Method for processing degradation-resistant organic wastewater and multi-element catalyst adopted by method

A technology for organic wastewater and organic wastewater treatment, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve immature large-scale engineering applications and power consumption Large and other problems, to achieve the effect of less catalyst consumption and loss, low operating costs, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Treatment of refractory wastewater in a chemical industry park, wastewater COD Cr The average is 537mg / L, the pH is about 7.5, and the oxidant is 30% mass concentration hydrogen peroxide. The experimental steps are as follows: the dosage of hydrogen peroxide is 500 mg / l, and after the hydrogen peroxide and waste water are fully mixed for 0.5h, enter the Fenton-like hydrogen peroxide filled with the present invention. Multi-catalyst reaction column, the reaction column is made of De160 UPVC pipe closed at both ends, 1.0m high, filled with 5kg of the above-mentioned catalyst, the water flow rate is 4L / h, continuous operation, the residence time of wastewater in the reaction column is 1.5 h, effluent COD after reaction Cr The concentration is 376mg / L, COD Cr The average removal rate was 30.0%. The influent flow rate is halved or the residence time of wastewater in the reaction column is doubled, and the COD Cr The removal rate increased by about 5.2%; increas...

Embodiment 2

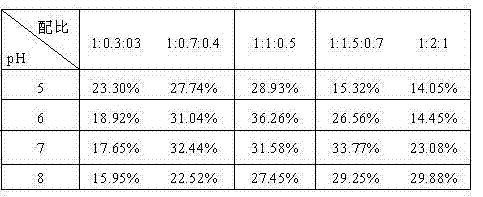

[0044] Example 2: Composite catalysts of different proportions are used to treat refractory wastewater. The water sample to be treated is the same as in Example 1. Hydrochloric acid and sodium hydroxide are used to adjust the pH value of the wastewater. The oxidant is 30% mass concentration hydrogen peroxide, and the mass ratio of activated carbon to iron alloy is 1. : 2, experimental procedure is the same as embodiment 1, specifically as follows: hydrogen peroxide dosage is 500mg / l, after hydrogen peroxide and waste water fully mix 0.5h, enter respectively the reaction column that is filled with the multiple catalyst of different proportioning, reaction column is made of De160 The two ends of the UPVC pipe are closed, the height is 1.0m, and the above-mentioned catalyst is filled with 5kg, the water flow rate is 4L / h, and the continuous operation, the residence time of the wastewater in the reaction column is 1.5h. Partial Composite Catalyst Fe, Cu, Mn Compound Ratio and Waste...

Embodiment 3

[0048] Embodiment 3: adopt the composite catalyst of different Fe-containing compounds to treat wastewater, the wastewater to be treated is the same as in Example 1, adopt ferroalloy, iron filings, and iron oxide powder according to the present invention respectively, and the mass ratio of activated carbon to Fe-containing compounds is 1:2, The mass ratio of Fe-containing compound, Cu compound and Mn-containing compound is 1:1:0.5. The experimental procedure is the same as in Example 1. The specific steps are as follows: the dosage of hydrogen peroxide is 500mg / l, and after the hydrogen peroxide and wastewater are fully mixed for 0.5h, enter The reaction column is filled with a multi-component catalyst that does not contain Fe compounds. The reaction column is made of De160 UPVC pipe with both ends closed. It is 1.0m high and filled with 5kg of the above-mentioned catalyst. The residence time in the reaction column is 1.5h, and the system runs continuously for 1 month. Ferroal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com