UV-curable colored paint composition

A technology of colored coatings and compositions, applied in the field of UV curable colored coating compositions, which can solve the problems of energy consumption, time-consuming, semi-drying, etc., and achieve the effects of high production efficiency, low cost, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

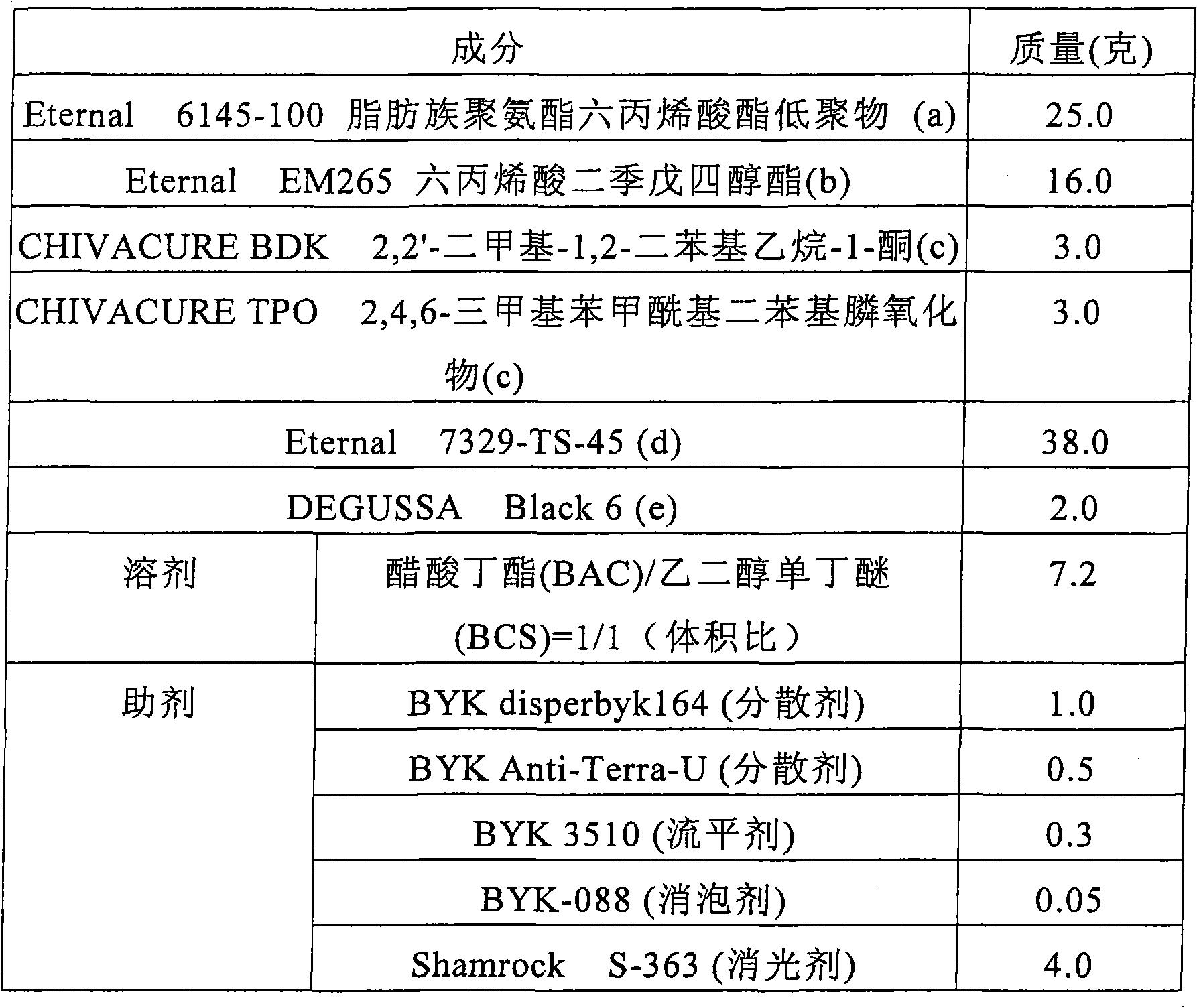

Embodiment 1

[0078] Table 1

[0079]

[0080] Add the diluent (butyl acetate / toluene / ethylene glycol monobutyl ether = 2 / 2 / 1 (volume ratio)) to the Iwata cup of the composition obtained above for about 10 seconds, and spray it on the plastic substrate with an air spray gun. Then pre-bake in an oven at 60°C for 5 to 10 minutes, and then pass through a medium-pressure mercury lamp (800mJ / cm 2 ) for exposure. Then, the substrate with the coating film after exposure is subjected to a physical property test.

[0081] The physical test results are as follows:

[0082] The coating film forms a coating film of 12-20μm

[0083] Adhesion between coating film and substrate: 100 / 100

[0084] Coating film hardness: ≥H

[0085] Coating film gloss: 65

[0086] Coating film heat resistance: pass (appearance without cracks, peeling off)

[0087] Appearance: flat, with a black semi-matte effect.

