Long distance concentrated phase conveying system and method with auxiliary blowing apparatus

A conveying system and long-distance technology, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of poor pipeline wear, high alumina damage rate, pipeline wear, etc., and achieve the convenience of crossing roads or buildings Objects, small footprint, and the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

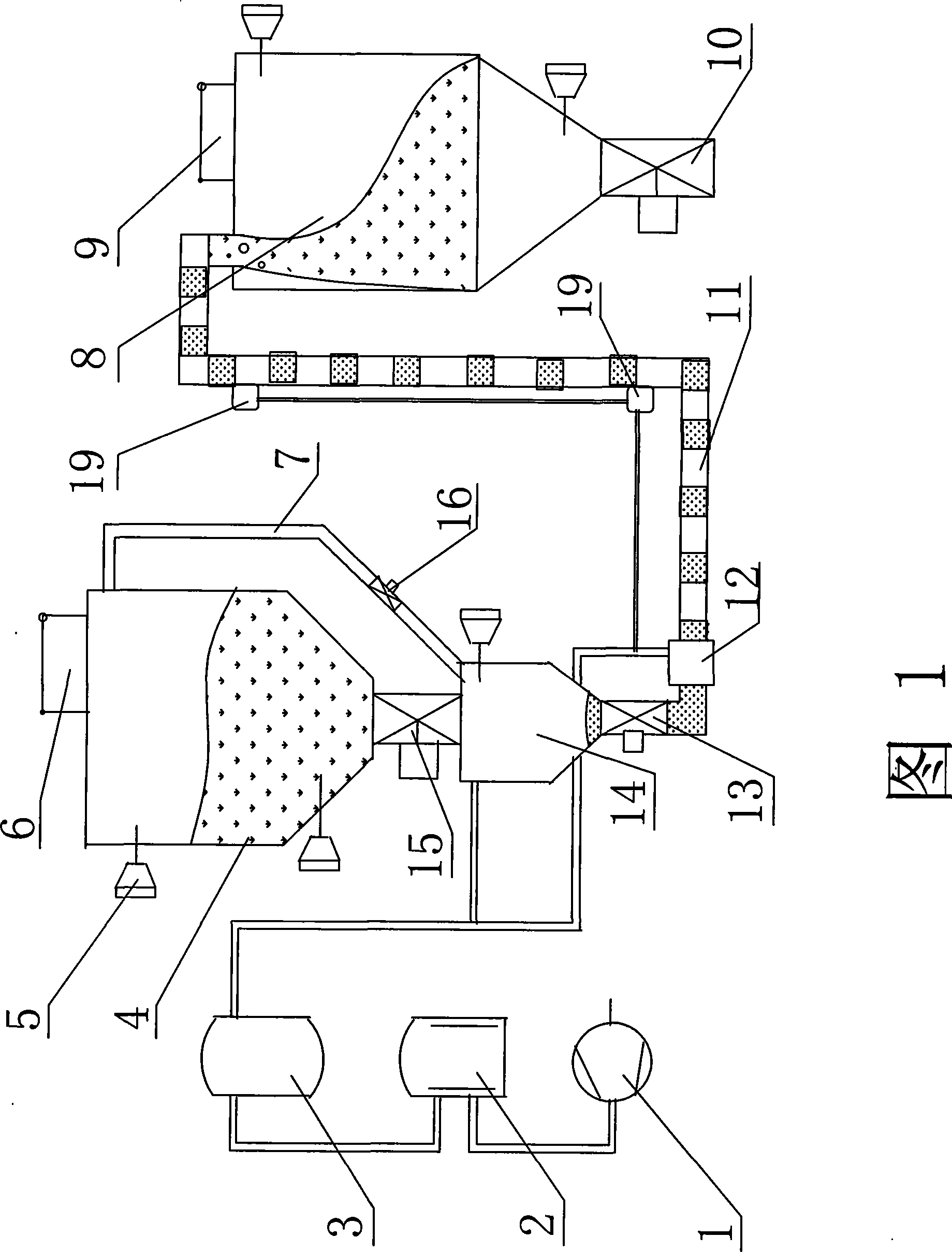

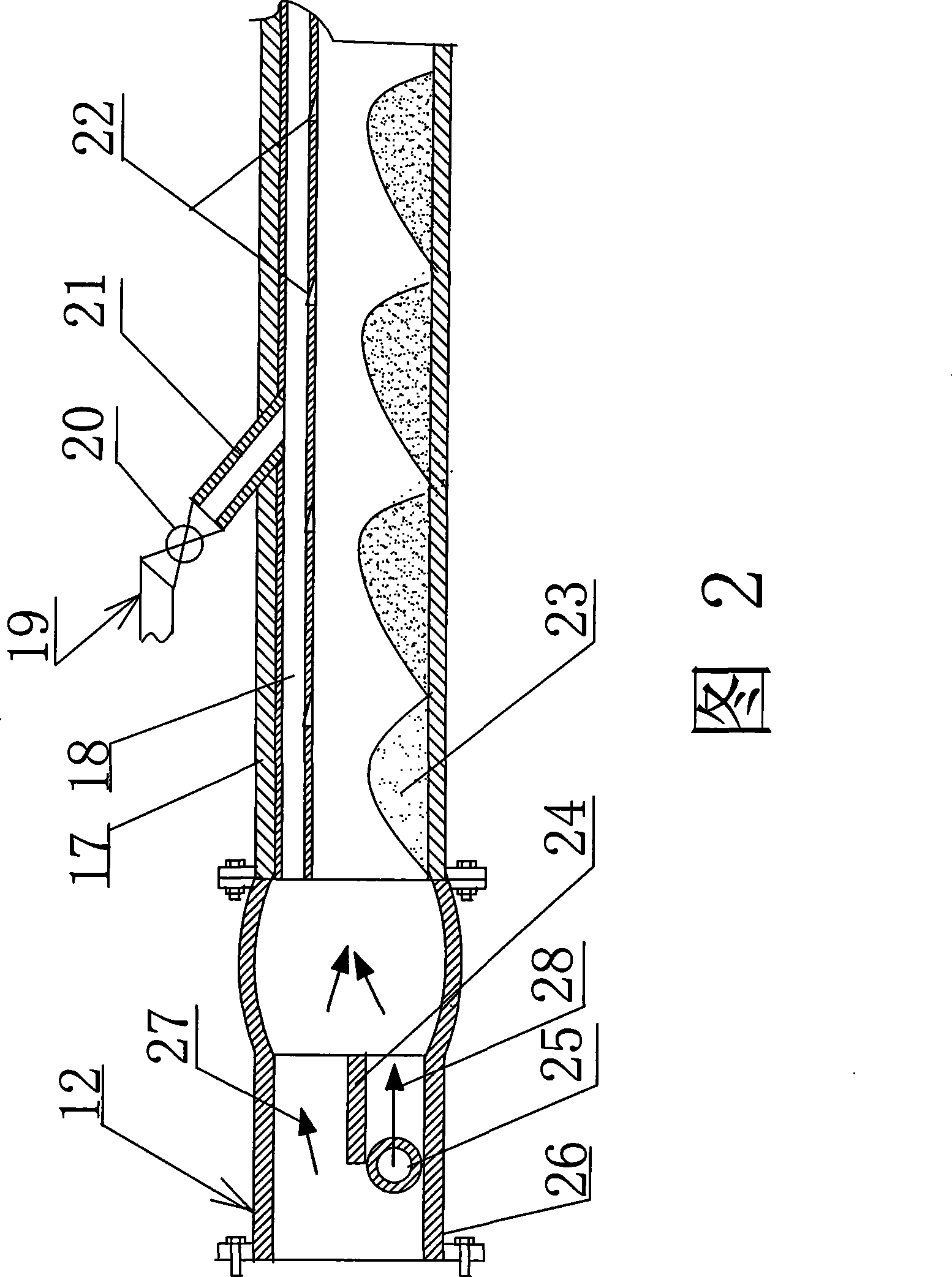

[0024] This example is a long-distance dense-phase conveying system with blowing aid for alumina transportation, including air control device, storage bin 4, sending tank 14, fluidized conveyor 12, online branch silo 8 and dense-phase conveying pipeline 11. The dense phase conveying pipeline 11 is composed of a conveying outer pipe 17, an inner lining pipe 18 and a blowing aid device 19. One side of the inner lining pipe 18 is provided with an air blowing port 22 in sections, and the inner lining pipe 18 is inserted into the conveying outer pipe 17. The liner pipe 18 is fixedly connected to the inner upper wall of the delivery outer pipe 17 with the air blowing port 22 opposite the other side, and the auxiliary blowing device 19 is composed of an inclined nozzle 21 and a control valve 20. The sections are welded on the delivery outer pipe 17 and the inner liner 18, and the inclined nozzle 21 communicates with the inner liner 18. Described fluidization conveyer 12 is made of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com