Integrated white wine production waste water treatment device

A technology for the production of waste water and treatment equipment, which is applied in the fields of food industry waste water treatment, flotation water/sewage treatment, neutralization water/sewage treatment, etc. It can solve cleaning difficulties, high treatment costs, limited removal of phosphate and nitrogen, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

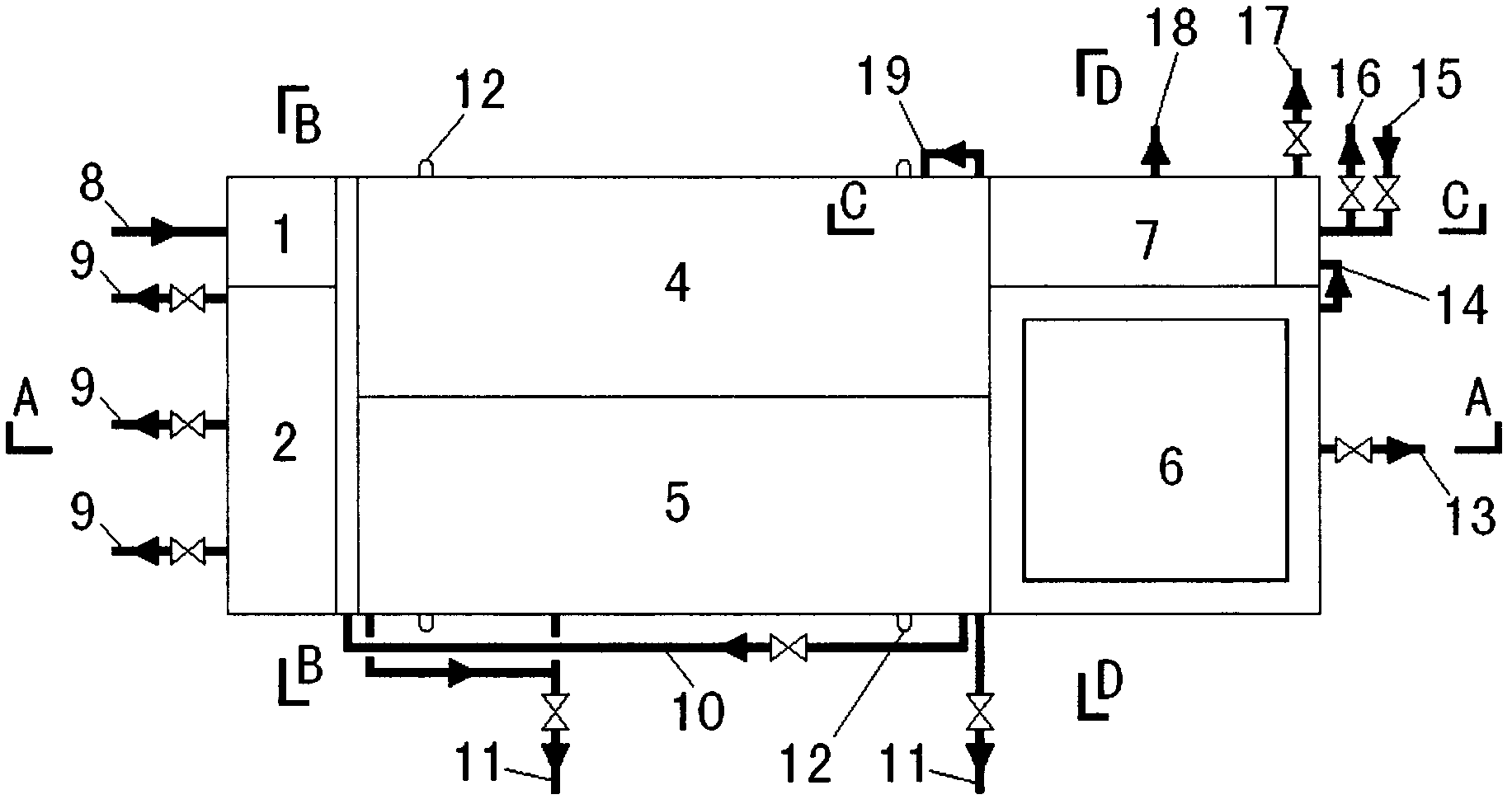

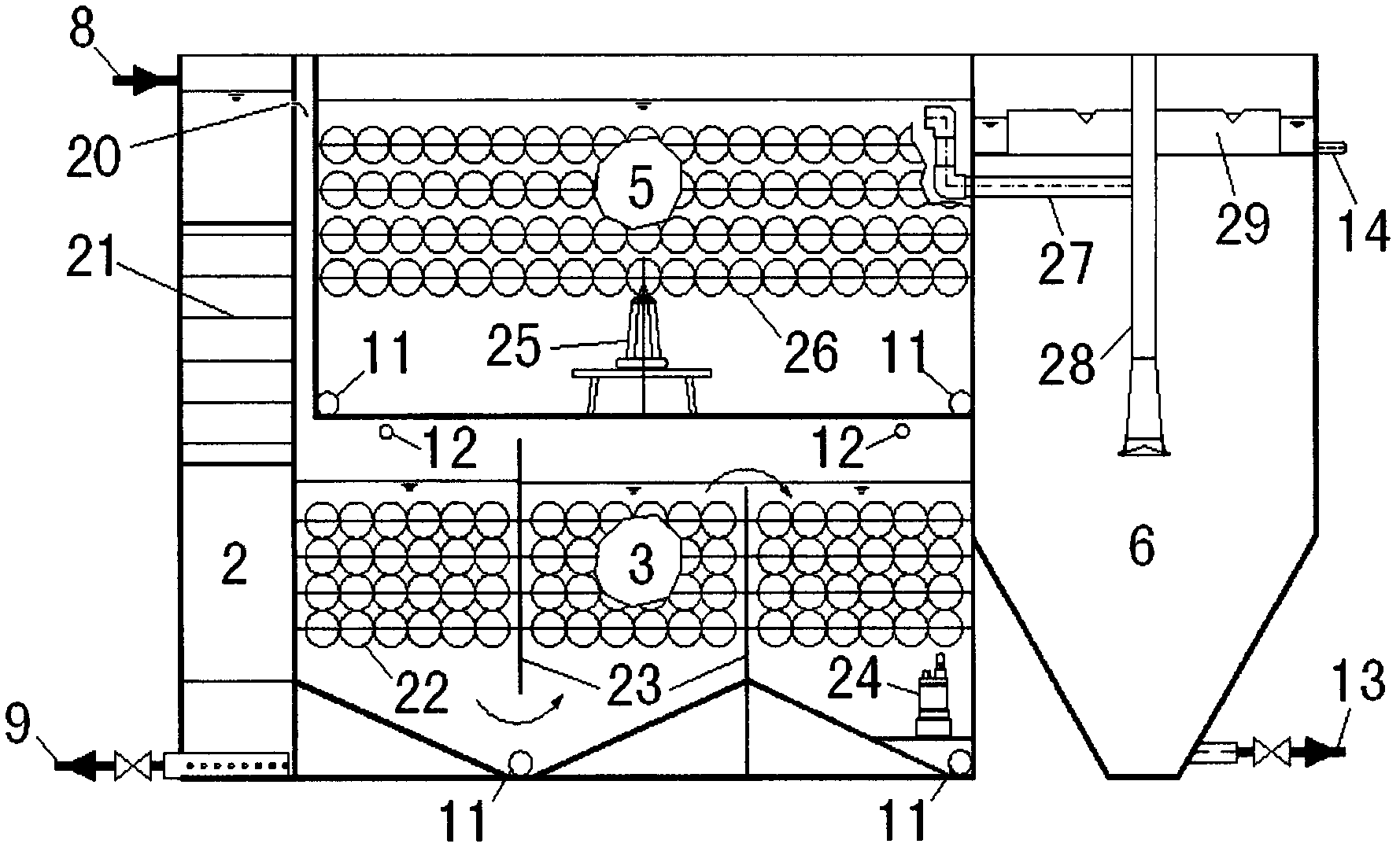

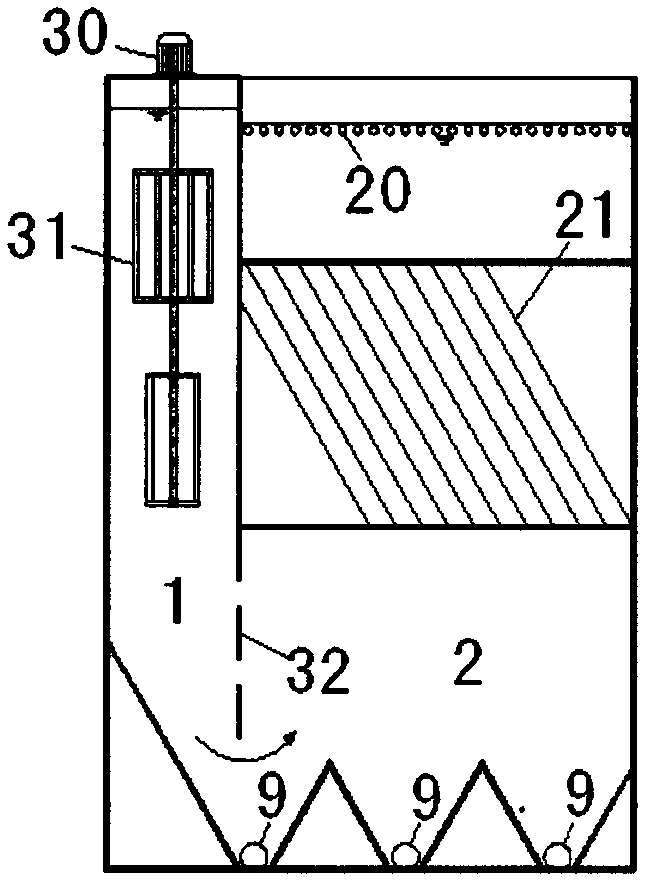

[0048] Such as figure 1 , figure 2 and image 3 As shown, the flocculation stirring zone 1 is adjacent to the inclined plate sedimentation zone 2, and they are both located on the water inlet side of the integrated treatment device, and the two are separated by a perforated flow partition 32 . A flocculation stirring motor 30 is installed on the top of the flocculation stirring zone 1, and the flocculation stirring paddle 31 is installed on the transmission shaft of the flocculation stirring motor 30, and the flocculation stirring paddle 31 stirs the wastewater driven by the flocculation stirring motor 30, so that the small particles in the wastewater Suspended solids condense into large particles of alum and settle down in inclined plate sedimentation zone 2. The flocculation stirring paddles 31 have two different specifications, so that the wastewater is subject to different stirring intensities in the process of flowing from top to bottom, so as to meet the requirements fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com