Manganese charcoal catalytic internal electrolysis filler as well as preparation method and application thereof

An internal electrolysis, manganese carbon technology, applied in chemical instruments and methods, water treatment parameter control, multi-stage water treatment, etc. , High COD removal rate, rapid and thorough reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

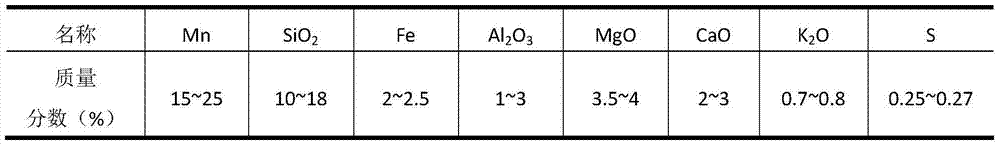

Method used

Image

Examples

Embodiment 1

[0040] Mix 75g of manganese ore waste and 75g of activated carbon, grind them, and pass through a 100-130 mesh sieve. Then add kaolin 40g, coal powder 15g, mix and stir evenly. Slowly shake it after adding a certain amount of water to form spherical particles with a particle size of 1-2 mm. Then put it into a muffle furnace and gradually raise the temperature to 70-80°C at a rate of 3-5°C / min, continue drying for 20 minutes, steam the water out, and finally sinter the above-mentioned manganese-carbon material at 1100°C under the condition of nitrogen filling for 2 hours, and roast After the completion, the packing is taken out and cooled to obtain the manganese-carbon catalytic inner electrolytic packing with a specific surface area of 1.30m 2 / g, the porosity is 66%. 200ml solution with COD concentration of 3000mg / L, adjust the pH to 3, put 200g of manganese carbon electrolytic material into it, after aeration for 2 hours, adjust the pH to 8, remove the supernatant to mea...

Embodiment 2

[0042]Mix 75g of manganese ore waste and 75g of activated carbon, grind them, and pass through a 100-130 mesh sieve. Then add kaolin 40g, coal powder 15g, mix and stir evenly. Slowly shake it after adding a certain amount of water to form spherical particles with a particle size of 3-5 mm. Then put it into a muffle furnace and gradually raise the temperature to 70-80°C at a rate of 3-5°C / min, continue drying for 20 minutes, steam the water out, and finally sinter the above-mentioned manganese-carbon material at 1100°C under the condition of nitrogen filling for 2 hours, and roast After the completion, the packing is taken out and cooled to obtain the manganese-carbon catalytic inner electrolytic packing with a specific surface area of 1.13m 2 / g, the porosity is 65%. 200ml solution with COD concentration of 3000mg / L, adjust the pH to 3, put 200g of manganese carbon electrolytic material into it, after aeration for 2 hours, adjust the pH to 8, remove the supernatant to meas...

Embodiment 3

[0044] Mix 75g of manganese ore waste and 60g of activated carbon, grind them, and pass through a 100-130 mesh sieve. Then add kaolin 40g, coal powder 15g, mix and stir evenly. Slowly shake it after adding a certain amount of water to form spherical particles with a particle size of 1-2mm. Then put it into a muffle furnace and gradually raise the temperature to 70-80°C at a rate of 3-5°C / min, continue drying for 20 minutes, steam the water out, and finally sinter the above-mentioned manganese-carbon material at 1100°C under the condition of nitrogen filling for 2 hours, and roast After the completion, the packing is taken out and cooled to obtain the manganese-carbon catalytic inner electrolytic packing with a specific surface area of 1.28m 2 / g, the porosity is 65%. 200ml solution with COD concentration of 3000mg / L, adjust the pH to 3, put 200g of manganese carbon electrolytic material into it, after aeration for 2 hours, adjust the pH to 8, remove the supernatant to meas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com