Full-automatic wire harness crimping machine

A crimping machine, fully automatic technology, applied in the direction of connection, connection by deformation, line/collector parts, etc., can solve the problems of affecting the strength of the wire, corrosion of the connector and wire, poor precision, etc., and achieve production efficiency High, stable quality, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

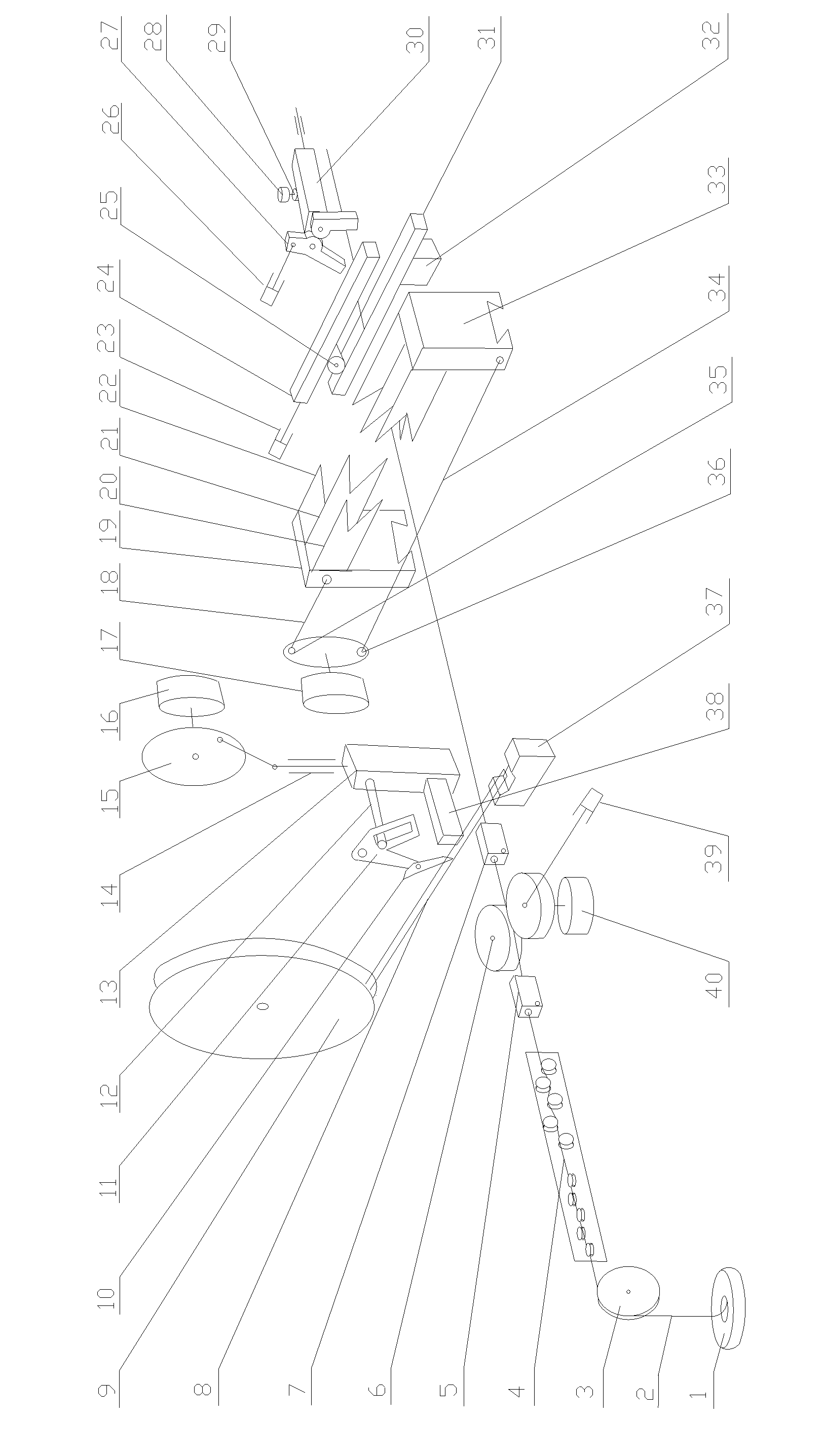

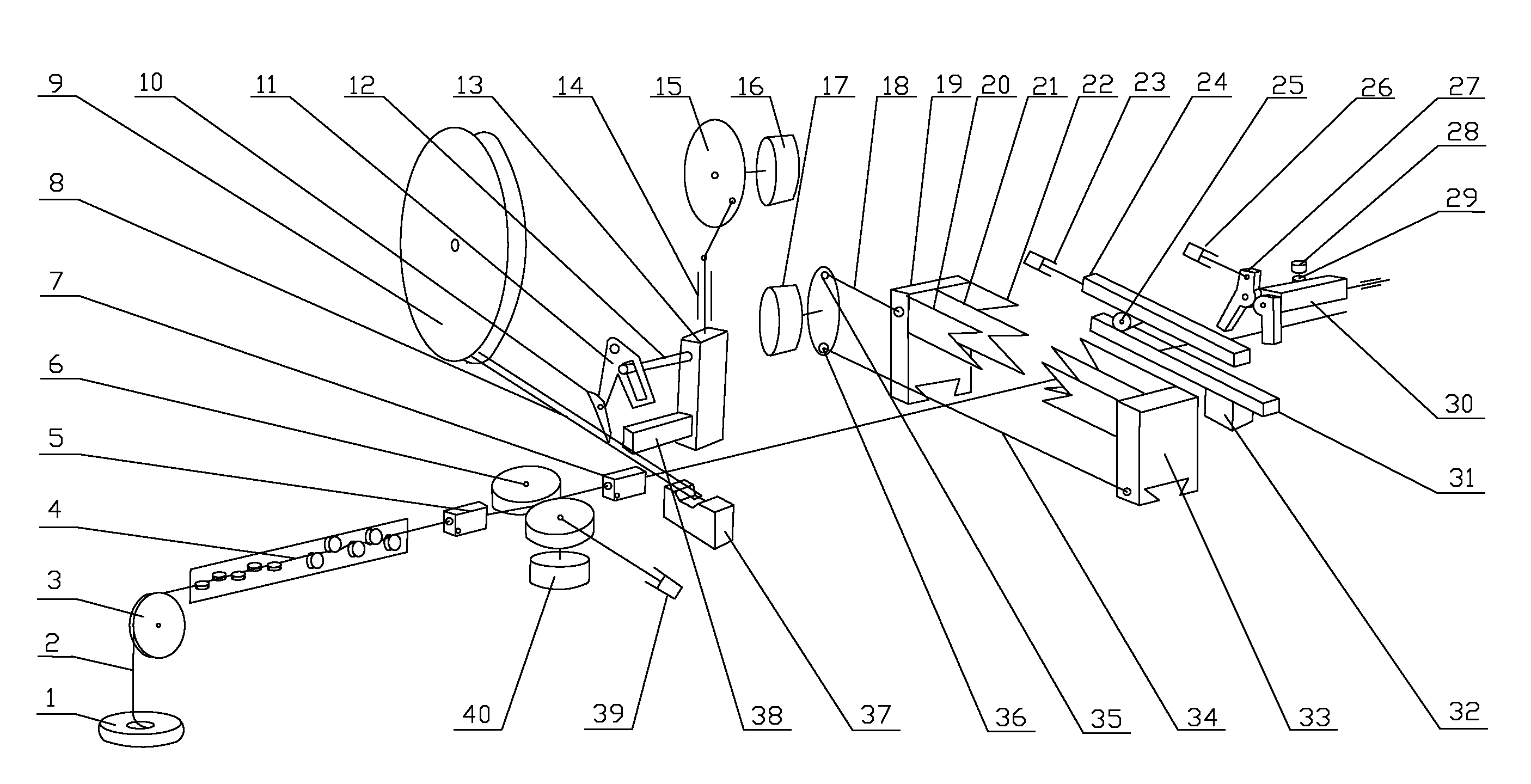

[0018] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0019] See figure 1 , a fully automatic crimping machine, a wire feeding device, a connector crimping device, a cutting and peeling device, and a wire feeding device are sequentially arranged on the frame according to the wire feeding direction. As a further function improvement, a head rubbing device can also be provided between the cutting and peeling device and the wire conveying device.

[0020] The wire feeding device includes grooved guide wheels 3 and wire feeding mechanism arranged in sequence according to the wire feeding direction. The wire feeding mechanism includes a wire feeding pair wheel 6, and a wire feeding stepping motor 40 and a compression cylinder 39 are connected to the wire feeding pair wheel 6. . Groove guide wheel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com