Method for treating high-ammonia-nitrogen industrial wastewater of denitration catalyst

A denitration catalyst and a technology for producing wastewater, which are applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. The problem of poor biochemical properties of wastewater can reduce impact, save investment, and improve biochemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

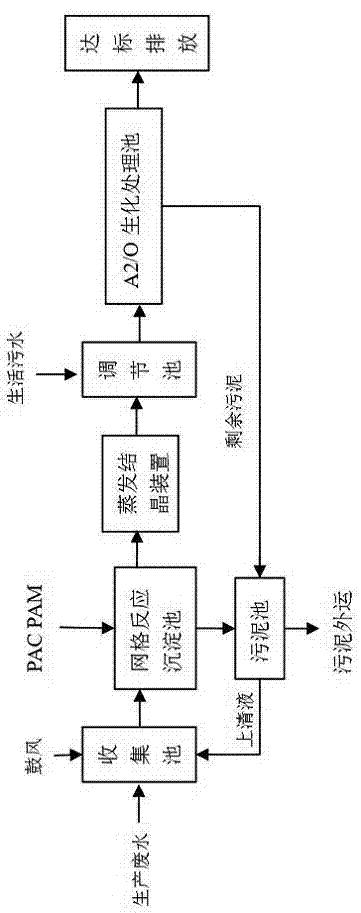

[0034] Embodiment 1: a kind of method of processing waste water produced by high ammonia nitrogen denitrification catalyst of this example, such as figure 1 , the steps are:

[0035] a. After ammonia washing tower, mold cleaning and ground washing wastewater are mixed in the wastewater collection tank and reach a certain level, use air to aerate the wastewater to adjust the mixing evenly, and pre-oxidize some substances;

[0036] b. After the adjusted wastewater is lifted by the pump, polyaluminum chloride (PAC) and polyacrylamide (PAM) are sequentially added into the grid flocculation reaction sedimentation tank. The dosage of PAC is 100mg / L, and the dosage of PAM is 3mg / L;

[0037] c. The flocculation reaction time of the sedimentation tank is 10 minutes. After rectification, the wastewater enters the sedimentation area for sedimentation. The horizontal flow rate is 8mm / s, and the water is discharged in the form of a triangular weir;

[0038] d. The effluent from the sedi...

Embodiment 2

[0042] Embodiment 2: a kind of method of processing waste water produced by high ammonia nitrogen denitrification catalyst of this example, such as figure 1 , the steps are:

[0043] a. After ammonia washing tower, mold cleaning and ground washing wastewater are mixed in the wastewater collection tank and reach a certain level, use air to aerate the wastewater to adjust the mixing evenly, and pre-oxidize some substances;

[0044] b. After the adjusted wastewater is lifted by the pump, polyaluminum chloride (PAC) and polyacrylamide (PAM) are sequentially added into the grid flocculation reaction sedimentation tank. The dosage of PAC is 110mg / L, and the dosage of PAM is 4mg / L;

[0045] c. The flocculation reaction time of the sedimentation tank is 13 minutes. After rectification, the wastewater enters the sedimentation area for sedimentation. The horizontal flow rate is 89mm / s, and the water is discharged in the form of a triangular weir;

[0046] d. The effluent from the sed...

Embodiment 3

[0050] Embodiment 3: a kind of method of processing waste water produced by high ammonia nitrogen denitrification catalyst of this example, such as figure 1 , the steps are:

[0051]a. After ammonia washing tower, mold cleaning and ground washing wastewater are mixed in the wastewater collection tank and reach a certain level, use air to aerate the wastewater to adjust the mixing evenly, and pre-oxidize some substances;

[0052] b. After the adjusted wastewater is lifted by the pump, polyaluminum chloride (PAC) and polyacrylamide (PAM) are sequentially added into the grid flocculation reaction sedimentation tank. The dosage of PAC is 120mg / L, and the dosage of PAM is 5mg / L;

[0053] c. The flocculation reaction time of the sedimentation tank is 15 minutes. The wastewater enters the sedimentation area after rectification for sedimentation. The horizontal flow rate is 10mm / s, and the water is discharged in the form of a triangular weir;

[0054] d. The effluent from the sedim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com