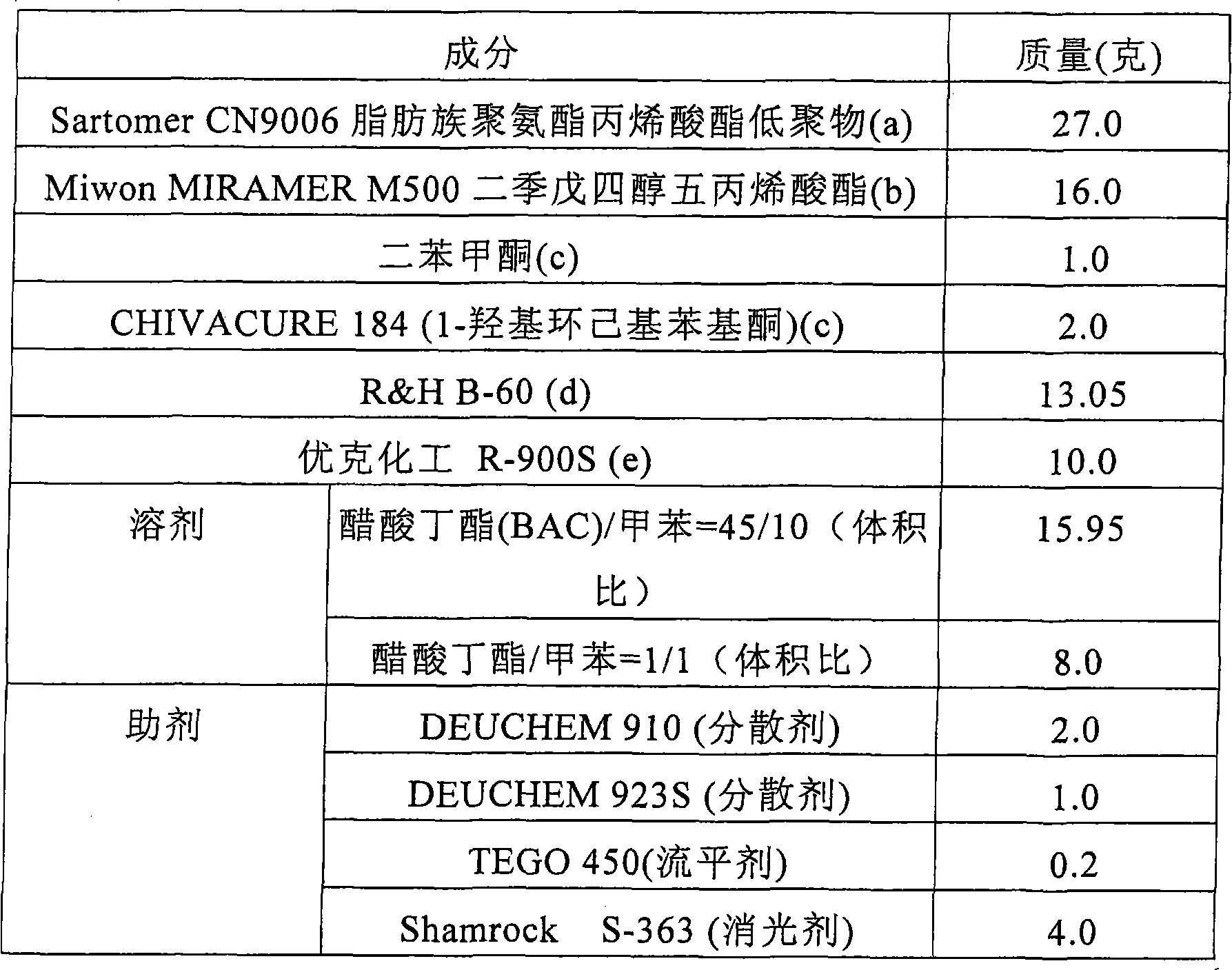

Embodiment 2

[0089] Table 2

[0090]

[0091] Add the diluent (butyl acetate / toluene / ethylene glycol monobutyl ether = 2 / 2 / 1 (volume ratio)) to the Iwata cup of the composition obtained above for about 10 seconds, and spray it on the plastic substrate with an air spray gun. Then pre-bake in an oven at 60°C for 5 to 10 minutes, and then pass through a medium-pressure mercury lamp (800mJ / cm 2 ) for exposure. Then, the substrate with the coating film after exposure is subjected to a physical property test.

[0092] The results of the physical property test are as follows:

[0093] The coating film forms a coating film of 10-15 μm

[0094] Adhesion between coating film and substrate: 100 / 100

[0095] Coating film hardness: ≥H

[0096] Coating gloss: 85

[0097] Coating film heat resistance: pass (appearance without cracks, peeling off)

[0098] Appearance: Flat with a pearly semi-gloss effect.

