A kind of preparation method of rare earth carbonate that does not produce ammonia nitrogen wastewater

A technology for rare earth carbonate and ammonia nitrogen wastewater, applied in the fields of rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of large consumption of chemicals, high cost of treatment chemicals, and the impossibility of effluent reaching the national first-level or second-level discharge standards and other problems, to achieve the effect of easy washing of impurities and improving the utilization rate of rare earth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

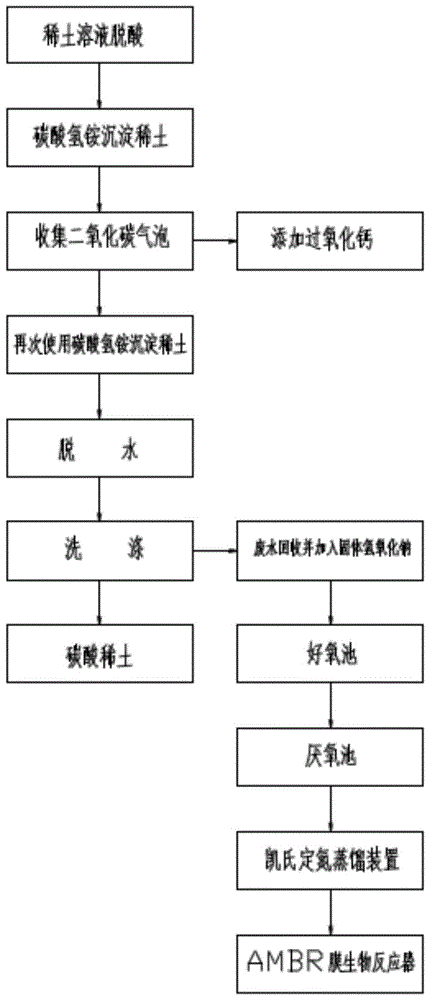

[0019] The working principle of this implementation is very simple, a method for preparing rare earth carbonate that does not produce ammonia nitrogen wastewater, the steps are as follows:

[0020] (1) prepare rare earth solution, measure acidity by pH-3C acidity meter, if the acidity is too high, rare earth feed liquid is placed in the heating container, under the condition of ventilating, heat, the dehydration moisture of rare earth feed liquid reaches 50%, ensure Stop heating when excess acid has evaporated;

[0021] (2) Put the deacidified rare earth solution in a special stirring container, and add ammonium bicarbonate as a precipitant;

[0022] (3) Collect the discharged carbon dioxide, add calcium peroxide in the carbon dioxide container, eliminate carbon dioxide bubbles, release oxygen and generate water;

[0023] (4) Use ammonium bicarbonate as a precipitant again, keep the temperature at 25°C ± 1°C, until the pH value of the clear liquid is 7.0-8.0, go through a deh...

Embodiment 1

[0030] (1) Take 1.5 grams of pure rare earth oxide and dissolve it in acid, measure the acidity by pH-3C acidity meter, heat it to 80 degrees with 1M HO340ML, and stop deacidification after one hour.

[0031] (2) Taking the volume unit as a reference, mix and stir the rare earth solution and ammonium bicarbonate at a ratio of 10:1, and add ammonium bicarbonate dropwise to the rare earth solution every five minutes.

[0032] (3) When a large amount of carbon dioxide bubbles are generated, collect the carbon dioxide bubbles, add corresponding calcium peroxide into the carbon dioxide collection tube, and react to generate water and oxygen.

[0033] (4) Ammonium bicarbonate is used again to precipitate rare earths, and the pH value is reduced to increased. When the pH value is 7.0-8.0, the formation of crystal nuclei is fast.

[0034] (5) The precipitate is dehydrated and washed for 15 minutes to obtain rare earth carbonate.

[0035] (6) Recover the waste water left after washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com