High-carbonaceous metallized pellet for treating waste water and preparation method

A technology for metallized pellets and wastewater treatment, which is applied in electrochemical water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the unstable treatment effect of organic wastewater, reduce the degradation rate of pollutants, and reduce the electron transfer rate and other problems, to achieve the effects of easy fluidization, accelerated mass transfer rate, and reduced concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

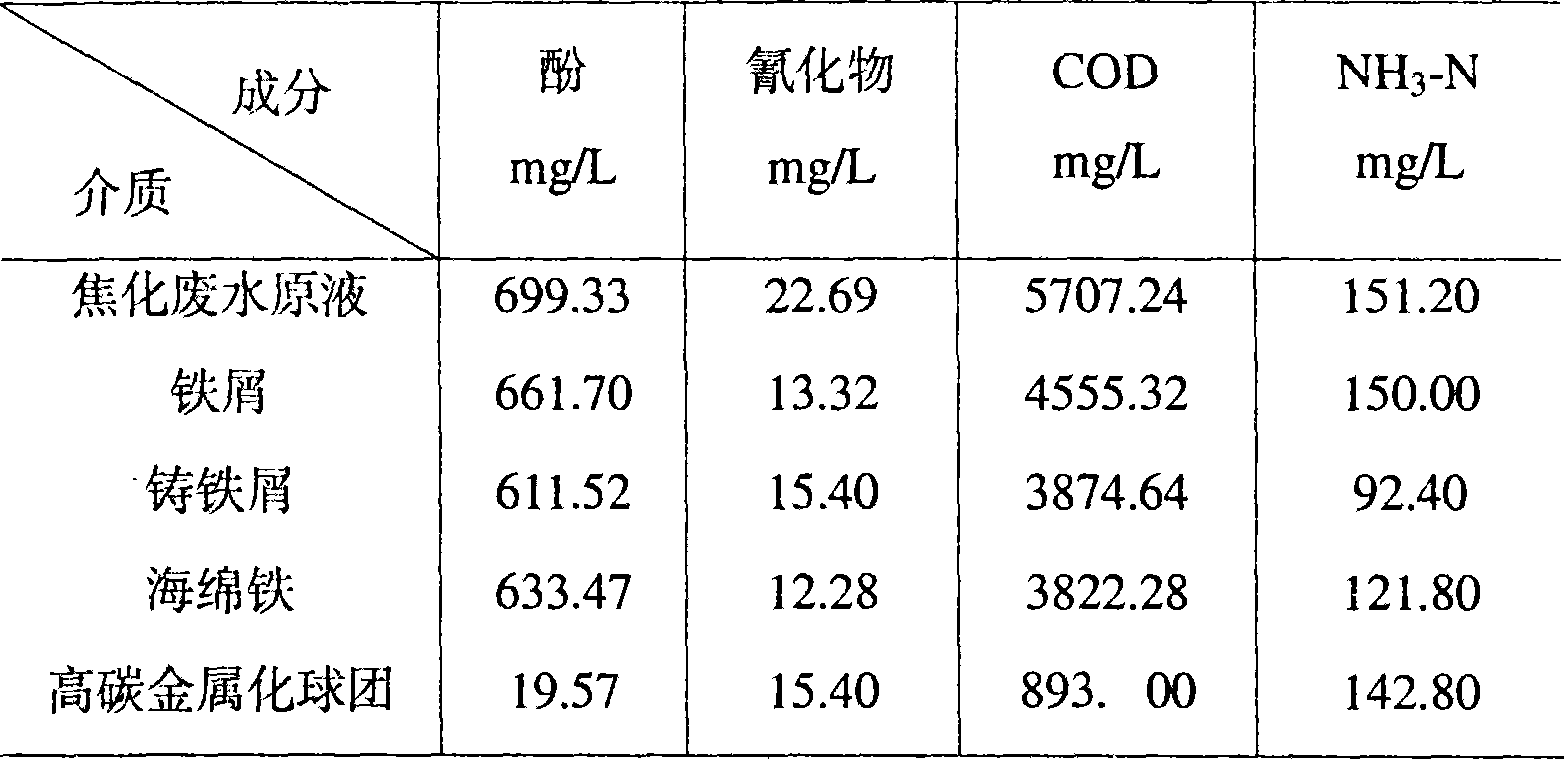

Image

Examples

Embodiment 1

[0035] Weigh the raw materials according to weight percentage: 60% of iron concentrate powder, 30% of coal powder, and 10% of bentonite; each raw material is mixed evenly and crushed into a powder with a particle size of 100 mesh; Balls, the diameter of the balls is controlled at 2-10 mm; the pellets are put into a drying oven to dry; the dried pellets are reduced at 1050° C. for 2 hours, and cooled naturally.

Embodiment 2

[0037] Raw materials are weighed according to weight percentage: 40% of iron concentrate powder and rich ore powder, 50% of coal powder and sawdust, 10% of starch and clay; each raw material is mixed evenly and crushed into a powder with a particle size of 100 mesh; the pulverized The raw materials are pelletized by adding water in a disc pelletizer, and the diameter of the pellets is controlled at 2-10mm; the pellets are naturally dried; the dried pellets are reduced at 1200°C for 1.5 hours, and then cooled naturally.

Embodiment 3

[0039] Raw materials are weighed according to weight percentage: 70% of rolled iron scale, 20% of anthracite and chaff, 10% of bentonite and starch; the raw materials are mixed evenly and pulverized into powder with a particle size of 100 mesh; Add water to the ball machine to form pellets, and the diameter of the balls is controlled at 2-10mm; the pellets are placed in a drying oven to dry; the dried pellets are reduced at 800°C for 3 hours, and then cooled naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com