Preparation method of flake-shaped aragonite calcium carbonate

A technology of calcium carbonate and aragonite, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of difficult control of process conditions, difficult industrialized production, large process energy consumption, etc., and achieve good economic and social benefits, mild operating conditions, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The steps of the preparation method of flaky aragonite calcium carbonate are as follows:

[0022] 1) Coarsely pulverize the shells by dry method, soak in the lotion at room temperature for 4 to 48 hours, wash with a drum to remove the horny layer and prismatic layer, and wash with water to obtain nacreous calcium carbonate;

[0023] 2) Mix nacre calcium carbonate with water at a high speed to obtain a slurry with a mass percentage concentration of 30-80%, add grinding aids equivalent to 0.5-5% of the weight of nacre calcium carbonate, and use a peeling machine with zirconia balls, Alumina balls or ceramic balls are used as grinding media, and wet grinding takes 60 to 180 minutes;

[0024] 3) Pressure filtration, drying and crushing to obtain flaky aragonite calcium carbonate.

[0025] The shells are mussel shells, scallop shells, oyster shells, pearl shells or mussel shells. The washing solution is dilute hydrochloric acid, dilute sulfuric acid, dilute acetic acid, di...

Embodiment 1

[0028] 1) dry coarsely pulverize the purple mussel shell, soak it in 0.1% dilute hydrochloric acid at normal temperature for 4 hours, wash it with a drum to remove the cuticle and prism layer, and wash it to get nacre calcium carbonate;

[0029] 2) Nacre calcium carbonate was mixed with water at a high speed to obtain a slurry with a concentration of 30 wt%, and polyacrylic acid equivalent to 0.5% of the weight of nacre calcium carbonate was added, and the zirconia ball was used as a grinding medium with a peeling machine, and wet grinding was carried out for 60 minute;

[0030] 3) Pressure filtration, drying and crushing to obtain flaky aragonite calcium carbonate.

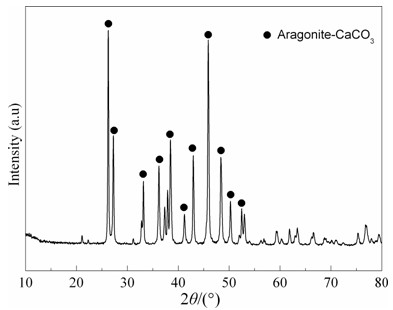

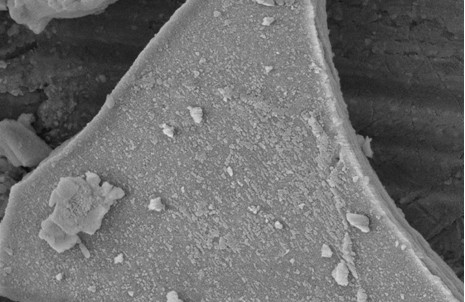

[0031] The sample XRD chart is attached figure 1 , see the attached electron microscope scanning figure 2 .

Embodiment 2

[0033] 1) scallop shells are dry coarsely crushed, soaked in a 3% sodium hypochlorite solution at normal temperature for 48 hours, washed with a drum to remove cuticles and prismatic layers, and washed to obtain nacre calcium carbonate;

[0034] 2) Nacre calcium carbonate was mixed with water at a high speed to obtain a slurry with a concentration of 80 wt%, and sodium silicate equivalent to 5% of the weight of nacre calcium carbonate was added, and the aluminum oxide ball was used as a grinding medium with a peeling machine, and wet grinding was carried out for 180 minute;

[0035] 3) Pressure filtration, drying and crushing to obtain flaky aragonite calcium carbonate.

[0036] Sample electron microscope scanning see attached image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com