SiC particle-containing magnesium alloy high in elastic modulus and preparation method of magnesium alloy

A particle and intermediate alloy technology, applied in the field of high elastic modulus magnesium matrix composite materials, can solve the problems of poor resistance to elastic deformation, low elastic modulus of alloys, and low elastic modulus, and achieve good plasticity and high elastic modulus. , The effect of processing and manufacturing is easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0091] According to the present invention, a method for preparing the above-mentioned high elastic modulus magnesium-based composite material is further provided, comprising the following steps:

[0092] 1) Drill holes on the pure magnesium ingot, the diameter of the holes is 2.0-2.5cm; carry out surface modification treatment on SiC particles, put them into the holes after drying to obtain β-SiC p Granular pure magnesium ingot;

[0093] 2) Melting and casting: Put the pure magnesium ingot with SiC particles into an iron crucible and heat it to 700-720°C under the protective atmosphere of Ar gas. 740°C, then add the remaining components and stir to control the complete melting of the master alloy until the casting time is less than or equal to 3 minutes, refining and removing slag, and casting to obtain an ingot.

[0094] In the above method, each component is selected according to the designed high-modulus magnesium-based composite material component distribution ratio. In t...

Embodiment 1

[0099] Embodiment 1, preparation and performance identification of magnesium-based composite material of the present invention

