Method for improving acid production quality and acetic acid proportion in anaerobic fermentation of residue active sludge

A technology of sludge anaerobic fermentation and residual activity, which is applied in the field of sludge treatment and resource utilization, can solve the problems of not paying attention to acid components, reducing the quality of fermentation broth, and being difficult to remove, so as to reduce costs and improve the quality of acid production , The effect of increasing the amount of acetic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

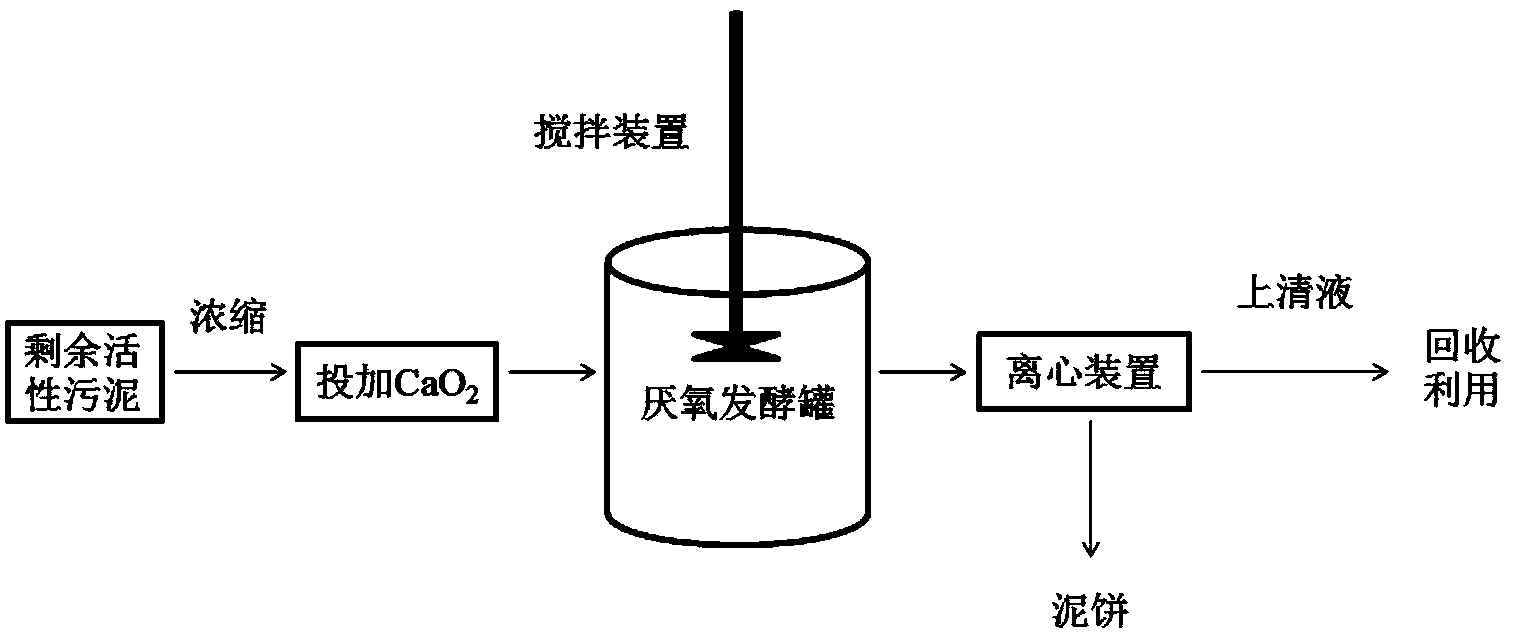

Method used

Image

Examples

Embodiment 1

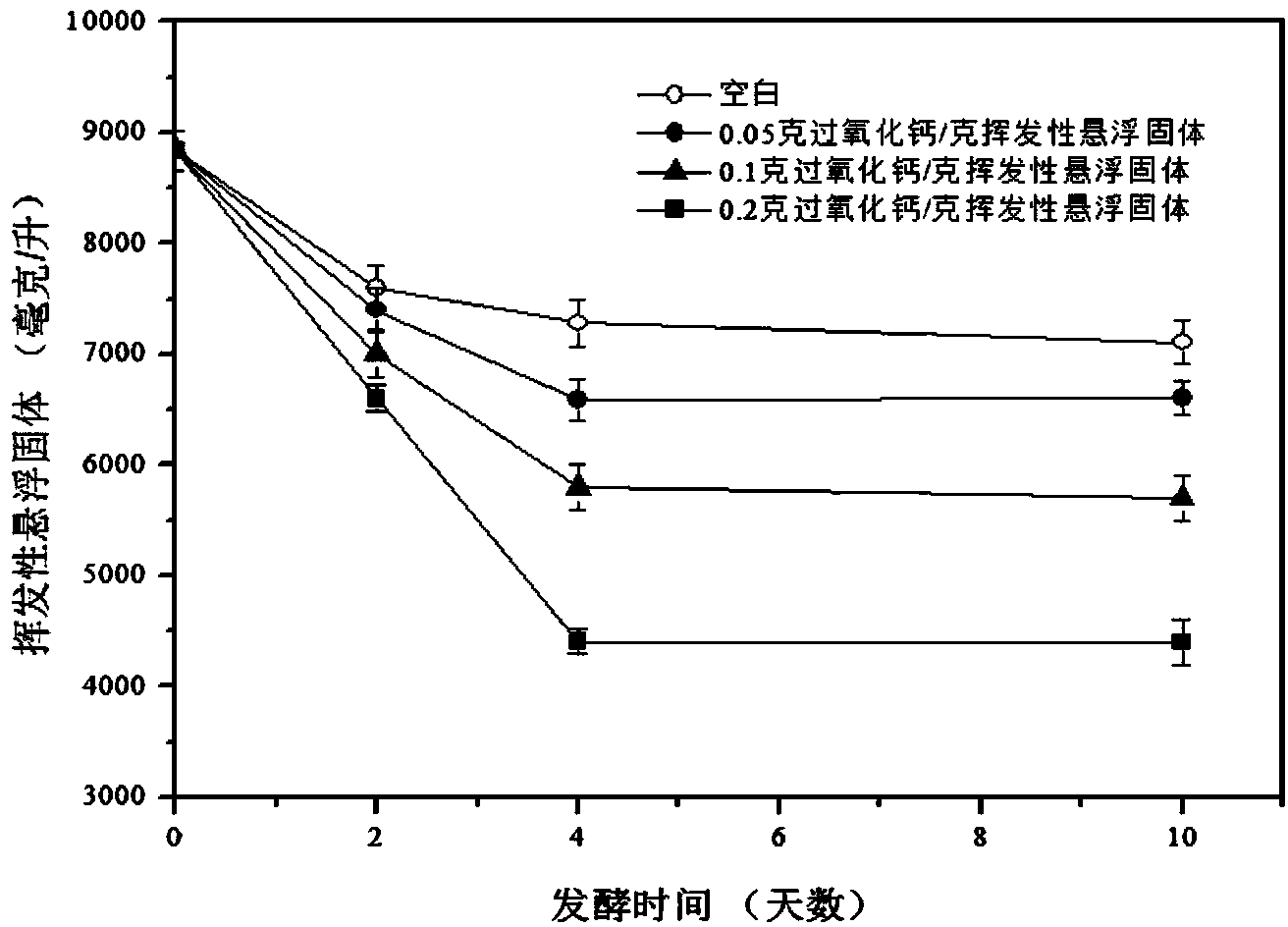

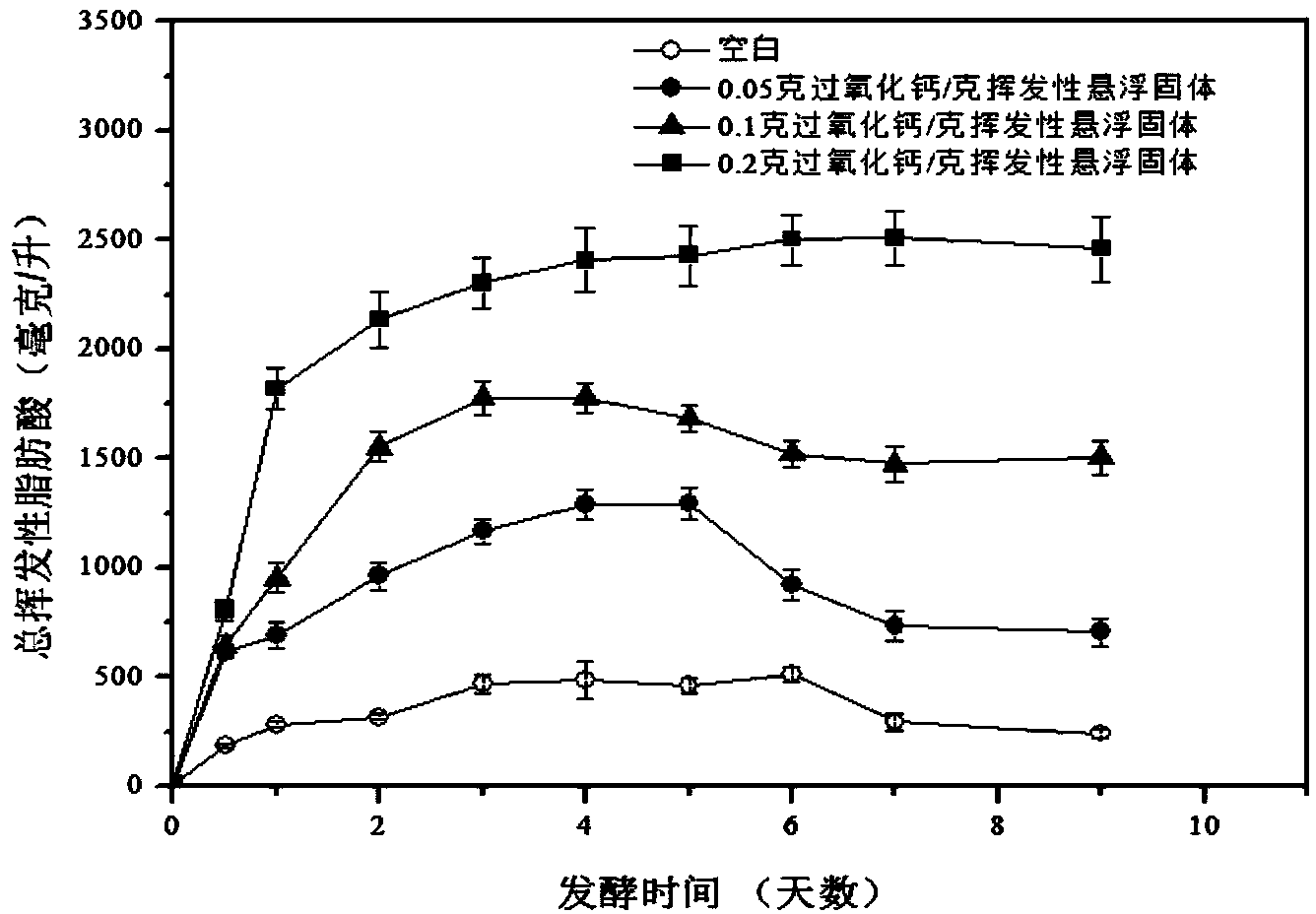

[0027] First concentrate the remaining activated sludge discharged from the sewage treatment plant to VSS=8.8g / L, (TSS is 13g / L, pH is 6.89), add commercially available analytically pure calcium peroxide, and the dosage of calcium peroxide is Add 0.05g of calcium peroxide to the volatile suspended solids, then seal and place in an anaerobic fermentation tank with a temperature of 35°C and a stirring speed of 150rpm for anaerobic fermentation, and the fermentation days are 5 days. Calcium peroxide was not added to the