Method for recovering stagnant coal pillars left by breast type coal mining method

A recovery method and coal pillar technology, applied in ground mining, mining equipment, earth square drilling and mining, etc., can solve the problems of less practical and theoretical research, and achieve the effect of flexible process, good adaptability and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

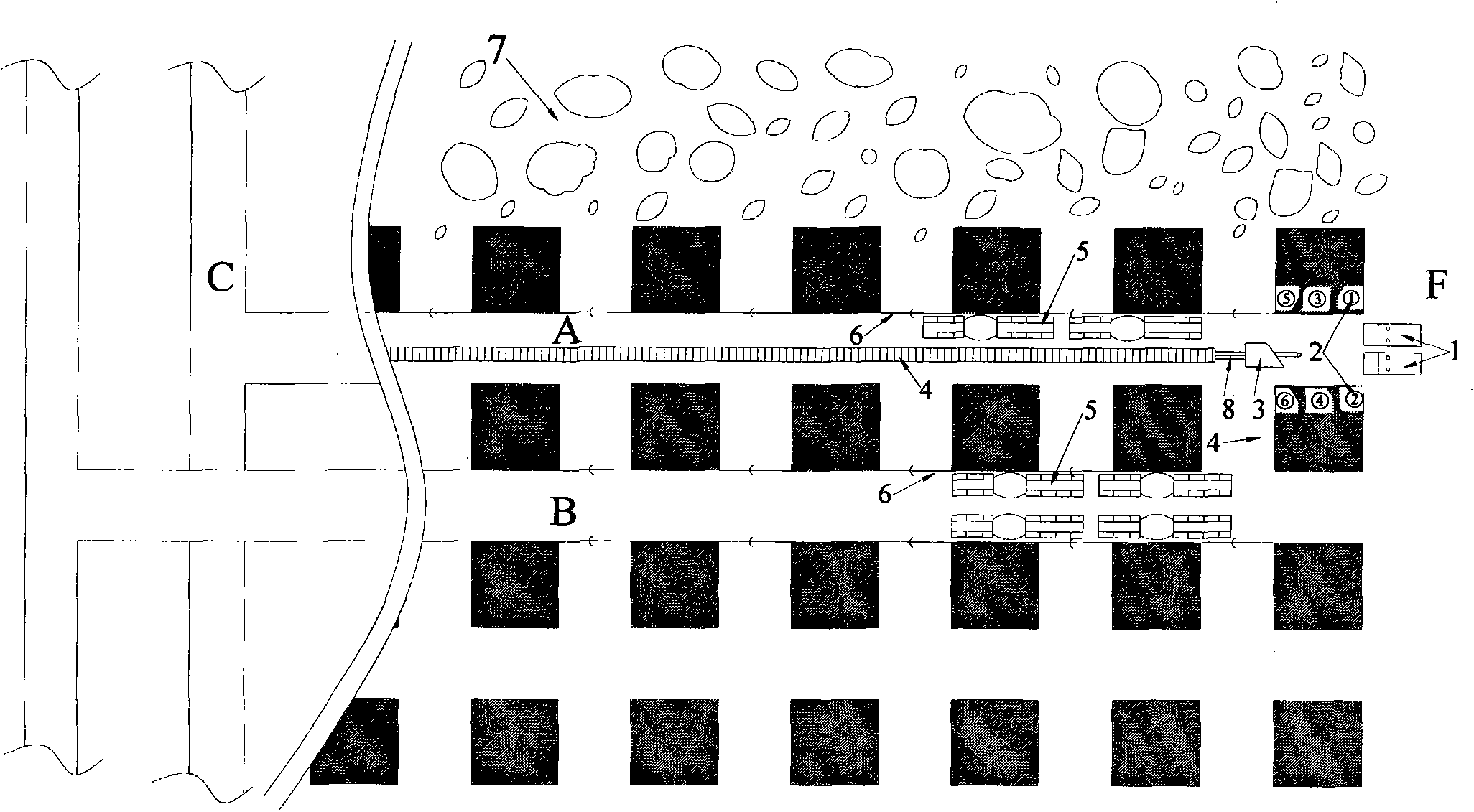

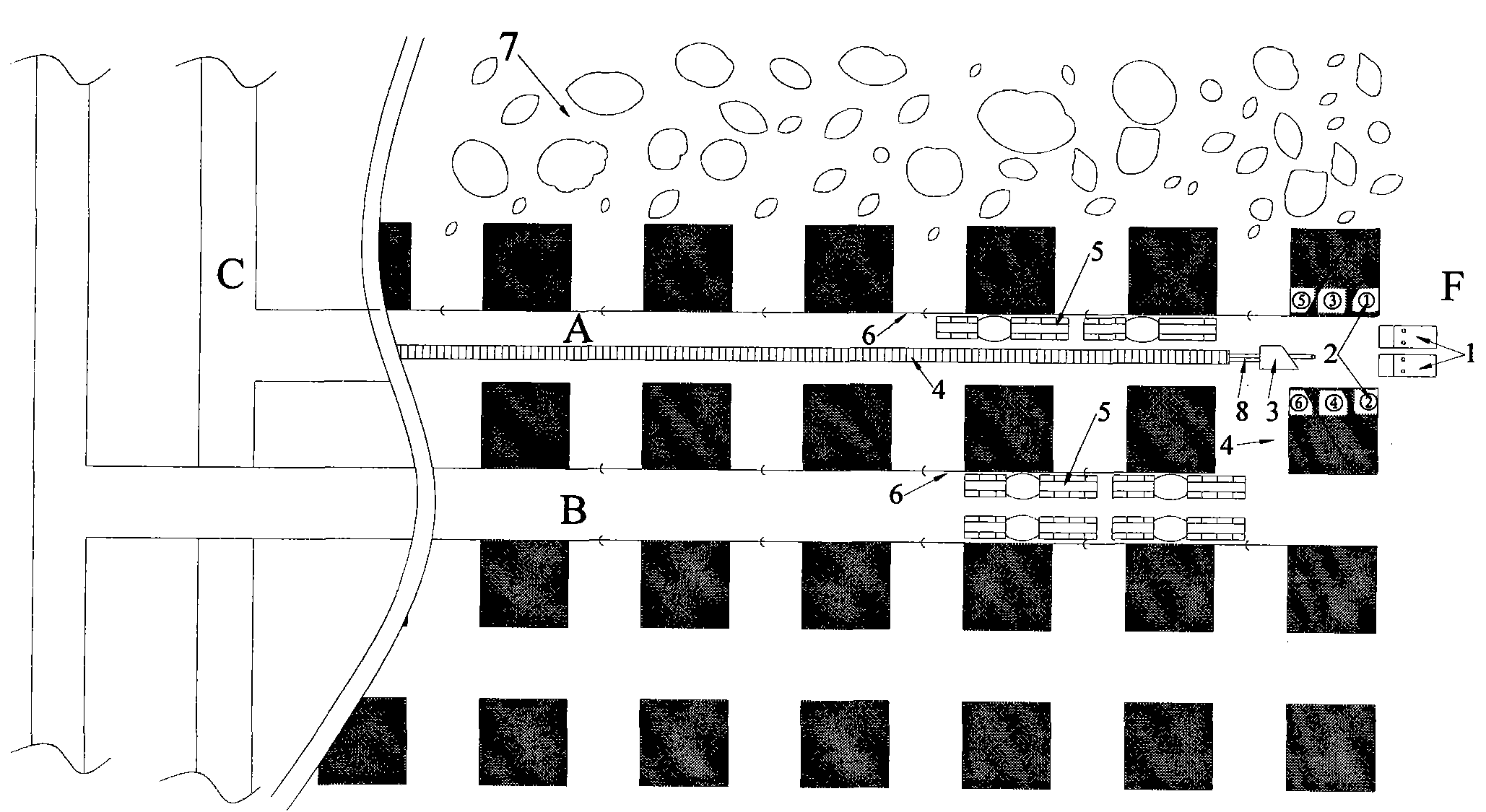

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0018] The sluggish coal pillar recovery method left over by the room type coal mining method of the present invention:

[0019] 1. Before mining, at the intersections with relatively large exposed areas (length or width greater than 8m) in coal houses and connecting roadways, use anchor cables to strengthen the support. The anchor cables are 7 strands of Φ5mm high-strength steel strands, and the pallets are 12# channel steel processing, length 250mm, backing plate is 8mm steel plate, specification 50×50mm, row spacing between anchor cables is 2500mm×2500mm; The speed K2350 drug roll is behind), and the anchor cable is anchored into the stable rock formation on the roof of the coal seam for no less than 1500mm.

[0020] 2. Recover the coal mining face in different areas, every three rows of regular coal pillars is a layout unit, starting from the leftov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com