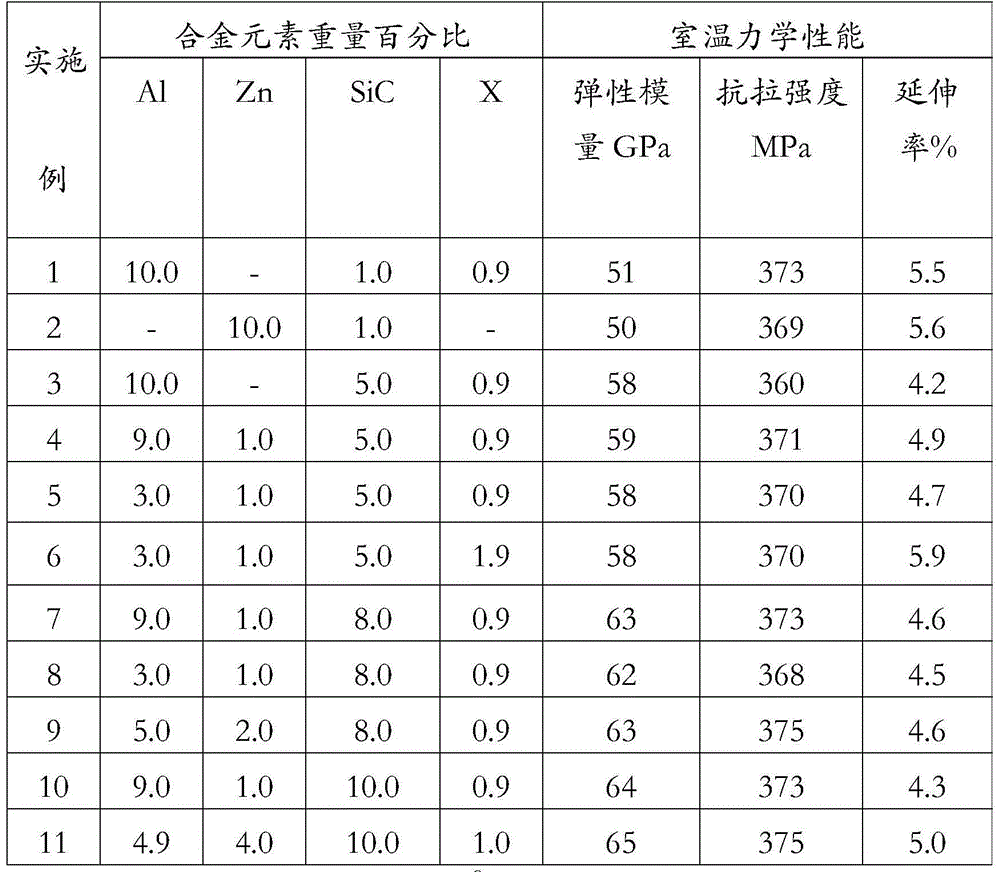

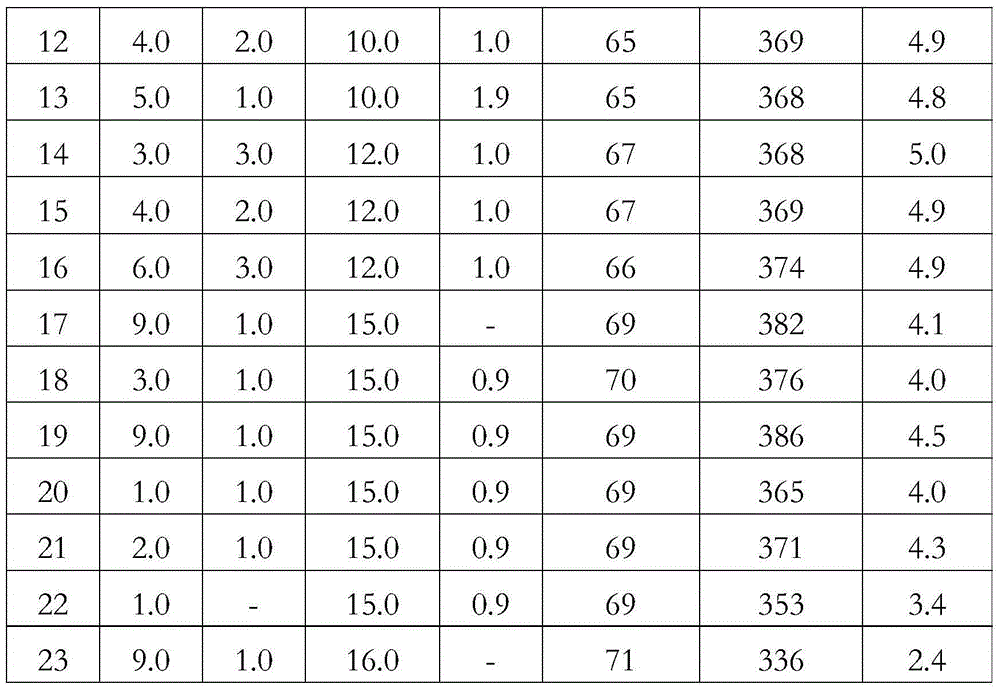

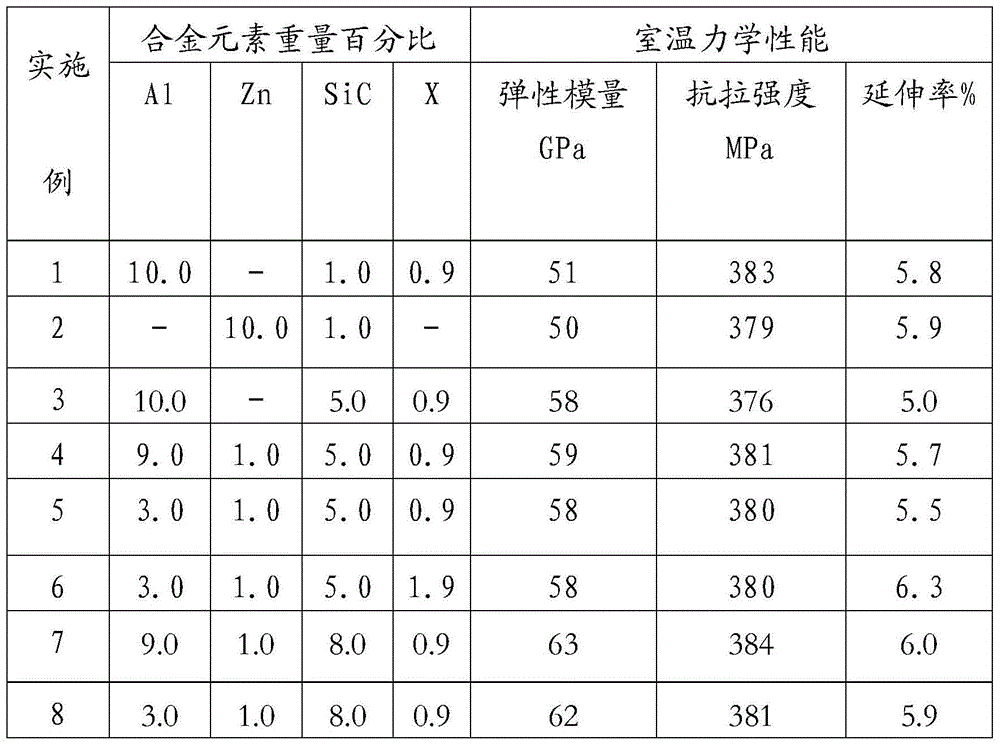

[0100] In the examples of the present invention, composite materials were prepared respectively according to the component distribution ratios shown in Table 1-Table 4, and the specific preparation methods are as follows:

[0101] 1. Take each component according to the designed high elastic modulus magnesium-based composite component distribution ratio, among which: Mg is added in the form of pure magnesium, and SiC particles are added in the form of β-SiC p Add in the form of particles (with a particle size of 1.0-20 μm), Zn is added in the form of pure zinc, and the rest of the components are added in the form of magnesium-based master alloys;

[0102] 2. Drill holes on pure magnesium ingots, the diameter of the holes is 2.0-2.5cm; for β-SiC p The particles were subjected to surface modification treatment, dried and put into the holes; the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com