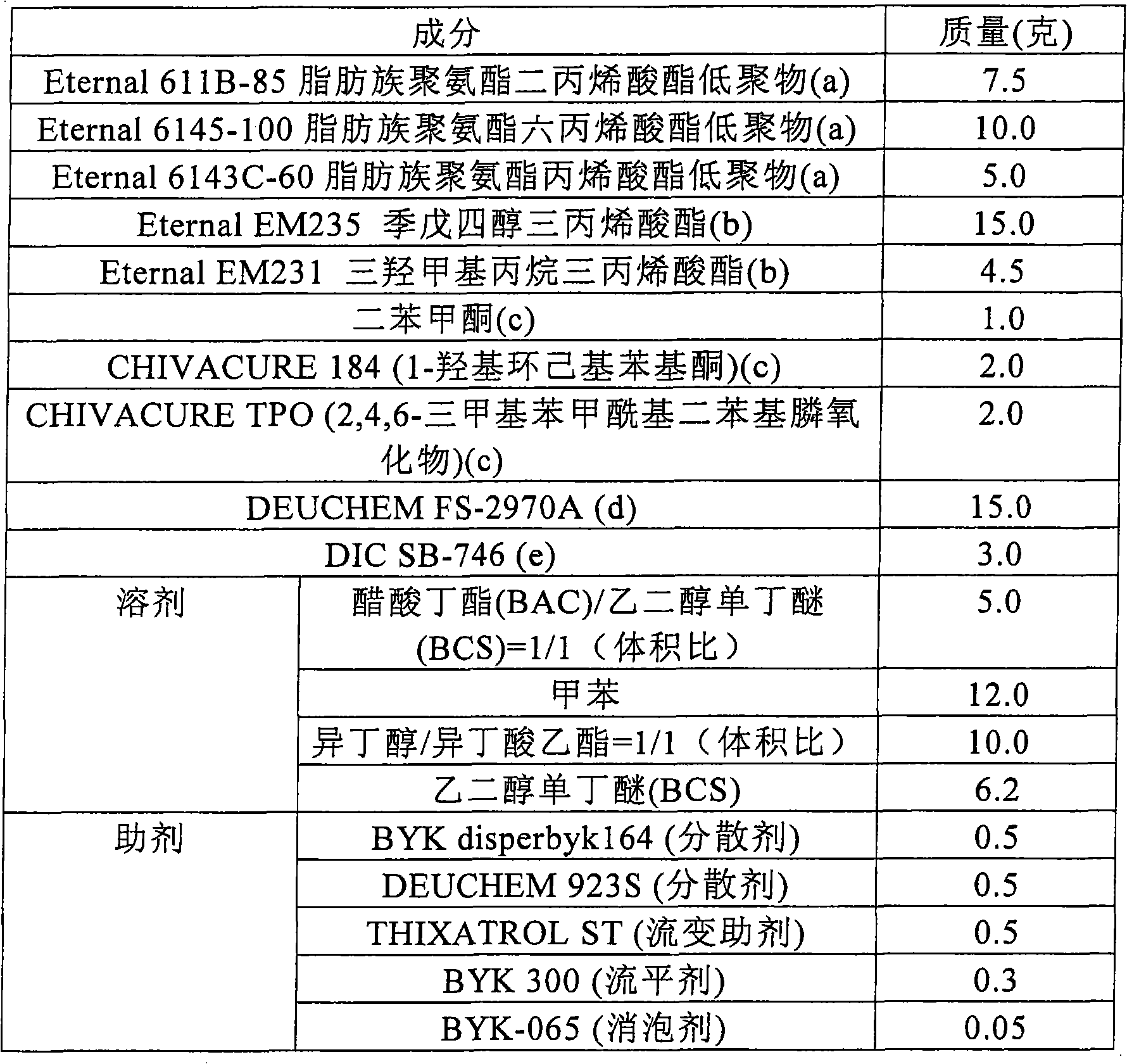

Embodiment 3

[0100] table 3

[0101]

[0102] Add the diluent (butyl acetate / toluene / ethylene glycol monobutyl ether = 2 / 2 / 1 (volume ratio)) to the Iwata cup of the composition obtained above for about 10 seconds, and spray it on the plastic substrate with an air spray gun. Then pre-bake in an oven at 60°C for 5 to 10 minutes, and then pass through a medium-pressure mercury lamp (800mJ / cm 2 ) for exposure. Then, the substrate with the coating film after exposure is subjected to a physical property test.

[0103] The results of the physical property test are as follows:

[0104] The coating film forms a coating film of 20-25μm

[0105] Adhesion between coating film and substrate: 100 / 100

[0106] Coating film hardness: ≥HB

[0107] Coating film gloss: 90

[0108] Coating film heat resistance: pass (appearance without cracks, peeling off)

[0109] Appearance: flat, with blue full light effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com