Method for clean preparation H acid

A clean, sulfuric acid technology, applied in the preparation of sulfonic acid, organic chemistry, etc., can solve the problem of large waste water discharge, achieve the effects of reducing waste acid discharge, improving utilization, and reducing production and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

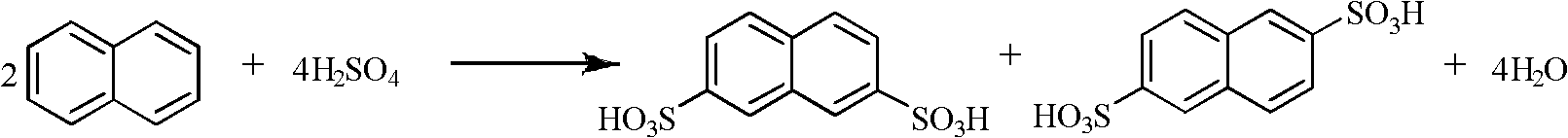

[0045] Step 1: Sulfonation

[0046] Add 480 kg of concentrated sulfuric acid into a 500 liter reaction kettle, add 128 kg of refined naphthalene under stirring, slowly raise the temperature to 177-181°C, keep the temperature for 5 hours, then slowly cool down to 50°C, and control the temperature of the reaction solution to 50°C ~60°C, slowly drop 109 liters of water into the reaction solution, dilute the sulfonation reaction solution, and keep stirring at 60°C for 1 hour, filter and separate 2,6-naphthalene disulfonic acid, and analyze by liquid chromatography (area return One method, the same below) product content 90.17%, percent weight 95.6 kilograms.

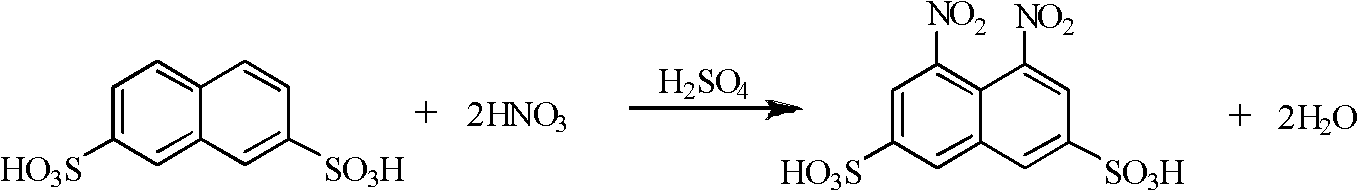

[0047] The second step: nitrification

[0048] Concentrate the filtrate of the above-mentioned sulfonation reaction step under reduced pressure at a vacuum degree of -0.09MPa until the concentration of sulfuric acid is 93%, add 348 kg of concentrated sulfuric acid, then heat up to 35°C, slowly add 85 kg of 98% nitric acid d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com