blank group, and other operating conditions were the same. After testing, the dissolution rate of the sludge in the calcium peroxide group was higher than that in the blank group, and the concentration of volatile suspended solids in the calcium peroxide group decreased by 16.3% and 25.5% in the 2nd and 4th days of anaerobic fermentation, respectively. %, while the concentration of volatile suspended solids in the blank group decreased by 14.0% and 18.3% on the 2n...

Embodiment 2

[0029] The remaining activated sludge discharged from the sewage treatment plant is concentrated to VSS=9.8g / L, (TSS is 14.48g / L, pH is 6.89), and commercially available analytical pure calcium peroxide is added, and the dosage of calcium peroxide is Add 0.1g of calcium peroxide to the volatile suspended solids, then seal and place in an anaerobic fermentation tank with a temperature of 35°C and a stirring speed of 150rpm for anaerobic fermentation, and the fermentation days are 5 days. Calcium peroxide was not added to the blank group, and other operating conditions were the same. After testing, the dissolution rate of the sludge in the calcium peroxide group was higher than that in the blank group, and the concentration of volatile suspended solids in the calcium peroxide group decreased by 20.8% and 34.4% in the 2nd and 4th days of anaerobic fermentation, respectively. And the blank group is respectively 14.0% and 18.3%; Adding calcium peroxide group gained volatile acid to...

Embodiment 3

[0031] First concentrate the remaining activated sludge discharged from the sewage treatment plant to VSS=8.8g / L, (TSS is 13g / L, pH is 6.89), add commercially available analytically pure calcium peroxide, and the dosage of calcium peroxide is Add 0.2g of calcium peroxide to the volatile suspended solids, then seal and place in an anaerobic fermentation tank with a temperature of 35°C and a stirring speed of 150rpm for anaerobic fermentation, and the fermentation days are 6 days. Calcium peroxide was not added to the blank group, and other operating conditions were the same. After testing, the dissolution rate of the sludge in the calcium peroxide group was higher than that in the blank group, and the concentration of volatile suspended solids in the calcium peroxide group decreased by 25.4% and 50.2% in the 2nd and 4th days of anaerobic fermentation, respectively. And the blank group is respectively 14.0% and 18.3%; Adding calcium peroxide group gained volatile acid total conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com