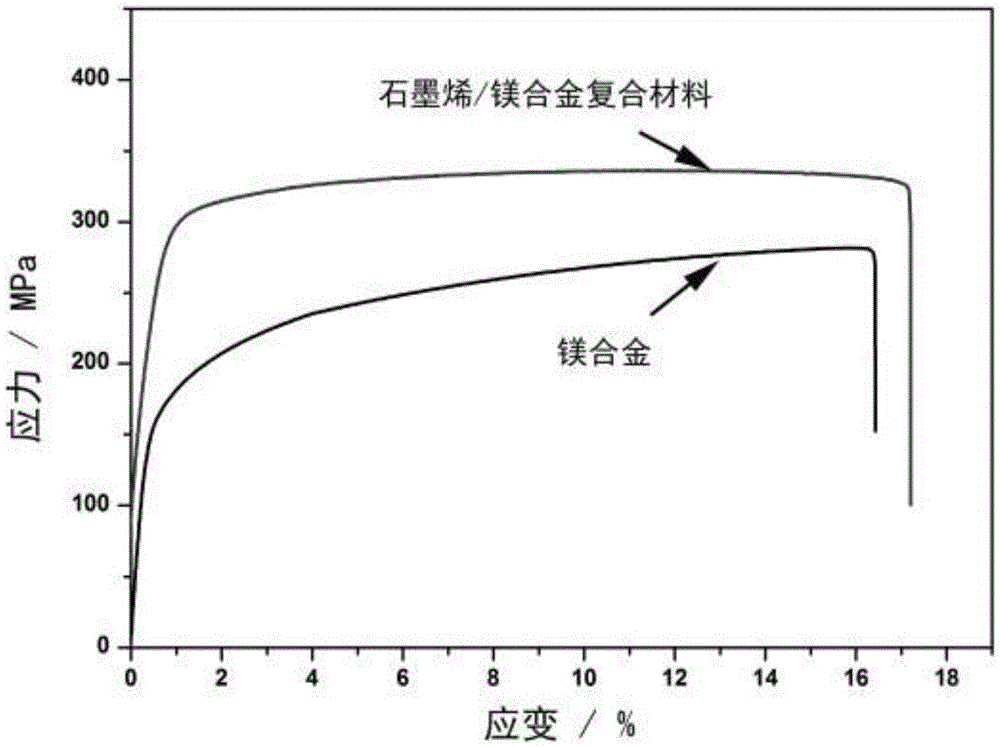

A composite material and graphene technology, which is applied in the field of graphene-reinforced magnesium-based composite materials and its preparation, can solve the problems of unfriendly environment, difficult to remove impurities, impurity elements, etc., achieve simple process flow, wide application prospects, and improve mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The technique of the graphene reinforced pure magnesium-based composite material of the present embodiment is carried out in the following steps:

