Wastewater treatment filling material and preparation method thereof

A waste water treatment, waste water technology, applied in the direction of energy waste water treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of waste materials that are easily affected by the environment, low treatment efficiency, easy caking, etc., to achieve Improved settling performance, large processing capacity, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

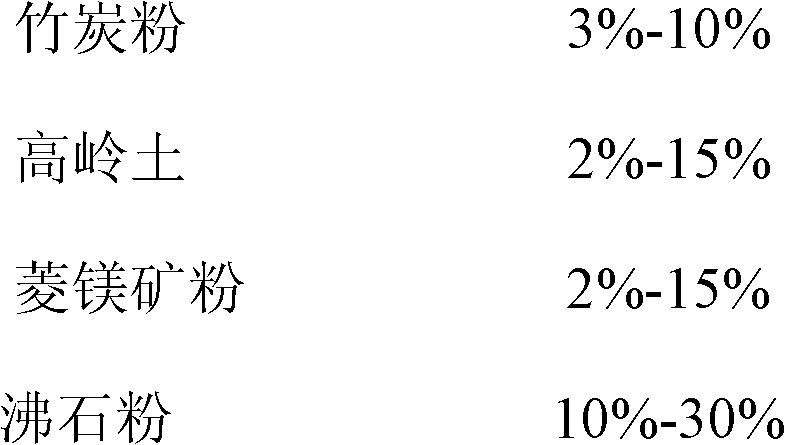

[0029] Proportioning (percentage by weight):

[0030]

[0031]

[0032] Preparation method: First, the raw materials of each component are pulverized and ball-milled to 10-micron powder, then uniformly mixed according to the weight percentage of each component, and finally made into granules. After granulation, it is sintered at a temperature of 600° C. to form spherical particles with a diameter of 2 mm.

[0033] Usage method: Take 10 grams of spherical particles and add 30 ml of waste water from acrylic fiber factory, and stir for 30 minutes. The main component of this wastewater that needs to be degraded is acrylonitrile compound. The wastewater before and after treatment is measured with a COD measuring instrument. The results show that the COD value of the wastewater from the acrylic fiber factory is reduced from 1280 to 384 after being treated with the wastewater treatment filler filler of the present invention. The degradation rate was 70%.

Embodiment 2

[0035] Proportioning (percentage by weight):

[0036]

[0037] The preparation method: the raw materials of each component are pulverized and ball-milled to 80 nanometer powder, and then uniformly mixed according to the weight percentage of each component, and finally made into granules. After granulation, it was sintered at a temperature of 800° C. to form spherical particles with a diameter of 3 mm.

[0038] Usage method: Take 10 grams of spherical particles and add it to 30 ml of erythromycin pharmaceutical wastewater, and stir for 30 minutes. The main component that needs to be degraded in the erythromycin pharmaceutical wastewater is a heterocyclic compound. The COD measuring instrument is used to measure the wastewater before and after the treatment. The results show that the COD value of the erythromycin pharmaceutical wastewater after being treated with the waste water treatment filler of the present invention is by 3200 is reduced to 1024, and the degradation rate...

Embodiment 3

[0040] Proportioning (percentage by weight):

[0041]

[0042] The preparation method: the raw materials of each component are pulverized and ball-milled to 50-micron powder, and then uniformly mixed according to the weight percentage of each component, and finally made into granules. After granulation, it is cold-pressed into a cylindrical shape with a diameter of 2 cm and a height of 5 cm.

[0043] How to use: Take 1 kg of waste water treatment filler and put it into the pool, add 10 kg of coking waste water, and aerate for 30 minutes. The main components that need to be degraded in the coking wastewater are organic nitrogen compounds and benzene ring compounds. The COD measuring instrument is used to measure the wastewater before and after the treatment. The results show that the COD value of the coking wastewater after being treated with the waste water treatment filler filler of the present invention is changed from 4200 to 4200. Reduced to 840, the degradation rate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com