Preparation method of high-performance graphene nanosheet reinforced magnesium matrix composite

A technology of graphene nanosheets and composite materials, which is applied in the field of preparation of graphene nanosheets reinforced magnesium-based composite materials, can solve problems such as poor wettability and uneven dispersion, achieve improved mechanical properties, simple process, and solve the problem of wetting poor sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

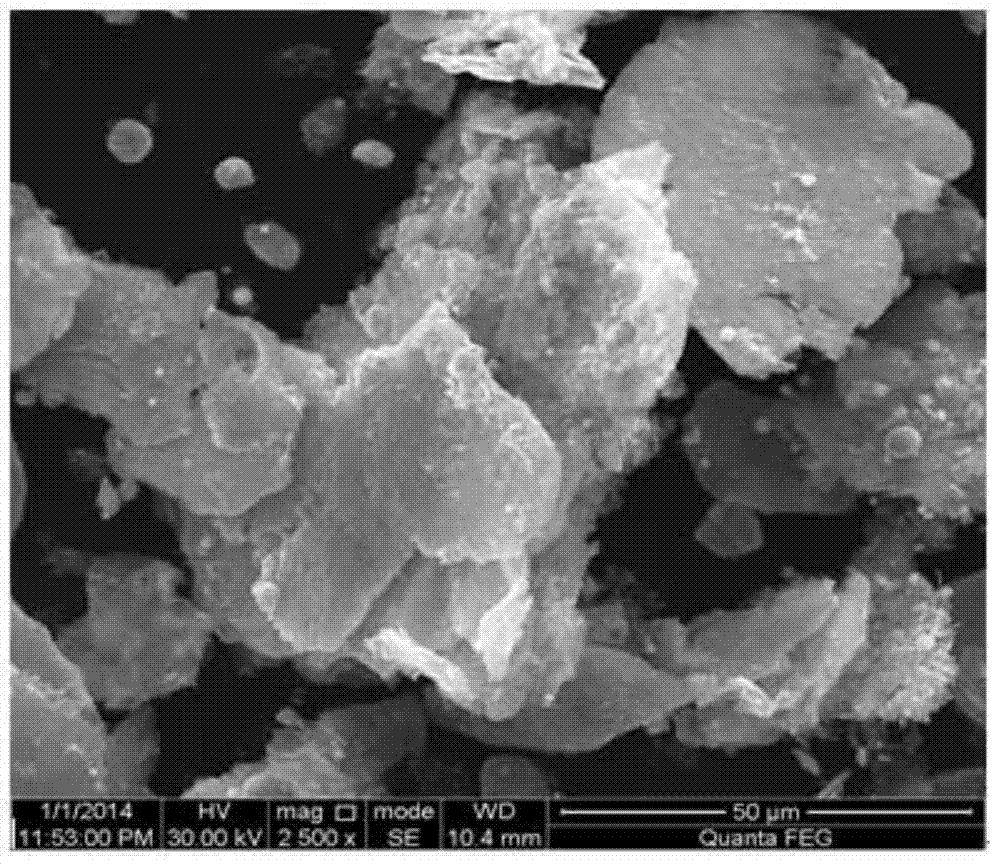

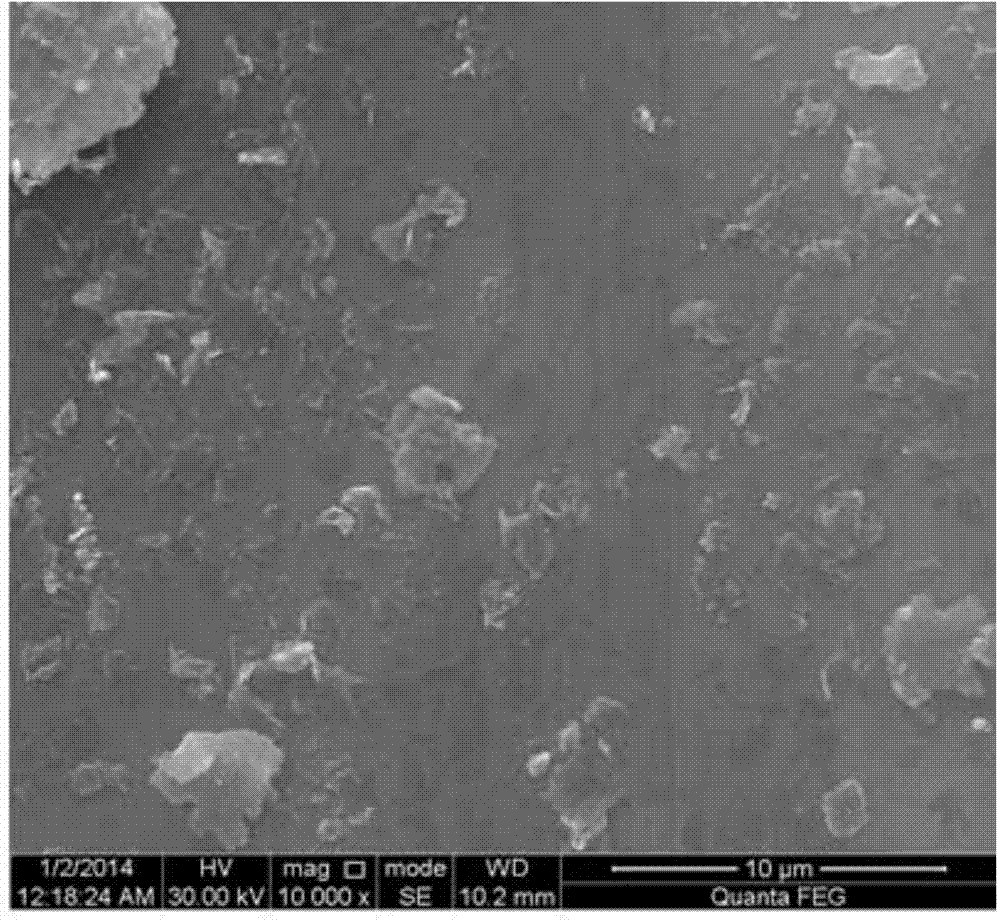

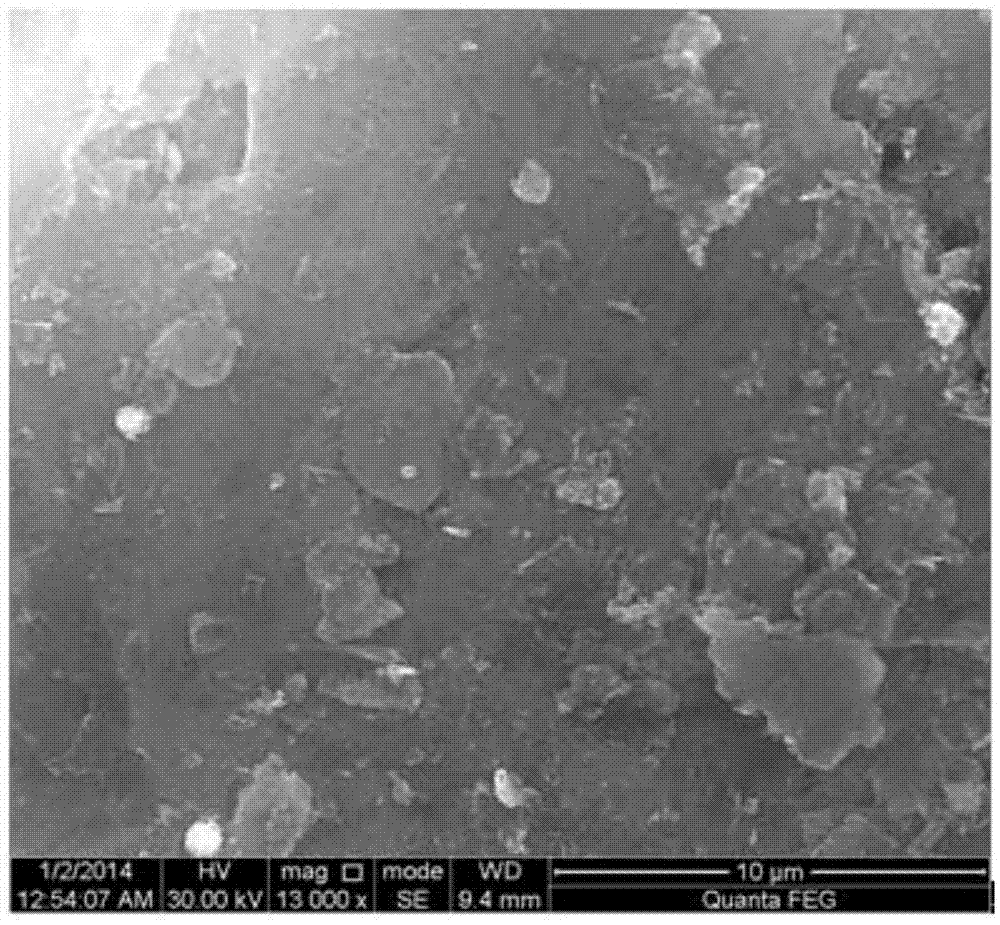

[0018] Specific embodiment one: the preparation method of the high-performance graphene nanosheet reinforced magnesium-based composite material of this embodiment is carried out according to the following steps:

[0019] 1. Mix graphene nanosheets and Zn powder, and ball mill at a speed of 250r / min to 450r / min for 6h to 12h to obtain a GnpZn composite powder, wherein the mass ratio of Zn powder to Gnp in the GnpZn composite powder is 10 to 15: 1;

[0020] 2. Add the composite powder obtained in step 1 into the Mg-Zn alloy melt, and stir at 530°C-630°C for 10min-20min, wherein the mass fraction of Zn in the Mg-Zn alloy melt is 2%-6%, The mass fraction of Gnp in the mixed alloy melt is 0.3% to 3%;

[0021] 3. Raise the temperature of the mixed alloy melt obtained in step 2 to 650°C-750°C, and then perform ultrasonic treatment, the ultrasonic power is 500w-800w, and the ultrasonic time is 5min-10min;

[0022] 4. Pouring the mixed melt after ultrasonic treatment in step 3 into a...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that: the mass ratio of Zn powder to Gnp in the GnpZn composite powder described in step 1 is 10˜13.5:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the ball mill described in step 1 uses steel balls and steel ball tanks, and the mass ratio of balls to materials is 8-15:1. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com