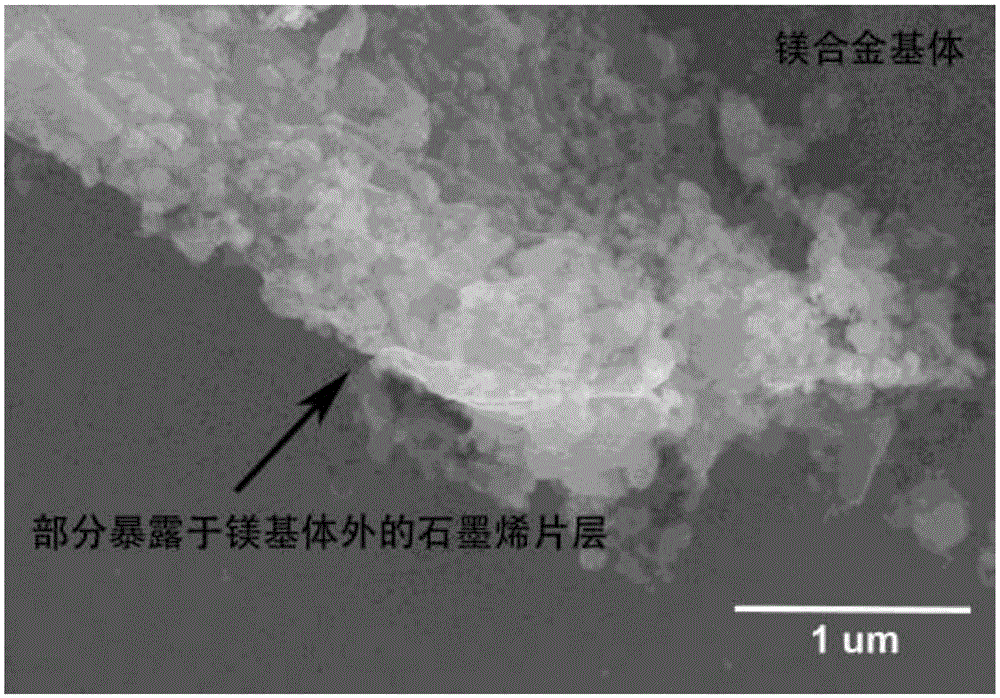

[0024] (1) Graphene powder 30g with a sheet size of 100 μm is mixed with 470 g of pure magnesium particles with a particle size of 50 μm for 30 min by ball milling. The ball milling process is carried out under an argon atmosphere, and the material of the ball mill jar is an agate jar. The ball milling speed is 600rpm; the mass fraction of graphene in the mixed powder is 6wt.%, and the ball-to-material ratio is 15:1;

[0025] (2) Place the mixed powder obtained by ball milling in step (1) in an ethanol solvent for ultrasonic dispersion with a power of 200W and a time of 120min, accompanied by mechanical stirring; subsequently, the resulting mixed solution is stirred and heated to remove the solvent and Vacuum drying, stirring and heating temperature is 35°C, vacuum drying temperature is 35°C, stirring rate is 600rpm, to obta...

Embodiment 2

[0029] The technique of the graphene reinforced Mg-Zn series magnesium-based composite material of the present embodiment is carried out in the following steps:

[0030] (1) 0.8 g of graphene powder with a sheet size of 80 μm and 799.2 g of pure magnesium particles with a particle size of 30 μm were ball milled for 60 minutes. The ball milling process was carried out under an argon atmosphere, and the material of the ball mill was agate. tank, the ball milling speed is 400rpm; the mass fraction of graphene in the mixed powder is 0.1wt.%, and the ball-to-material ratio is 2:1;

[0031] (2) Place the mixed powder obtained by ball milling in step (1) in an ethanol solvent for ultrasonic dispersion with a power of 400W and a time of 60min, accompanied by mechanical stirring; subsequently, the resulting mixed solution is stirred and heated to remove the solvent and Vacuum drying, stirring and heating temperature is 35°C, vacuum drying temperature is 35°C, stirring rate is 400rpm, t...

Embodiment 3

[0035] The technique of the graphene reinforced Mg-Al series magnesium-based composite material of the present embodiment is carried out in the following steps:

[0036] (1) Graphene powder 5g with a sheet size of 20 μm is mixed with 495 g of pure magnesium particles with a particle size of 10 μm for 180 min by ball milling. The ball milling process is carried out under an argon atmosphere, and the material of the ball mill jar is an agate jar. The ball milling speed is 200rpm; the mass fraction of graphene in the mixed powder is 1wt.%, and the ball-to-material ratio is 8:1;

[0037] (2) Place the mixed powder obtained by ball milling in step (1) in an ethanol solvent for ultrasonic dispersion with a power of 800W and a time of 15min, accompanied by mechanical stirring; subsequently, the resulting mixed solution is stirred and heated to remove the solvent and Vacuum drying, stirring and heating temperature is 55°C, vacuum drying temperature is 55°C, stirring rate is 200rpm, to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com