Method for preparing unbleached pulp and producing high-strength corrugated paper from cotton stalk

A production method and technology of corrugated paper, applied in pulp beating method, pulp beating/refining method, papermaking, etc., can solve problems such as pulping pollution, and achieve the effects of reducing pollution, reducing costs, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

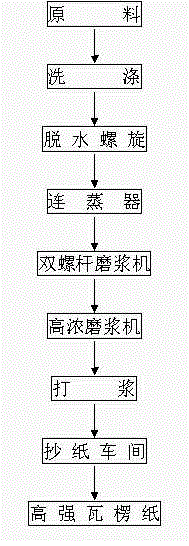

Image

Examples

Embodiment 1

[0020] Pulping section:

[0021] (1) Cotton stalks are cut into sections of about 30mm by a pulverizer.

[0022] (2) The qualified cotton stalk raw material is conveyed to the washing machine by metering screw, washed, dehydrated by screw extrusion, and the light and heavy impurities in the raw material are removed.

[0023] (3) The dehydrated raw materials are conveyed to the screw feeder by metering screw, and sent to the continuous steamer, and then add 1kg of biocatalyst, 1kg of trisodium phosphate and 1kg of polyoxyethylene ether per ton of absolute dry cotton stalk, Then, steam was introduced, and the temperature was raised to 120° C. for continuous cooking for 25 minutes.

[0024] (4) After cooking, the material in the continuous steamer is transported to a twin-screw refiner (SLG-300, Hebei Tianzheng Screening Pulping Equipment Co., Ltd.) for 1 min of rubbing and separating to obtain the natural color paste.

[0025] Papermaking section:

[0026] (1) After adjusting...

Embodiment 2

[0029] The difference from Example 1 is that when cooking in step (2), 5 kg of biocatalyst, 3 kg of trisodium phosphate and 1 kg of polyoxyethylene ether are added per ton of dry cotton stalk, and then water vapor is introduced to raise the temperature. Continue cooking at 120°C for 20 minutes.

Embodiment 3

[0031] The difference from Example 1 is that when cooking in step (2), 2 kg of biocatalyst, 2 kg of trisodium phosphate and 2 kg of polyoxyethylene ether are added per ton of dry cotton stalk, and then water vapor is introduced to raise the temperature. Continue cooking at 115°C for 30min.

[0032] Adopt method of the present invention to compare as follows with traditional ammonium chemical method:

[0033] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com